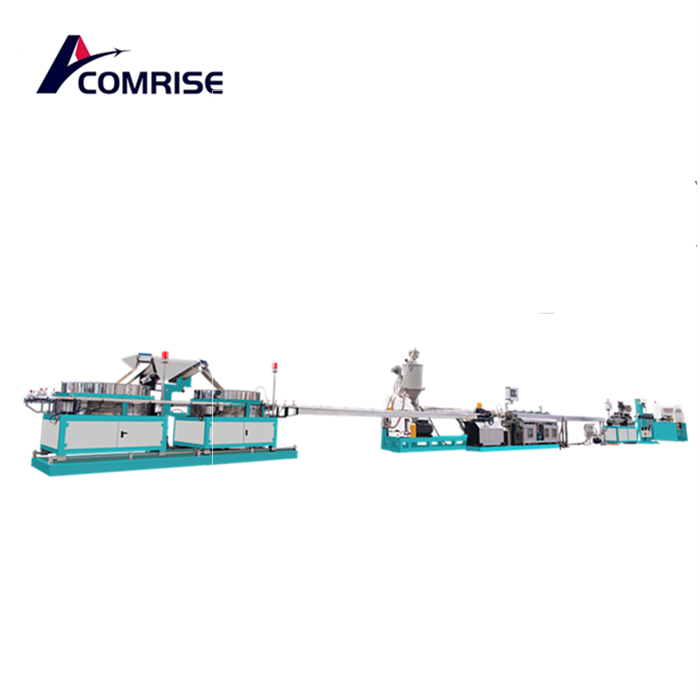

Round Drip Irrigation Pipe Making Machine

Send Inquiry

Round Drip Irrigation Pipe Making Machine 6mm/8mm/12mm/16mm/20mm

Round Drip Irrigation Pipe Making Machine Tube Making Line

Working Process of Plastic Round Drip Irrigation Pipe Production Line:

Dropper recognition, transportation and insert machine →Single screw extruder with Hopper dryer→(Co-extruder)→ Mould → Vacuum calibration cooling tank→ Haul -off machine→Automatic Drilling unit→ Coiler/Winder

Round Drip Irrigation Pipe Making Machine lists

NO

Machine Name

QTY

1

Dropper Recognition, Transportation and Insert machine

1SET

2

Single screw Extruder

1SET

3

Mould

1SET

4

Vacuum Calibrating Tank

1SET

5

Water Cooling Tank & Water Removing Equipment

1SET

6

Automatic Drilling Machine

1SET

7

Haul -off Unit

2SET

8

Winding Machine

1SET

9

PLC system & Electrical control cabinet

1SET

Features of Drip Irrigation Tube Extrusion Line:

-Production is stable and reliable.

-Transmitter transmission.

-The punch position is accurate.

-This kind of chip can be easily disassembled.

-Adopt PLC control, easy to operate.

-According to the production requirements, different specifications can be produced after changing the mould, conveying and stamping parts.

-Electrical components adopt domestic famous brands.

-The servo system USES imported components.

-Matched with instrument alarm device.

-It can also be used to make regular drip lines.

Final Product

(1) Drip irrigation tape is the core of drip irrigation system. It is suitable for planting crops in fields, greenhouses and greenhouses. It can save water and fertilizer and improve economic benefits.

(2) At present, drip irrigation is the most commonly used water-saving irrigation method in arid and water shortage areas. Drip irrigation technology can make water utilization rate reach 95%.

(3) Drip irrigation belt is widely used in the places lack of water. Water saving and grain increasing is an important measure to improve the yield of food crops, and drip irrigation technology plays an important role in food production.

(4) The working principle of drip irrigation technology is to use the low-pressure pipeline system to transport water directly to the field, and then through the emitter, orifice or drip irrigation belt installed on the capillary, the water drops evenly and slowly into the soil near the crop root zone, so that the soil in the most developed area of the crop root system often maintains the appropriate humidity and makes the soil water, fertilizer, gas, heat and microorganism live In order to create favorable conditions for high and stable yield of crops.

(5) The water for drip irrigation is stabilized, filtered and fertilized by the first filtration system, then passed through the main pipe and branch pipe, and finally dropped to the plant root through the drip irrigation belt. In a word, drip irrigation is suitable for crops in water shortage area.

GET A QUOTATION NOW