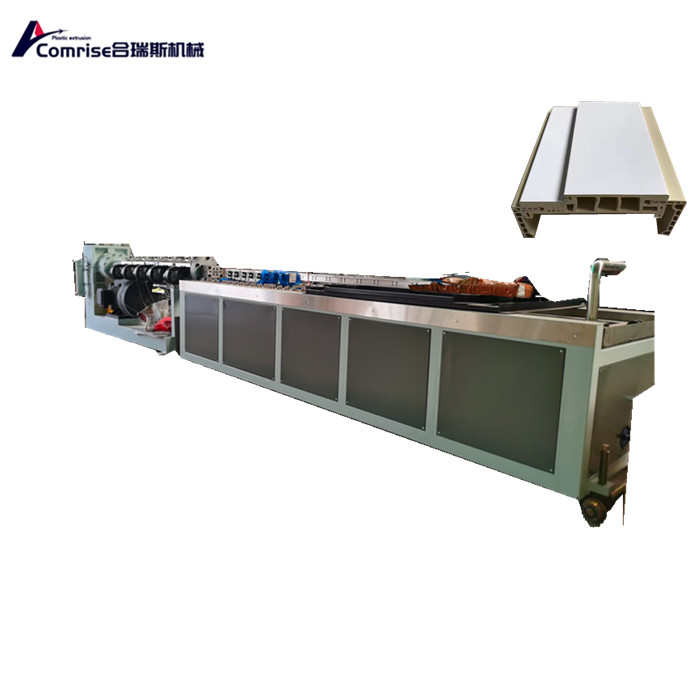

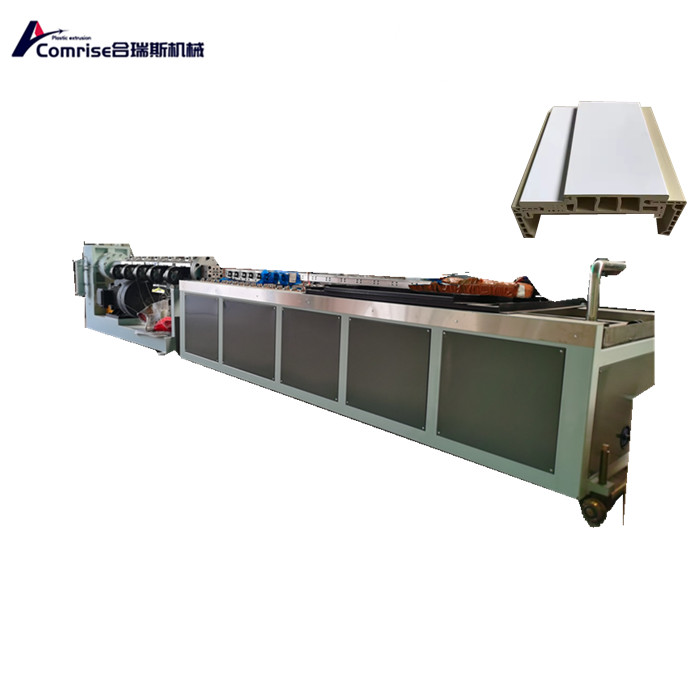

PVC Door and window panel profile machine

Send Inquiry

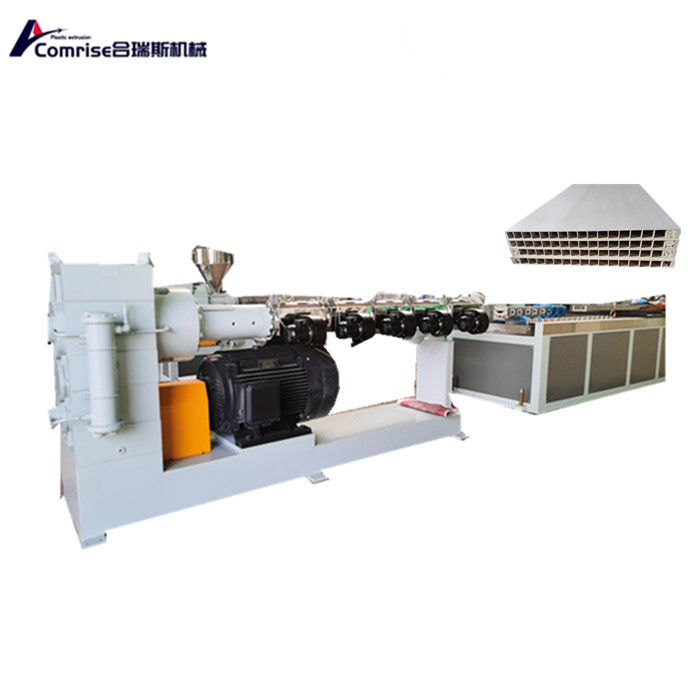

1. PVC door and window profile production line - extruder

The PVC Door and window panel profile machine extruder adopts PVC ceiling specific screws to ensure the best plasticizing effect

The extruder speed and traction speed are controlled by ABB frequency converter, which saves energy and facilitates speed adjustment

The temperature of the extruder is controlled by PID, and the temperature fluctuation is self adjusted to achieve a high level of automation we are professional machine supplier

