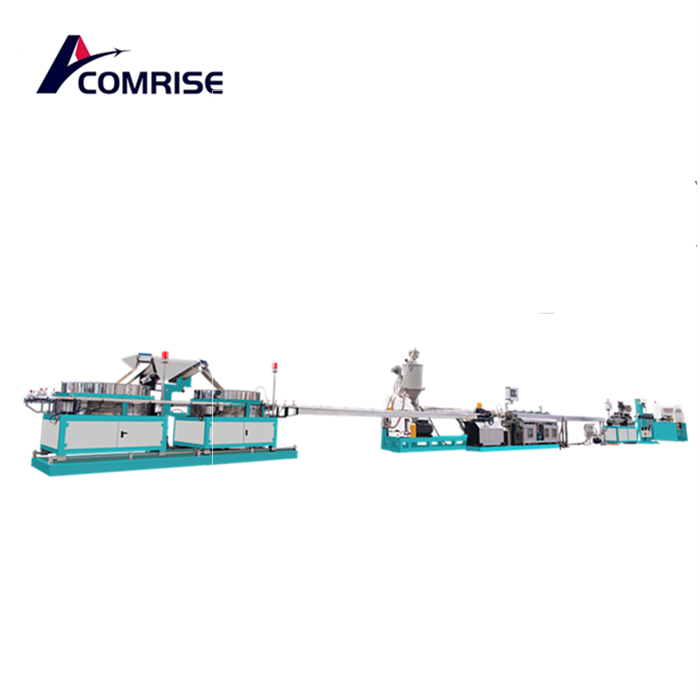

Drip Irrigation Pipe Machine

QINGDAO COMRISE MACHINERY CO.,LTD.

Our main product is plastic extrusion production line

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other countries.

Product Overview

Drip Irrigation Pipe Machine

characteristic:

1. The dropper is injection molded in one go and has a wide and long flow channel. It serves as a filter window and has strong anti clogging performance.

2. Good uniformity of water output. The drip head is directly welded to the drip irrigation pipe, reducing pressure loss and saving water.

3. It can achieve the simultaneous use of water and fertilizer, improve fertilizer utilization efficiency, save labor and fertilizer

4. Adopting a labyrinth flow channel with a certain pressure compensation effect.

5. The dropper is integrated with the pipeline, easy to install and use, low cost, and low investment.

6. Drip irrigation pipes of different specifications are suitable for different irrigation situations,

The distance between the dripper and can be adjusted according to the needs of different crops to meet different customers.

Application

This flat dripper irrigation tape production line is our new generation of high-speed thin-wall drip irrigation tape production line. Used for garden hose manufacturing machine,such products are widely used in crop (such cotton),fruit,vegetabies,trees,flowers and other industries of drip irrigation planting.

Main technical parameters

1.Drip head screening, conveying, embedding unit

The screening machine has a diameter of 1580mm and is compatible with both large and small pieces. Centrifugal pneumatic recognition, frequency conversion control. Recognition speed: Droplets<2500. Applicable droplet head size: 23mm * 6mm * 2.1mm, conveying speed>3000 pieces/minute

Can adapt to patch compatible lengths of 18MM-20-23-24-25-27-30

2.Single screw extruder SJ-90/Single screw extruder

(90) Screw, maximum extrusion capacity: 180kg/h.

It can adapt to raw material production and 90% recycled material production.

Motor: 75kw Huichuan servo or Guomao+Huichuan servo controller

Equipped with pressure transmitter, without color code machine.

A set of semi-automatic 160mm hydraulic screen changer

Gearbox: (Guomao or Jiangzi). Model (250).

3.Stainless steel vacuum sizing cooling water

Length 4 meters

Including dropper attachment sizing device

Including vacuum generation control system

Including pinhole and hole detection device

Including a broken pipe detection device

4.Stainless steel cooling water tank

Pipe diameter: φ16mm

Total length of sink: (6) meters

Stainless steel 304 material, adjustable height

5.Hauling machine

Double synchronous belt traction, pneumatic clamping

Panasonic servo motor control, motor power 3.0kw

Traction speed: 0-450m/min

6.Hole-punching machine

4 workstations for drilling holes

Punching machine power: 0.4kw Panasonic servo motor

Drilling speed:<4000 pieces/min

Supporting vacuum chip suction device

7.Dual station automatic winding machine

Automatic meter cutting for forming tube strips.

