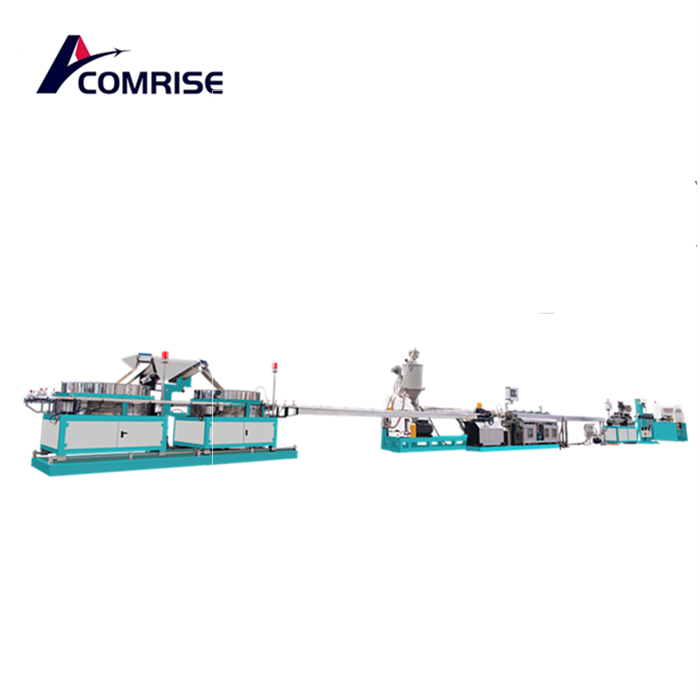

Inner Flat Emitter Type Drip Irrrigation Tape Making Machine

Send Inquiry

Inner Flat Emitter Type Drip Irrrigation Tape Making Machine

Product Description

1. Using different or equivalent models of plastic extruders for synchronous extrusion, and using variable frequency speed control to control the extrusion amount, to ensure stable and reliable operation of the production process, flexible adjustment, and reduce energy consumption.

2. The extruder screw and barrel are forged, quenched and tempered, and treated with 38CrMoAlA nitriding. Then, spray hard double alloy on the surface of the screw to improve its hardness and extend its service life. Meanwhile, the screw structure adopts a new type of structure, which is particularly suitable for PE recycled materials and has better plasticizing effect.

3. The double-layer composite drip irrigation tape forming mold adopts double-layer co extrusion hot runner center spiral feeding, cast aluminum air ring pre cooling, and uses far-infrared diameter measuring device (built-in air pump, no external air source required) for measurement, ensuring high film tube strength and uniform thickness.

4. Drip irrigation tape is formed using a separate vacuum forming device, ultimately meeting the standard specifications of drip irrigation tape.

5. After molding and air cooling, it enters the stainless steel water tank and undergoes circulating and shaping water cooling simultaneously.

6. Drip irrigation belt traction adopts drum type traction and variable frequency speed regulation, which is conducive to better and timely adjustment of production line operation.

7. The coiler adopts a three station center tension winding and is equipped with a far-infrared electronic counting device to ensure the accuracy of meter counting. At the same time, it is equipped with an automatic alarm device. When the set length is reached, it will automatically sound an alarm and replace the coil.

8. The entire production equipment adopts intelligent digital electrical control, which is easy to operate.

Product information

1. The dripper is a one-time injection molding, with wide and long flow channels, a built-in filter window, and strong anti-clogging performance. the

2. The uniformity of the water outlet is good, the dripper is directly welded to the inner wall of the drip irrigation pipe, the pressure loss is small, and water is saved.

3. It can realize the simultaneous application of water and fertilizer, improve the utilization rate of fertilizer, save labor and fertilizer.

4. The labyrinth flow channel is adopted, which has a certain pressure compensation effect.

5. The dripper and pipe belt are integrated, easy to install and use, low cost and less investment.

6. Drip irrigation pipes of different specifications are suitable for different irrigation situations, and the distance between drippers can be adjusted according to the needs of different crops to meet the needs of different customers.

GET A QUOTATION NOW