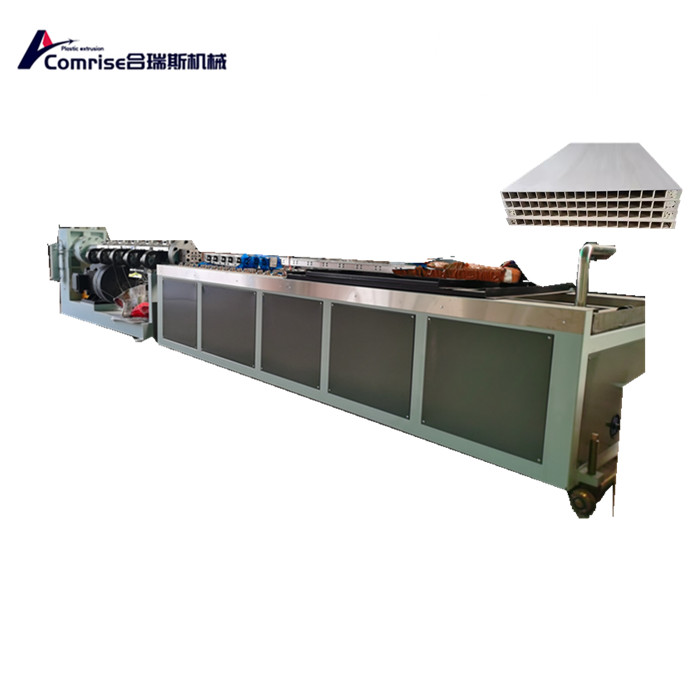

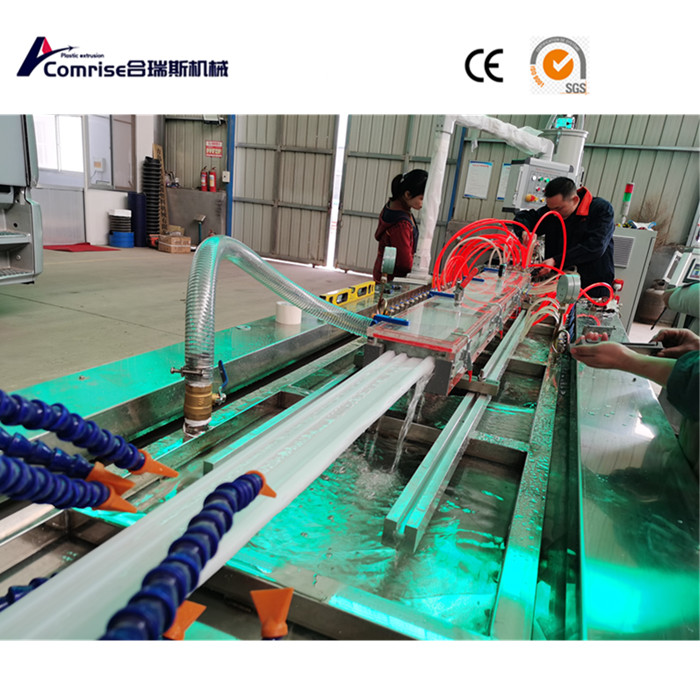

2. PVC door and window profile production line - cooling table

Using a vacuum system can achieve better cooling effects.

3. PVC door and window profile production line - traction machine&cutting machine

The tractor adopts alloy rubber blocks to strictly maintain a smooth transition of the profile.

The cutting machine is made of stainless steel material, which is wear-resistant and durable. It is also equipped with a dust removal device.

4. PVC door and window profile production line - stacker crane

PVC Door and window panel profile machine

1. World renowned brand inverter - ABB, stable and reliable.

2. World renowned brand contactor - Schneider, with reliable performance.

3. World renowned brand temperature controller - Omron, precise temperature control, reliable and durable.

4. Automatic low power consumption: The minimum total production line consumption is 25kw/hour.

5. Economical price, suitable for large-scale investment.

1. Description of PVC door and window profile extruder

A、 The plastic PVC profile extrusion production line specializes in producing PVC plastic profiles, including door and window profiles, decorative panels, micro foam profiles, and decorative panels.

b. The PVC profile machine uses PVC powder as material to produce various plastic profiles as door and window profiles, decorative profiles, etc.

c、 Our company has absorbed advanced foreign technology and developed a large-scale plastic profile extrusion production line equipped with a conical twin-screw extruder, which has the advantages of high automation, stable performance, high output and efficiency.

d、 If certain screws and molds are replaced, the PVC profile machine can directly extrude foam profiles, and the effect is much better than that of a single screw.

e. The PVC profile extrusion production line is optimized and designed with reference to the latest foreign technology, featuring uniform plasticization, low cutting rate, high output, and long service life. It consists of a conical twin-screw extruder, a vacuum glue platform, a traction machine, a cutting and film coating machine, and a material mixing bracket.

f. The PVC profile machine adopts AC variable frequency controller or DC thyristor operation. The temperature control instrument is imported from abroad. In addition, the vacuum pump and traction engine of the auxiliary machine are high-quality products that are easy to maintain

g、 To match different molds, shaping platforms such as 4m, 6m, 8m, or 11m can be selected accordingly. The host adopts parallel twin-screw, which is particularly suitable for high-speed extrusion of various profiles.Comrise china top factory

GET A QUOTATION NOW