Call Us

+86-13780696467

Email Us

sales@qdcomrise.com

China Pe Pipe Manufacturing Machine Manufacturer, Supplier, Factory

We've been also focusing on improving upon the stuff management and QC program to make sure that we could hold fantastic gain in the fiercely-competitive enterprise for Pe Pipe Manufacturing Machine,Pe Pipe Maker Machine,Pe Conduit Pipe Machine,Pe Drain Pipe Machine,Plastic Pe Pipe Making Machine, Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

Pe Pipe Manufacturing Machine, Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

Hot Products

PVC Fiber Reinforced Soft Pipe Extrusion Line

COMRISE PVC Fiber Reinforced Soft Pipe Extrusion Line is designed to produce PVC soft spiral reinforced pipe, which is widely used in industry , agriculture , architecture , irrigation market and so on.We are china factory PVC Fiber Reinforced Soft Pipe Extrusion Line consists of two sets single screw plastic extruders, mould, forming machine,cooling water tank, rotatory haul off machine and winder.Pipe Machine

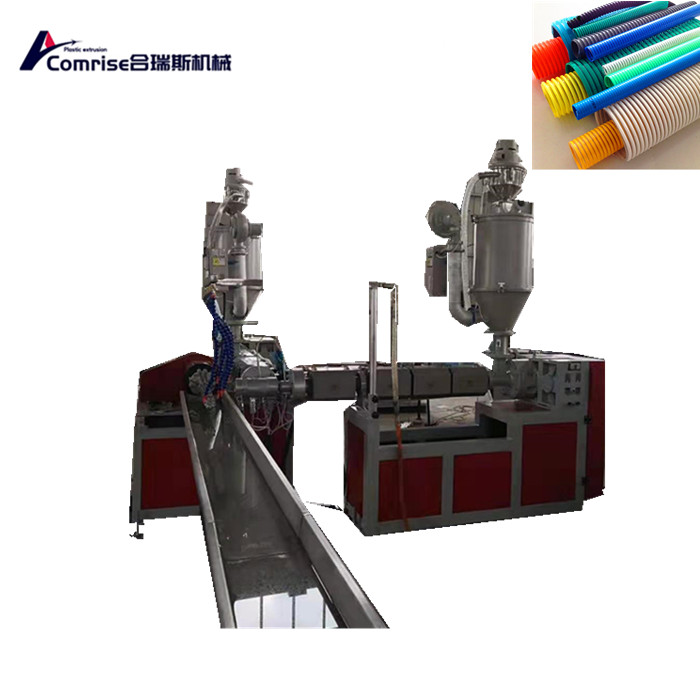

Comrise Machinery is a leading Chinese manufacturer specializing in plastic Pipe Machine extrusion equipments and Pipe Machine production lines, with extensive industry experience and technical expertise. Comrise are committed to providing global customers with high-quality, high-performance solutions for plastic pipe production, catering to a wide range of applications.Good Qulaity Double Wall Corrugated Pipe Machine

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, PE large-diameter hollow-wall winding pipe production line, Good Qulaity Double Wall Corrugated Pipe Machine, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line, the plastic coated corrugated pipe production line, PE black jacket insulation pipe production line and PE sheet/board production line. HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.Hollow wall winding pipe machine

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, Hollow wall winding pipe machine, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line , the plastic coated corrugated pipe production line,PE black jacket insulation pipe production line and PE sheet/board production line, . HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.Pe Spiral Winding Pipe Machine

COMRISE specialize in providing advanced pe spiral winding pipe machine machinery for underground sewage construction or building usage. Comrise pe spiral winding pipe machine are used to create a variety of pipe types for different applications, such as hollow wall spiral winding, inner rib spiral winding, smooth wall winding, double plastic winding, and plastic insert steel winding. Comrise take pride in our expertise when it comes to larger diameter pipe machines, as it requires not only specialized machinery but also highly skilled professionals to operate them.Steel Belt Reinforced Spiral Pipe Production Line

Comrise Machinery is a professional supplier and manufacture for Steel Belt Reinforced Spiral Pipe Production Line, the high quality Steel Belt Reinforced Spiral Pipe Production Line inlcuding four extruders for different usage, profile extrusion, glue extrusion, this newest Steel Belt Reinforced Spiral Pipe Production Line can make pipe diameter from 300mm to 1200mm which use mostly in the market with high stiffness.

Related Search

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy