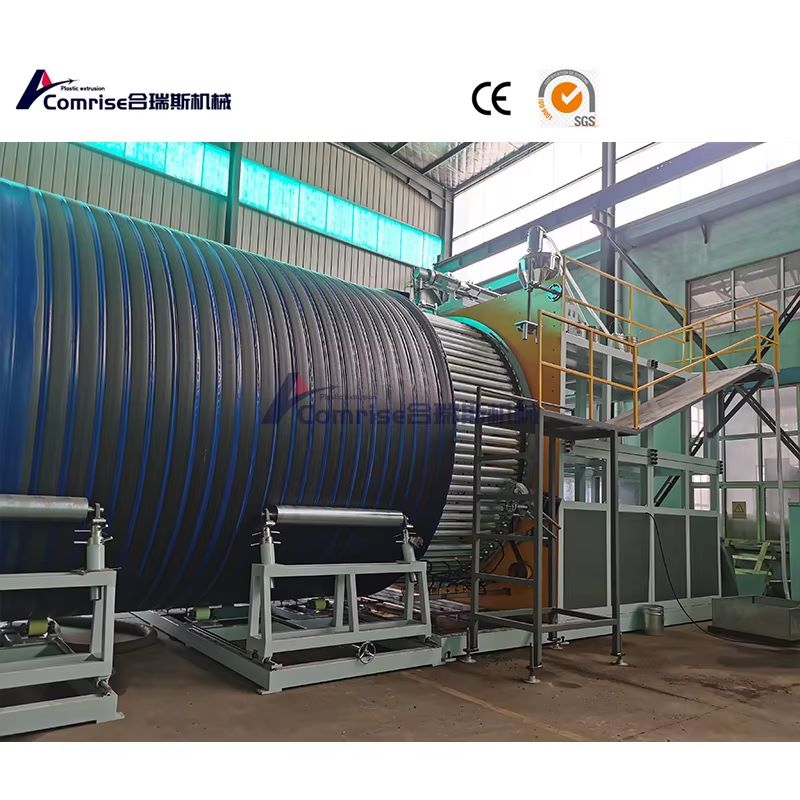

China Plastic HDPE Hollow Wall Spiral Winding Pipe Extrusion Machine Manufacturer, Supplier, Factory

We try for excellence, services the customers", hopes to become the ideal cooperation team and dominator company for staff, suppliers and buyers, realizes value share and continuous marketing for Plastic HDPE Hollow Wall Spiral Winding Pipe Extrusion Machine,Structured Wall Spiral Pipe Production Machine,Hollow-Wall Winding Pipe Extrusion Machine,Large Diameter HDPE Double Wall Spiral Winding Pipe Extrusion Machine,HDPE Large Diameter Hollow Wall Tube Making Machine, In purchase to expand our international market, we mainly provide our oversea prospects Top quality performance items and assistance.

Plastic HDPE Hollow Wall Spiral Winding Pipe Extrusion Machine, Since the establishment of our company, we've got realized the importance of providing good quality merchandise and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down individuals barriers to ensure you get what you want to the level you expect, when you want it.

Hot Products

High Configuration and High-speed 20-110mm HDPE Pipe Machine

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. High configuration and high-speed 20-110mm HDPE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe production50-160mm Pe Pipe Machine

China Comrise's 50-160mm Pe Pipe Machine is the ultimate pe pipe production machine for any business. Its efficiency, speed, ease of maintenance, and stable running process make it a game-changer in the production of pe pipes. Invest in 50-160mm high efficiency Pe Pipe Machine today and take your business to the next level.Plastic Coating Machine

Comrise Machinery, a well-known manufacturer of high-quality machinery, presents its latest offering in the field of the plastic coating machine. This plastic coating machine for corrugated pipe can efficiently and accurately coat all kinds of plastic pipes with a variety of coating materials, making it a valuable asset for any business involved in plastic pipe production.Hollow wall winding pipe machine line

Comrise china fasctory supply HDPE hollow wall wrapped pipes have been successfully used as drainage pipes to replace cement pipes and cast iron pipes, and have broad market prospects. Our company is an authoritative manufacturer of large-diameter hollow wall winding pipe production lines in China,Hollow wall winding pipe machine line with strong technical advantages and rich experience in implementing production and installation. The equipment design is advanced, the configuration is high-end, the operation is reliable, the service life is long, and the output of the same model is far higher than the industry level. Especially for ultra large diameter models, we have rich experience and can meet the needs of large high-end customers at home and abroad. The performance indicators of the production line have reached the international leading level.Hollow wall winding pipe machine

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, Hollow wall winding pipe machine, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line , the plastic coated corrugated pipe production line,PE black jacket insulation pipe production line and PE sheet/board production line, . HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.160 450mm Pe Pipe Production Line

In today's rapidly evolving world, the demand for high-quality products that serve the needs of modern society is higher than ever. China supplier comrise Machinery's 160 450mm pe pipe production line is a state-of-the-art technology designed to cater to the growing demand for sustainable, efficient, and durable piping systems worldwide.