Products

- View as

HDPE PE COD Cable Porous Pipe Making Machine

The Comrise HDPE PE COD Cable Porous Pipe Making Machineis used to produce spiral and corrugated coated sub pipes. COD pipe structure: with low friction HDPE microtubes inside and corrugated pipes coated on the outside. This pipeline has high pressure resistance, is easy to bend, lightweight, and easy to construct, making it an ideal cable conduit. COD pipes are widely used as underground conduits for electrical wires and cables in bridges and building systems. The machine adopts efficient extruder and co extrusion technology to form COD pipes in one step, with smooth inner and outer surfaces and superior quality.

Read MoreSend InquiryPVC Pipe Making Machine

Comrise Machinery offers a full range of PVC Pipe Making Machine, suitable for U-PVC and C-PVC. The PVC pipe extrusion production line includes a conical twin-screw extruder, a spiral die head, a vacuum tank, a water tank, a traction machine, a dust-free cutting machine or a planetary cutting machine, and an expansion machine with O-ring sockets or rectangular sockets or U-shaped sockets. Our PVC pipe making machine can produce pipes ranging from 16mm to 630mm, with a wall thickness range of 1-30mm. If you are interested in our PVC pipe extruder, please contact us and get a free quote immediately

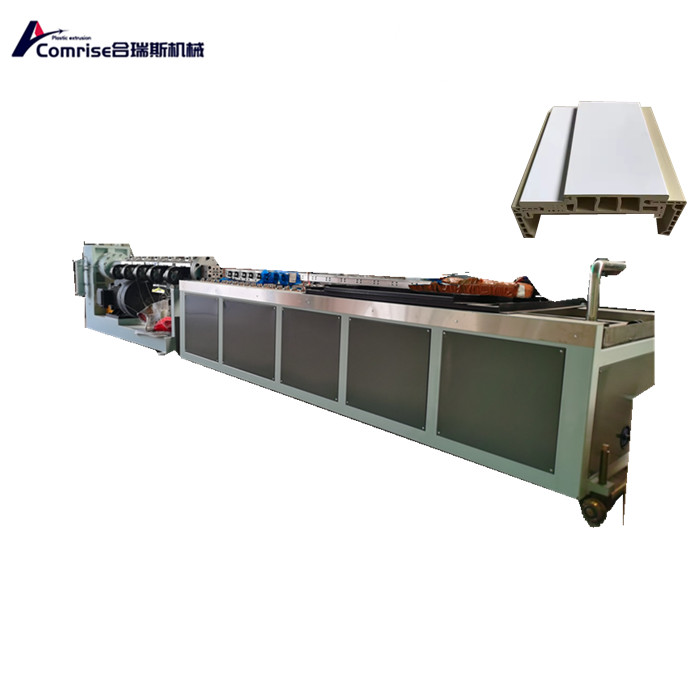

Read MoreSend InquiryDoor and window panel profile making machine

Comrise factory Door and window panel profile making machine mainly consists of a conical twin-screw extruder, a cooling table, a traction machine, a cutting machine, and a stacker crane. Having different molds, we can produce various UPVC profiles, such as PVC window and door profiles, PVC wall panels, PVC window sills, cabinet door panels, curtain boxes, PVC trucks, cable conduits, PVC skirting boards, PVC protective corners, etc. And by replacing the screw barrel and mold, PVC based wood plastic products can also be produced, such as wood plastic wall panels and wood plastic windows.

Read MoreSend InquiryDouble Wall Corrugated Pipe Making Machine

Comrise factory Double Wall Corrugated Pipe Making Machine is developed and manufactured by Comrise, using a molding machine template design. The product is air-cooled through a gear transmission module, with fast molding speed, uniform corrugated shape, consistent joints, and smooth inner and outer walls.

Read MoreSend InquiryHigh Speed Single Wall Corrugated Pipe Prodction Line

Comrise factory series of plastic High Speed Single Wall Corrugated Pipe Prodction Line meticulously developed by our company, through the gear drive mould, water cooling in the water trough of the forming machine so that the production of the pipe molding speed, uniform corrugated shape, smooth inside and outside the wall. The production speed is 8-15 meters per minute.

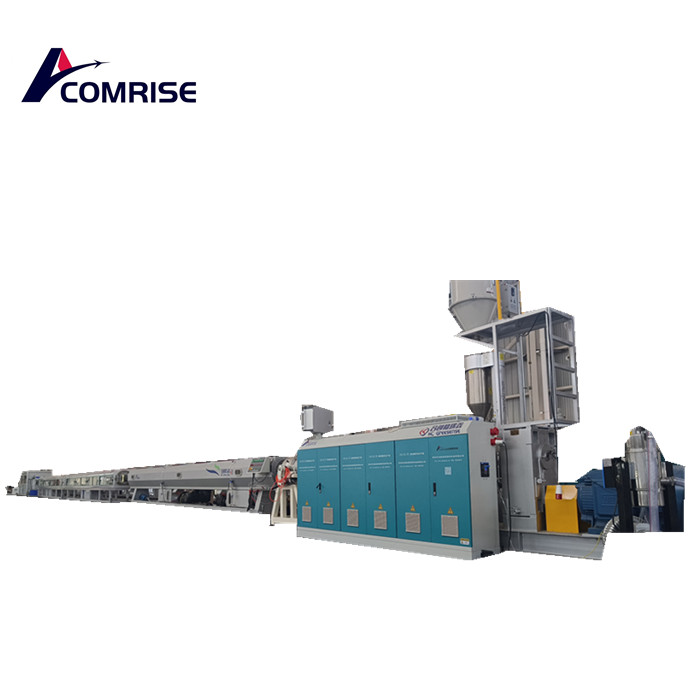

Read MoreSend Inquiry110mm HDPE Pipe Machine

Comrise factory 110mm HDPE Pipe Machine machine Manfacture configuration is different as per produced pipe diameter range. For small diameter range like 20-63mm, there are several different speed models for option, the highest production speed is up to 60m/min for 20×2.0mm HDPE pipes. Big diameter HDPE pipe extrusion line can be designed as two layer co-extrusion type or 3 layer co-extrusion type. Pipe coiler is equipped as an option, to coil pipe size from 16-32mm, or 20-63mm or much big up to 110mm.

Read MoreSend Inquiry