PP Pipe Manufacturing Machine

Send Inquiry

High Efficiency 315-630mm HDPE PP pipe manufacturing machine is real high speed and high output machine with newest design and famous electric brands SIEMENS, SCHNEIDER, pp pe pipe machine producing for sizes from 110mm upto 315mm. pe pipe manufacturing machine line including SJ90/38 high efficency screw extruder, high torque reducer motor, precison molds, two section vacuum water tank, haul off and cutter machine. For this HDPE PP PPR pipe manufacturing machine line maximum output can reach 800kgs-1000kgs per hour.

315-630mm HDPE PP Pipe Manufacturing Machine production line composition lists:

|

NO |

Name and code name |

models |

quantity |

|

1 |

High-efficiency single-screw extruder |

XY S-H90/38 |

1set |

|

2 |

Dryer hopper |

GZ164 |

1set |

|

3 |

Auto suction loading |

JL2100 |

1set |

|

4 |

Siemens PLC control system |

HDPE 630 |

1set |

|

5 |

Single-screw line-marking extruder |

XY S-30/25 |

1set |

|

6 |

pipe extrusion die head |

HDPE 315-630 |

1set |

|

7 |

Mouth mold, core mold |

Φ 315~Φ 630 |

6sets |

|

8 |

Water ring diameter set |

Φ 315~Φ 630 |

6sets |

|

9 |

Vacuumwater tank |

Z-PE-630-12 m |

1set |

|

10 |

Calibration device |

standard |

1set |

|

11 |

Spraywater tank |

PL-630-6 m |

2sets |

|

12 |

Six-claw crawler tractor |

QY-630 |

1set |

|

13 |

Chippless cutting machine |

QG-630 |

1set |

|

14 |

Auto stacker |

CPJ-630 |

1set |

|

15 |

weight meter controller |

GMS20 |

1set |

315-630mm HDPE PP Pipe Manufacturing Machine parameters:

|

Model |

Pipe Dia |

Extruder Model |

Motor Power |

Max.output/h |

|

HSPE-63 |

20-63 |

HSH60/38 |

90 |

450 |

|

HSPE-110 |

20-110 |

HSH60/38 |

110 |

500 |

|

HSPE-160 |

40-160 |

HSH60/38 |

110 |

500 |

|

HSPE-250 |

50-250 |

HSH75/38 |

160 |

680 |

|

HSPE-400 |

160-400 |

HSH90/38 |

250 |

1000 |

|

HSPE-630 |

280-630 |

HSH90/38 |

280 |

1100 |

|

HSPE-800 |

315-800 |

HSH120/38 |

315 |

1300 |

|

HSPE-1200 |

500-1200 |

HSH120/38 |

355 |

1400 |

|

HSPE-1600 |

1000-1600 |

HSH90/38&HSH90/38 |

250+250 |

2000 |

|

HSPE-2000 |

1000-2000 |

HSH90/38&HSH90/38 |

280+280 |

2200 |

GET A QUOTATION NOW

315-630mm HDPE PP Pipe Manufacturing Machine detail specifications:

