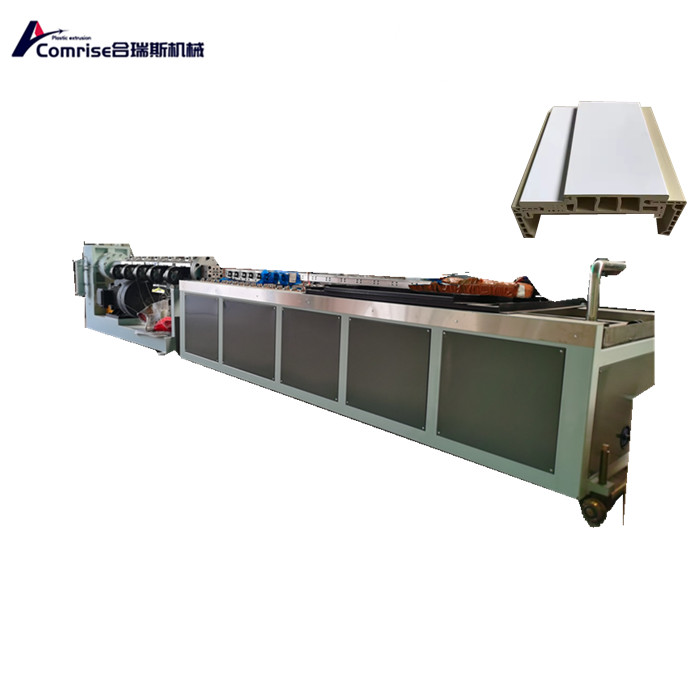

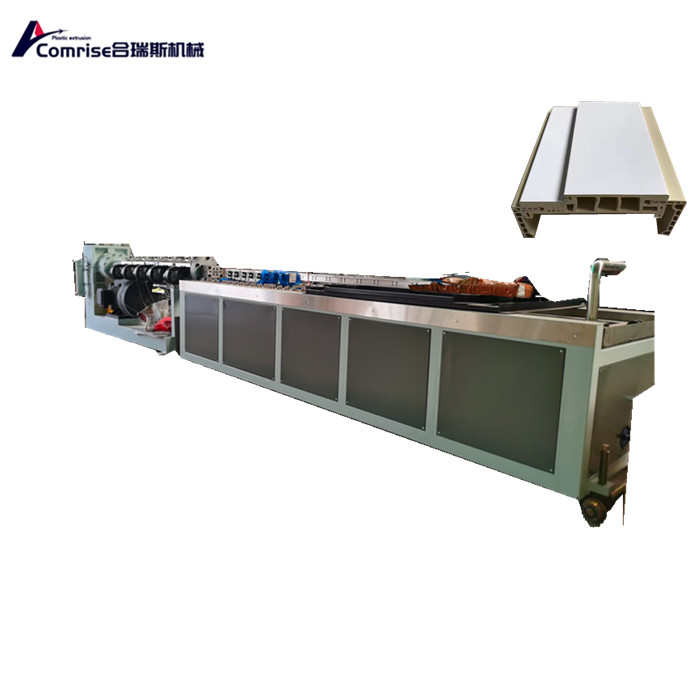

Plastic Profile Machine

Comrise Machinery China manufacture for hgih quality plastic profile machine.

Comrise are committed to offering the best customer service. Comrise team of experts is available to provide advice on the best plastic profile board machine to meet the individual requirements of our clientele. They also offer after-sale support services such as maintenance, repair, and training to ensure that clients have the best experience with their machinery.

GET A QUOTATION NOW

Plastic profile machine introduction:

SZ65/132-PVC plastic profile machine extrusion production line consists of stainless steel screw feeder, SZ65 conical twin-screw extruder, stainless steel forming mold, new cooling and shaping platform, traction and cutting machine, stainless steel stacking frame and intelligent electric control cabinet. The plastic profile board machine output of the whole set of equipment is as high as 200-250 kg per hour; it can produce PVC stone plastic floor, PVC PE WPC decking profiles, PVC window door profile and other plastic profiles. With advantages of intelligent electric control cabinet, new design calibrator, high output, one production line by changing molds can make many kinds of pvc profiles.