2.0KW * 2 servo motor brand: Panasonic

Maximum speed of 450 meters per minute

Next step is automatic

8.Automatic control system

Host: Huichuan servo or Guomao; Siemens PLC; Siemens touch screen; Schneider contactors and relays; Other servos: Panasonic brand.

Alarm functions for production line configuration: screen replacement pressure prompt, pinhole and hole detection, drip head shortage alarm, pipe breakage detection, drilling error alarm.

One click start function, automatic disconnection function, can achieve quick startup by one person, reducing waste.

Punching camera dual screen display.

9.Water chiller

About Us

Our Advantages

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

Drip Irrigation Pipe Machine Line

COMRISE High quality drip irrigation independent machinery Drip irrigation line we manufacture. comrise new production line has been launched, with better quality and faster speed. It can quickly replace droppers. Come in and take a look Standard output: Drip Irrigation Pipe Machine Line For each geometric shape of a given flat dropper, a kit can be used to replace the flat dropper output.china top factory machine supplier

Read MoreSend InquiryDrip Irrigation Pipe Production Line

COMRISE factory manufacturer drip irrigation pipe production line is our new generation of high-speed thin-wall drip irrigation tape production line. Used for garden hose manufacturing machine, such products are widely used in crop (such cotton), fruit, vegetabies, trees, flowers and other industries of drip irrigation planting.

Read MoreSend InquiryRound Drip Irrigation Pipe Making Machine

Comrise is a large plastic extruder manufacturer and supplier in China. We have been dedicated to researching plastic extrusion machinery for many years. Our products have a good price advantage and cover most of the Middle Eastern markets, such as Saudi Arabia, Kazakhstan, and so on. We look forward to becoming your long-term partner in China. Recently, our company has launched a new Round Drip Irrigation Pipe Making Machine

Read MoreSend InquiryDrip Irrigation Pipe Extrusion Production Line

Qingdao Comrise Machinery Is A China Professional Supplier For Pe Plastic Drip Irrigation Pipe Making Machinery For Agriculture And Round Drip Irrigation Hose Making Machine Drip Irrigation Pipe Production Line And Pe Water Rain Spray Tube Making Machine.Drip Irrigation Pipe Extrusion Production Line Comrise Has Own Advantages And New Technology On The Machines Innovation.

Read MoreSend InquiryInner Flat Emitter Type Drip Irrrigation Tape Making Machine

1. Using different or equivalent models of plastic extruders for synchronous extrusion, and using variable frequency speed control to control the extrusion amount, to ensure stable and reliable operation of the production process, flexible adjustment, and reduce energy consumption. Inner Flat Emitter Type Drip Irrrigation Tape Making Machine 2. The extruder screw and barrel are forged, quenched and tempered, and treated with 38CrMoAlA nitriding. Then, spray hard double alloy on the surface of the screw to improve its hardness and extend its service life. Meanwhile, the screw structure adopts a new type of structure, which is particularly suitable for PE recycled materials and has better plasticizing effect. 3. The double-layer composite drip irrigation tape forming mold adopts double-layer co extrusion hot runner center spiral feeding, cast aluminum air ring pre cooling, and uses far-infrared diameter measuring device (built-in air pump, no external air source required) for measurement, ensuring high film tube strength and uniform thickness. 4. Drip irrigation tape is formed using a separate vacuum forming device, ultimately meeting the standard specifications of drip irrigation tape. 5. After molding and air cooling, it enters the stainless steel water tank and undergoes circulating and shaping water cooling simultaneously. 6. Drip irrigation belt traction adopts drum type traction and variable frequency speed regulation, which is conducive to better and timely adjustment of production line operation. 7. The coiler adopts a three station center tension winding and is equipped with a far-infrared electronic counting device to ensure the accuracy of meter counting. At the same time, it is equipped with an automatic alarm device. When the set length is reached, it will automatically sound an alarm and replace the coil. 8. The entire production equipment adopts intelligent digital electrical control, which is easy to operate.

Read MoreSend Inquiry