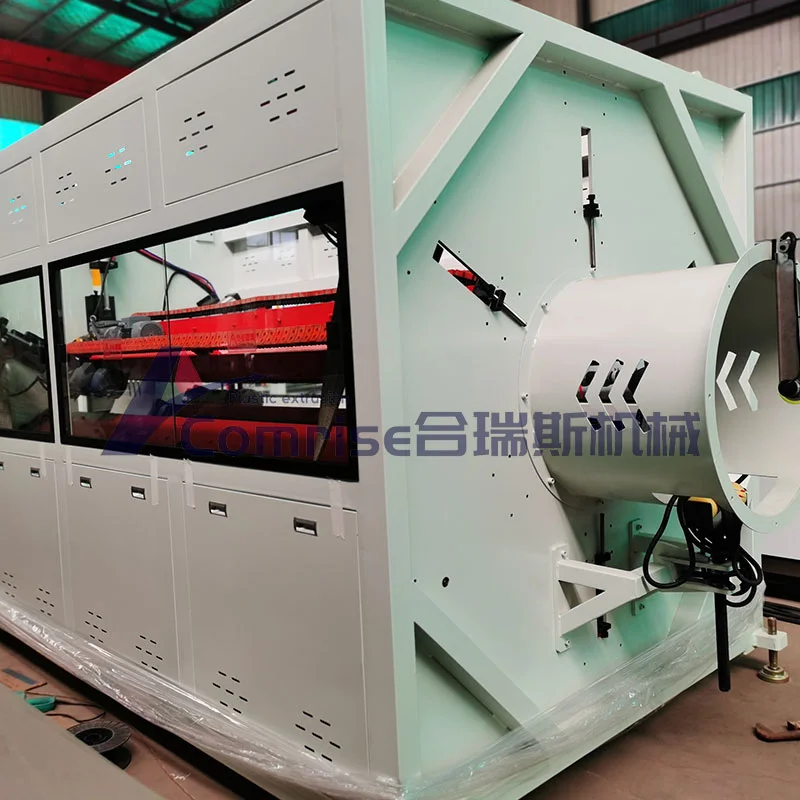

SJ75/38 High efficiency single screw extruder

Srew adopt alloy screw, the inner surface of the screw and barrel is processed with nitriding, alloy spraying, Xinhengli or SIEMENS energy-saving motor 250kw, Guomao high-torque reducer, vertical hard-tooth surface reduction box , and the gear box is strengthened by spiral reduction and grinding surface gear. Level braking, the control system adopts Schneider inverter (or equivalent brand),Siemens low voltage electrical components.

Siemens contactor,customer can choose Meter weight control, Siemens PLC control system or OMRON digital control system

SIEMENS PLC control

The running time of the entire PE pipe production line equipment is programmed by PLC, and is equipped with a good human-machine interface. All process parameters can be set and displayed through the touch screen.

Schneider inverter

Siemens contactor

Gravimetric weight meter control by PLC

Energy-saving ceramic heating ring and Cooling fans

Pipe extrusion Die head mold

Spiral replaceable pe pipe die head molds with core and bars Specifications: φ 315mm,355mm-400mm-450mm-500mm-560mm-630mm

The blue die head designed for HDPE pipes has the characteristics of low melt temperature, good mixing performance, low mold cavity pressure and stable production.

