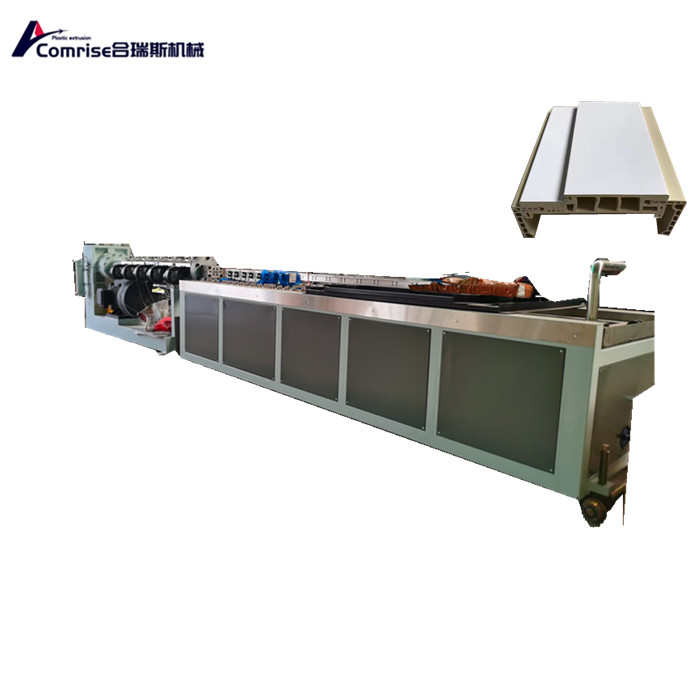

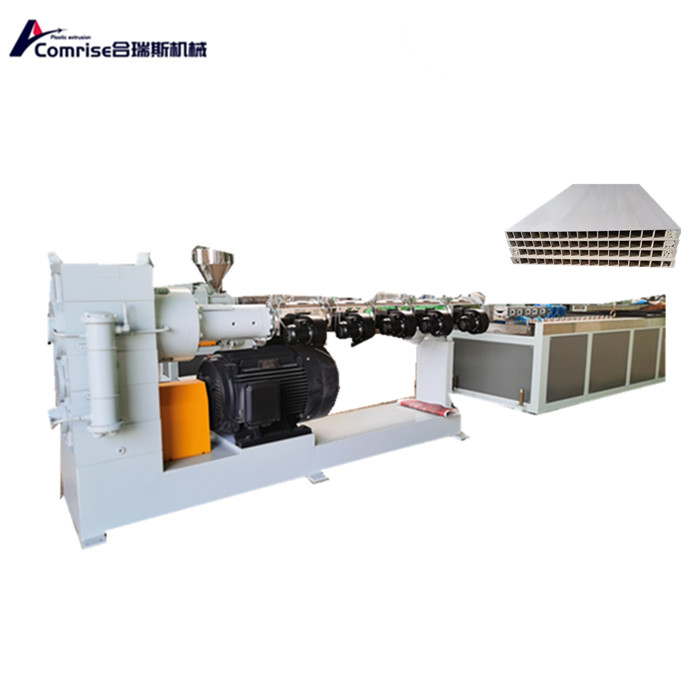

Door and Window Panel Profile Production Line

Send Inquiry

Comrise machinery factory Door and window panel profile production line is used for the manufacturing of PVC door panels, which has the advantages of stable production capacity and low energy consumption. Using internationally advanced CAD design software, 38crmoala alloy steel has superior quality and surface coating metal, special mixed material functions, and high capacity of screws and barrels.

The Door and Window Panel Profile Production Line screw core cooling system adopts a constant temperature system controlled by hot oil, which enables the material to be well plasticized; The material barrel adopts a vacuum exhaust type to fully evaporate moisture and maintain product quality.

The drive motor has the advantages of stable output and high torque, and also uses ABB or England Eurotherm speedors, which have the advantages of large extrusion capacity and high efficiency.

Our wide range of applications in production

1. Building decoration industry: building formwork panels, outdoor panels, indoor panels, residential panels, office panels, public building partitions, commercial decoration frames, cleanroom panels, etc.

2. Home decoration: bathroom ceiling panels, kitchen panels, furniture panels, home decor panels, various home shelves, etc.

3. Transportation industry: ships, airplanes, buses, trains, flooring, core layers, interior decorative panels, etc.

4. Industrial applications: Suitable for anti-corrosion projects such as chemical engineering, thermoforming, refrigeration warehouses, etc.

5. Other uses: building templates, sports equipment, aquaculture materials, seaside moisture-proof facilities, waterproof materials, artistic materials, and various light separation boards.

Line components

1. Twin screw extruder (SJSZ92/188)

2. Vacuum calibration tank

3. Towing machine

4. Cutting machine

5. Automatic stacker crane

7. Blenders, crushers, and blenders are also the options you truly need.

Advantages of Door and Window Panel Profile Production Line extruder

1. Double screw feeder.

2. ABB/Delta frequency converter, Siemens motor, Siemens contactor.

3. PLC control system is optional.

4. High quality gearbox, screws, and gun barrel.

5. Automatic feeder.

We have improved our manufacturing process and upgraded our technology. As a top machine manufacturing factory in China, we will strive to move forward

GET A QUOTATION NOW