The plastic profile machine vacuum sizing table adopts a special enlarged vortex flow cooling system, which is convenient for cooling and shaping. The special horizontal tilt control and the unique three-dimensional adjustment control make the operation simple and better reflected. According to different molds, the sizing table can be 4 meters, 6 meters, 8 meters, 10 meters and other specifications to meet the requirements of high-speed extrusion.

The plastic profile board machine tractor adopts a unique lifting technology, and the back pressure of the upper and lower tracks is controlled. It works smoothly, has good reliability and large traction. Automatic fixed length cutting and equipped with dust collect device.

The production line has the characteristics of novel shape, reasonable structure and convenient use.

GET A QUOTATION NOW

Plastic profile board machine main parameters:

|

Model |

HRS-300 |

|||

|

Width of ceiling panel (mm) |

100, 180, 200, 250, 300 for option |

|||

|

Extruder model |

48/117 |

51/105 |

55/120 |

65/132 |

|

Main motor power |

15kw |

15kw |

22kw |

37kw |

|

Length of vacuum table(mm) |

3000/ 4000/6000/8000/ 10000mmfor option |

|||

- View as

Door and window panel profile making machine

Comrise factory Door and window panel profile making machine mainly consists of a conical twin-screw extruder, a cooling table, a traction machine, a cutting machine, and a stacker crane. Having different molds, we can produce various UPVC profiles, such as PVC window and door profiles, PVC wall panels, PVC window sills, cabinet door panels, curtain boxes, PVC trucks, cable conduits, PVC skirting boards, PVC protective corners, etc. And by replacing the screw barrel and mold, PVC based wood plastic products can also be produced, such as wood plastic wall panels and wood plastic windows.

Read MoreSend InquiryPVC Profile Window Door Frame Extrusion Making Machine

Comrise PVC Profile Window Door Frame Extrusion Making Machine mainly composed by conical Twin Screw Extruder, Cooling Table, Hauling Machine, Cutting Machine, Stacker. With different moulds, it can produce various UPVC profile, such as: PVC window door profile,PVC Profile Window Door Frame Extrusion Making, PVC wall panel, PVC window sill board, cabinet door board, curtain box, PVC trucking, cable duct, PVC skirting, PVC protection corner and so on.we are plastic machine supplier

Read MoreSend InquiryPVC Door and window panel profile machine

The Comrise factory offer PVC Door and window panel profile machine mainly consists of a conical Twin S unit E extruder, a cooling T-type machine, a Hailing Machine, a Cutting Machine, and a Stacker Having different molds, we can produce various UPVC profiles, such as PVC window and door profiles, PVC wall panels, PVC window sills, cabinet door panels, curtain boxes, PVC trucks, cable conduits, PVC skirting boards, PVC protective corners, etc. And by replacing the screw barrel and mold, PVC based WPC products can also be produced, such as WPC wall panels and WPC windows

Read MoreSend InquiryDoor and Window Panel Profile Production Line

Comrise factory Door and window panel profile production line is designed based on the latest international technology, symmetrically mixing PVC with plant fibers. Adopting an efficient conical twin-screw extruder with a forced cooling system for extrusion molding. The wooden plastic boards launched on our production line have the characteristics of green environmental protection, moisture resistance, corrosion resistance, and non deformation, making them suitable for wood processing methods and can be recycled and reused.

Read MoreSend InquiryUPVC PVC Door Panel And Window Profile Production Line

UPVC PVC Door Panel And Window Profile Production Line is mainly used for producing PVC door and window profiles, PVC/WPC floor profiles, PVC corner profiles, PVC imitation marble profiles, etc.This production line consists of twin-screw extruders, vacuum forming tables, tractors, cutting machines, laminating machines,etc., and can meet different customer requirements by simply changing the mold and extruder capacity Usage scenarios.Extremely flexible and convenient.

Read MoreSend InquiryWood Plastic Composite Decking Profile Machine

Are you in the market for a top-of-the-line wood-plastic composite decking profile machine? Look no further than Comrise Machinery. Our state-of-the-art PE WPC Wood Plastic Composite Decking Profile Machine is the perfect solution for creating high-quality decking profiles that are both durable and visually stunning.

Read MoreSend Inquiry