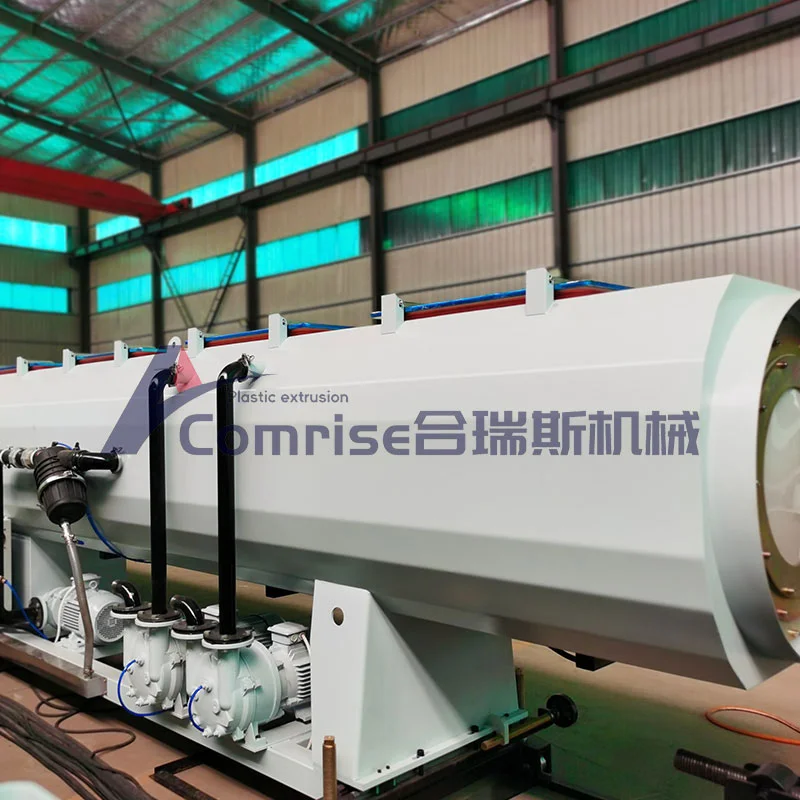

WATER TANK ADVANTAGES:

Low vacuum setting, the residual stress after molding is sufficient

Abnormal vacuum has the siren alarm function

The high-precision digital display vacuum table is used

Strong spray cooling and cooling evenly

Optimize the design of the cooling line and the vacuum system

Using brushed stainless steel SUS304 box exterior appearance, smooth line

The thickness of the stainless steel box is 5mm

Plastic large filter system, easy to timely clean up the pipeline blockage

Water temperature and water level automatic control device

longitudinal wire rod moving device

Vacuum water tank 8+4meters

Front and rear vacuum setting length: 2m + 8m

Vacuum degree: -0.03~0.08MPa

Vacuum pump power of the front section water tank: 7.5KW 1 set

Power of water pump in front water tank: 7.5KW 1set

Power of rear water tank pump: 7.5KW 2 sets

Vacuum pump power of the rear water tank: 7.5KW 2 sets

Mobile motor power: 1.5KW

Spraying water tank 6meters

Strong spray cooling

Strong spray cooling and cooling evenly

Optimize the design of the cooling line and the vacuum system

Crushed stainless steel SUS304 box exterior beautiful, smooth line

Plastic large filter system, easy for timely cleaning of pipeline blockage

Spray box length: 6,000 mm

Water pump power: 7.5KW, 1 set

Six claws pe pipe hall off machine

Six crawler type traction, wide tank chain rubber block, increase the stable traction force

Quality brand encoder length device

AC-frequency conversion control system

has good stability, high precision and high reliability.

