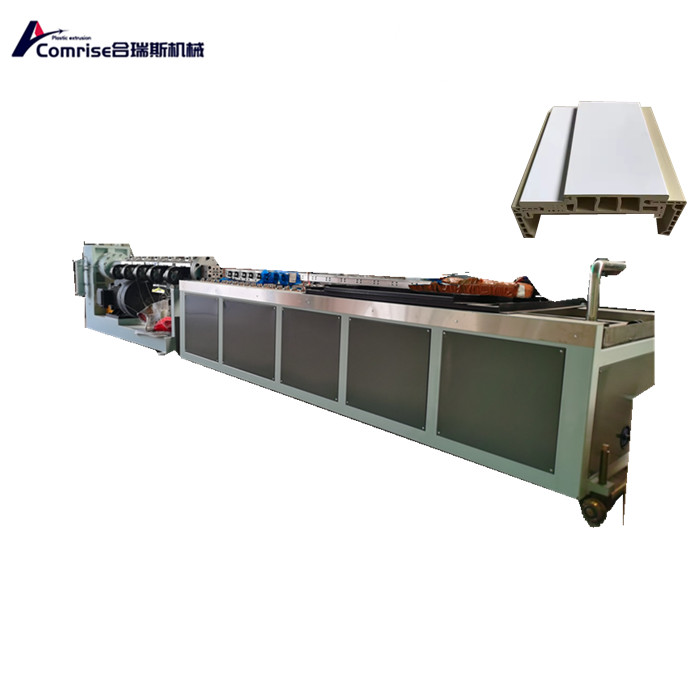

Door and window panel profile making machine

Send Inquiry

1. High precision production

Advanced extrusion technology can produce PVC profiles with accurate dimensions and stable quality.

2. Efficient operation

Comrise Door and window panel profile making machine can continuously extrude long PVC profiles at a stable speed.

3. Multifunctionality

These machines can produce PVC door and window profiles of various shapes and sizes. Just change the extrusion mold and some parameter settings.

4. Cost effectiveness

By precise control of the extrusion process, the waste of PVC material has been minimized to the greatest extent possible.

5. Good product quality

The extrusion process can evenly distribute additives and modifiers in PVC materials, enhancing the strength, hardness, and weather resistance of the profiles.

Extrusion technology

The core application technology of Comrise Door and window panel profile making machine is extrusion. It involves heating PVC resin particles to a molten state. This machine uses a powerful screw drive system to push molten PVC through the mold. The mold design has a specific cross-sectional shape for door or window profiles. For example, for casement window profiles, the shape of the mold includes the frame, window sash, and any grooves required for glass and hardware installation.

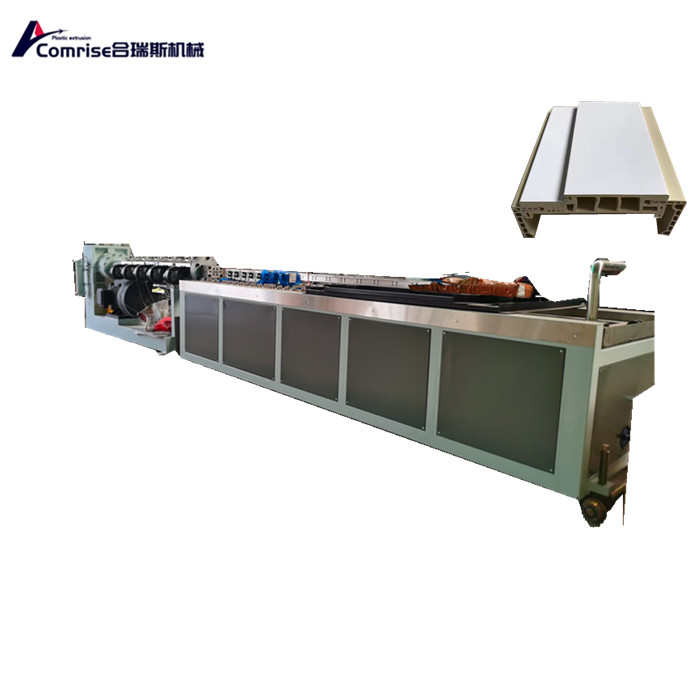

Vacuum calibration technology

After extrusion, use vacuum calibration to accurately cool and shape the profile. The extruded contour enters the vacuum calibration chamber. Vacuum helps to draw contours based on calibration tools, which have precise dimensions of the desired final product. This process eliminates any irregularities and ensures that the contour has a smooth surface and accurate dimensions.

By creating a vacuum environment, bubbles in the molten PVC are also removed, thereby improving the quality of the profile. The cooling water in the calibration system rapidly cools the profile, allowing the PVC to solidify and maintain its shape when leaving the chamber.

Cutting technology

Automatic cutting technology is an important component of machine operation. After the contour is compressed and calibrated, it needs to be cut into appropriate lengths. The cutting mechanism can be programmed to cut specific lengths of profiles according to the requirements of the door and window manufacturing process.

Some advanced Comrise Door and window panel profile making machine use high-speed saw blades or laser cutting technology. Laser cutting can provide more precise cutting and smooth edges, thereby reducing the need for further precision machining of the cutting end. The cutting process is synchronized with the extrusion speed to ensure continuous and efficient production.

Residential building applications

Comrise Door and window panel profile making machine is widely used in the production of residential building profiles. They can produce various profiles for different types of doors and windows, such as casement windows, sliding doors, and French doors. These profiles are used to manufacture lightweight, durable, and well insulated frames. For example, energy-saving window profiles help reduce heat transfer between inside and outside the house, thereby saving energy costs for heating and cooling.

Profile

Commercial building applications

In commercial buildings such as offices, shopping centers, and hotels, these machines are used to produce large door and window profiles. The produced profiles can be used to manufacture large glass doors and windows, providing good natural light penetration and beautiful appearance. Machine manufactured PVC profiles can also meet the requirements of fire resistance and sound insulation standards in commercial environments. For example, in noisy urban areas, soundproof PVC window profiles can reduce noise from the streets and create a more comfortable indoor environment.