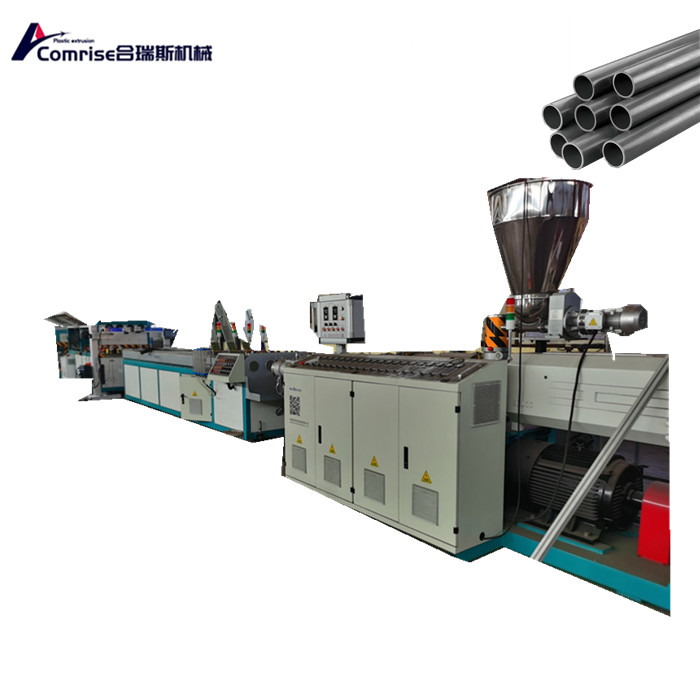

PVC Pipe Making Machine

Send Inquiry

Technical features and advantages

Special screw structure for efficient plasticization of different types of formulations.

The spiral mold reduces the number of weld seams on the pipeline, and the high compression ratio ensures high density and good mechanical properties of the pipeline.

The planetary cutting machine uses both mechanical and hydraulic feeding methods to feed the blades, and synchronously cuts and chamfers.

Flexible use of conical and parallel extruders, suitable for pipelines with different pressure levels and CaCO3 conditions.

Use efficient single or double chamber vacuum and cooling tanks.

Adopting servo/variable frequency speed regulation and independent multi track structure traction to ensure uniform pipe tension and no deformation.

As a leading manufacturer of PVC Pipe Making Machine, Comrise meets the needs of PVC Pipe Making Machine manufacturers. Our highly advanced machines have impressive output capabilities ranging from 75 kg/h to 350 kg/h. To ensure excellent performance, we offer a variety of high-capacity PVC Pipe Making Machine with screw diameters ranging from 51/105 millimeters to 65/132 millimeters. The conical extruder adopts a highly advanced and innovative screw structure to produce high-quality pipes with the lowest scrap rate. In addition, our pipe extruder adopts a sturdy design and structure, which can withstand harsh work. The integrated PLC control system in our PVC/CPVC pipe making machine improves its performance and also provides user-friendly operation.

Our PVC Pipe Making Machine is made of the best materials, which helps ensure the production of the highest quality products. Our cPVC uPVC pipe (twin-screw) - cone equipment is not just a production facility. This demonstrates our commitment to innovation, sustainable development, and excellence. With our new CPVC UPVC double pipe production line factory, we are more capable than anyone else to meet the needs of our customers.

Characteristics of PVC machine

Low price and high performance: We strive to provide cost-effective solutions without compromising quality or performance.

Multi functional extruder: Our unique extruder design allows for the processing of CPVC and UPVC materials, providing versatility and convenience.

Triple chrome plated mold: Our machine's mold components are coated with a triple chrome plated coating to ensure durability and service life.

At Comrise, we are committed to providing the most advanced plastic processing machinery to meet the diverse needs of our valued customers. We firmly focus on quality, performance, and customer satisfaction, and continue to be a trusted brand in the industry.

core technology

---Automatic extrusion system:

Advanced twin-screw extruders ensure precise temperature control and uniform material mixing to achieve perfect pipe wall thickness and structural integrity. Compatible with multiple PVC formulations (UPVC, CPVC, and recycled materials).

---High speed calibration and cooling:

The vacuum calibration tank and precision cooling system ensure dimensional accuracy and smooth surface finish.

Rapid cooling can minimize the production cycle while maintaining product quality.

---Intelligent control and monitoring (optional):

The PLC and HMI interface can adjust the diameter, wall thickness, and production speed in real time.

Automatic fault detection can reduce downtime and waste.

---Multi functional output:

Produce pipes ranging from Ø 16mm to Ø 800mm for applications such as drainage, drinking water, electrical conduits, and industrial pipelines.

GET A QUOTATION NOW