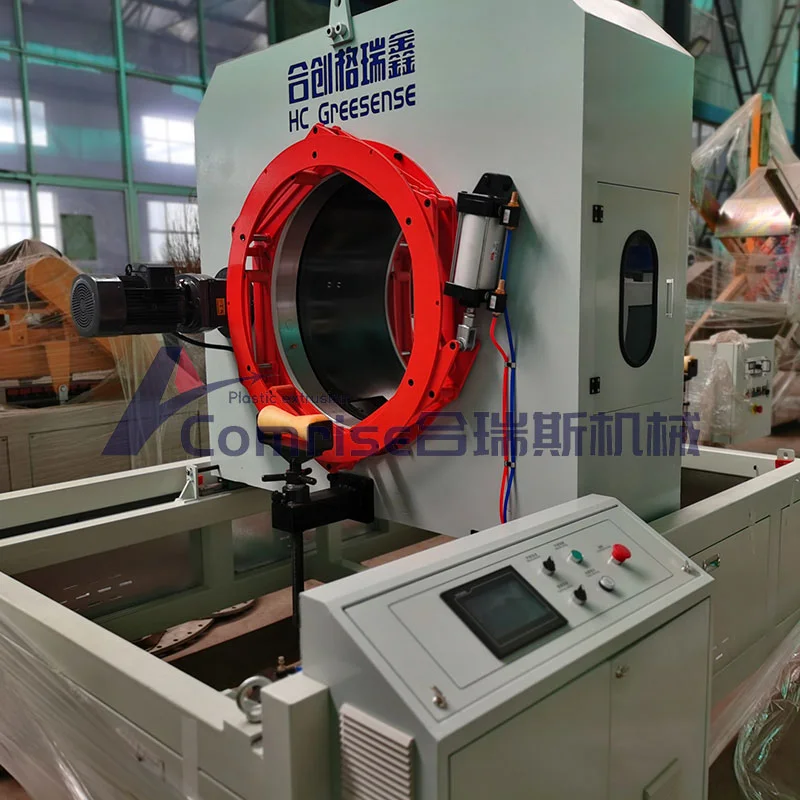

No dust cutting machine

Power of rotary motor: 5.5 kW

Cutting range: φ 355- φ 630

Max. cutting thickness: 60mm

Production pipe specification: see the product specification table

Basic mechanical design feature for cutting machine:

Dust-free hydraulic knife cutting (note: appropriate flip the end surface of dust-free cutting products)

Pneumatic rotating clamping structure without replacement of molds

Cutting machine with safety shield

Siemens programmable controller control system

AC variable frequency conversion governor

Automatic flip rack

315-630mm HDPE PP Pipe Manufacturing Machine line have detial photos for auxiliary parts vacuum pumps, water pumps, tractor V type block to make pipe round shape, and cutter details.

GET A QUOTATION NOW

315-630mm HDPE PP Pipe Manufacturing Machine product feature and applications:

manufacture new technology high speed 315-630mm HDPE PP pipe manufacturing machine, MPP electric pipe production line, pe water supply pipe machine, pe pipe extrusion machine has reliable performance and high production efficiency. The finished pipes are mainly used in agricultural water supply and drainage, building water supply and drainage, cable laying, etc.

The 315-630mm HDPE PP pipe manufacturing machine is composed of high efficency single screw extruder, vacuum sizing water tank, tractor, cutting machine, and pipe bracket.

The 315-630mm HDPE PP pipe manufacturing machine with high efficency single screw extruder, tractor adopt imported frequency conversion speed control device, and the vacuum pump and traction motor are all made of high-quality brands. The traction machine has two claws, three claws, four claws, six claws, eight claws, ten claws, twelve claws according detail pipe diameters. The cutting machine can choose chipless cutting, saw blade cutting or planetary cutting etc. The planetary cutting machine adopts fully automatic computer numerical control, which has the advantages of convenient operation and reliable performance.

We can provide customers valuable technical support to meet different requirements , for example , by replacing some parts to produce inner wall spiral pipes, inner wall hollow pipes and core layer foam pipe, for different material like PP, PE, ABS, PPR, PEX etc.

About our factory&workshop

Comrise machine are a new generation father-son plastic extrusion machine manufacture. Father was the first group of technicians to enter the plastic extrusion industry. Son and daughter also majored in mechanical design and drawing at the university. After graduation, they have been engaged in the production, manufacturing , design and development of plastic extrusion machines. Till now they have already more than 30 years experience in plastic machinery field with more experience for HDPE PP PPR pipe manufacturing machines and pe spiral wrapping pipe machines.

About our patent certificates

Delivery photos

Customer photo

Customer feedbacks

Requests for questions(RFQ)

Q1: Are you manufacture or trading company ?

A1:We are manufacture of machine.

Q1:Question: What advantages of your machine?

A1:Quality 100% assured, famous electric brand, 24h time techincal support, Flexible payment term, Local consult office.

Q2: what’s the company paymet term?

A2: 30% deposit T/T,70%balance before shipment, Letter of Credit, west union , instgram , third party.

Q3: how long will it take to delivery after payment?

A3: Normaly 35-50 days manufacture time depend on certain machines.

Q4: Warranty terms of your machine?

A4: 12 months, starting from the machine receipt in customer's warehouse Free-of-charge of spare parts during warranty period.

Q5: What after sale service will offer ?

A5: Pre-sale communication → Design proposal, signature confirmation→ Customized production→ Test machine before shipment →Package & delivery→ Engineer installation→Training operator → Technical support