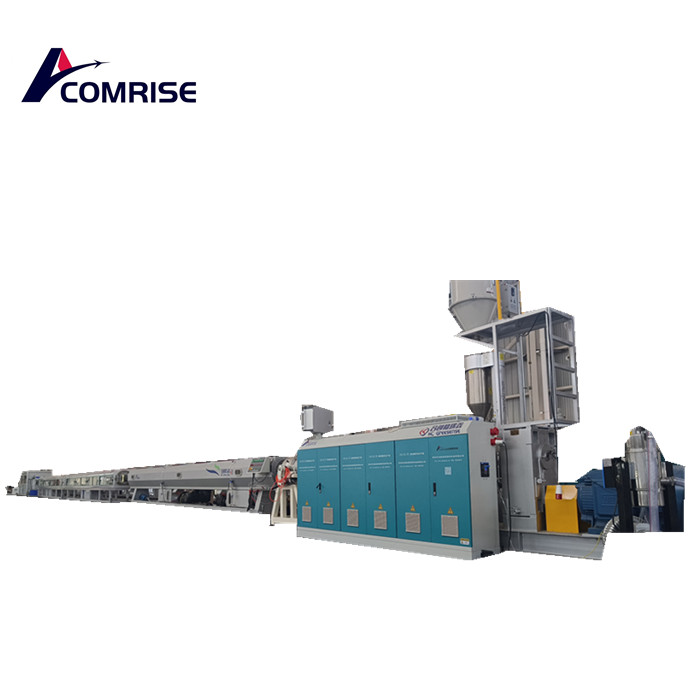

110mm HDPE Pipe Machine

Send Inquiry

High Speed HDPE Pipe Production Line

Comrise factory has focused on plastic pipe extrusion technology for more than 20 years, especially for high speed pipe line and multi-layer pipe line.

For small diameter 110mm HDPE Pipe Machine, the production speed can reach to 60m/min, in order to increase the production efficiency, reduce production cost, such as labor, electric and water consumption etc.

Maximum HDPE pipe diameter we can made is up to 630mm. For big diameter, the extrusion line can be mult-layer coextrusion type, like two layer co-extrusion or 3 layer co-extrusion.

Gravimetric material dosing system can be equipped to save raw material, shorten start up time, and increase pipe quality level etc.

1) Special designed high efficient five-section type screw and barrel, ensuring the rapid plasticizing & dispersion effect, and realizing high speed production.

2)Gravimetric material feeding system is to control material feeding according to pipe parameter & line production speed, to get high qualified pipe with constant weight per meter. It’s also have other benefits, such as shortening start-up time, saving raw material, simplifying operation.

3)Spiral pressure-storage die head, ensuring the stability of high speed extrusion and produced pipe quality.

The die head is designed different as per pipe pipe structure and diameter range, like high speed extrusion die head, two layer co-extrusion die head or three layer -co-extrusion die head

4)Different type pipe coiler is equipped as an option, like coiler for 16-32mm or coiler for 20-63mm, or even big up to 110mm HDPE pipe coiling.

5)SIEMENS PLC programmable computer control system, which could ensure the whole line high-speed synchronous control and its stable & reliable running.110mm HDPE Pipe Machine

According to customer's specific requirement, Comrise Machinery produce the 110mm HDPE Pipe Machine with Siemens PLC and touch screen for controlling the complete machine. There is also meter weight auto control system. This device will guarantee the PE pipe with exact wall thickness as required. The extruder is SJ65/33 with 55Kw AC motor.

Machine features

The optimal spiral structure of the feeding throat increases the height of the extruder

The output of

2. Accurate temperature control system ensures material melting performance

3. Unique screw design can achieve better plasticization and high-quality products

4. A precisely designed high torque gearbox ensures stable operation

5. H-shaped frame to reduce the number of extruders Vibration o

6. Advanced PLC system for synchronization and automation

7. Adopting automatic water temperature and level control, as well as vacuum and cooling tanks The special independent filter

8. Provide a stable traction device with 2-12 caterpillars

9. Provide options for sawless and chipless cutting

10. Low energy consumption, excellent performance, and easy maintenance