China Hdpe Pipe Manufacturing Machine Trade Manufacturer, Supplier, Factory

Each individual member from our large performance revenue crew values customers' requirements and organization communication for Hdpe Pipe Manufacturing Machine Trade,Hdpe Pipe Coiler Machine 110mm,16 Mm Hdpe Pipe Machine,Hdpe Pipe 3 Inch Machine,Pe Hdpe Water Pipe Machine, Trust us and you will gain a lot more. You should truly feel totally free to make contact with us for additional data, we assure you of our greatest notice at all times.

Hdpe Pipe Manufacturing Machine Trade, Due to our good goods and services, we've received good reputation and credibility from local and international customers. If you will need more information and are interested in any of our solutions, be sure to feel free to contact us. We look forward to becoming your supplier in the near future.

Hot Products

Inner Flat Emitter Type Drip Irrrigation Tape Making Machine

1. Using different or equivalent models of plastic extruders for synchronous extrusion, and using variable frequency speed control to control the extrusion amount, to ensure stable and reliable operation of the production process, flexible adjustment, and reduce energy consumption. Inner Flat Emitter Type Drip Irrrigation Tape Making Machine 2. The extruder screw and barrel are forged, quenched and tempered, and treated with 38CrMoAlA nitriding. Then, spray hard double alloy on the surface of the screw to improve its hardness and extend its service life. Meanwhile, the screw structure adopts a new type of structure, which is particularly suitable for PE recycled materials and has better plasticizing effect. 3. The double-layer composite drip irrigation tape forming mold adopts double-layer co extrusion hot runner center spiral feeding, cast aluminum air ring pre cooling, and uses far-infrared diameter measuring device (built-in air pump, no external air source required) for measurement, ensuring high film tube strength and uniform thickness. 4. Drip irrigation tape is formed using a separate vacuum forming device, ultimately meeting the standard specifications of drip irrigation tape. 5. After molding and air cooling, it enters the stainless steel water tank and undergoes circulating and shaping water cooling simultaneously. 6. Drip irrigation belt traction adopts drum type traction and variable frequency speed regulation, which is conducive to better and timely adjustment of production line operation. 7. The coiler adopts a three station center tension winding and is equipped with a far-infrared electronic counting device to ensure the accuracy of meter counting. At the same time, it is equipped with an automatic alarm device. When the set length is reached, it will automatically sound an alarm and replace the coil. 8. The entire production equipment adopts intelligent digital electrical control, which is easy to operate.Pipe Machine

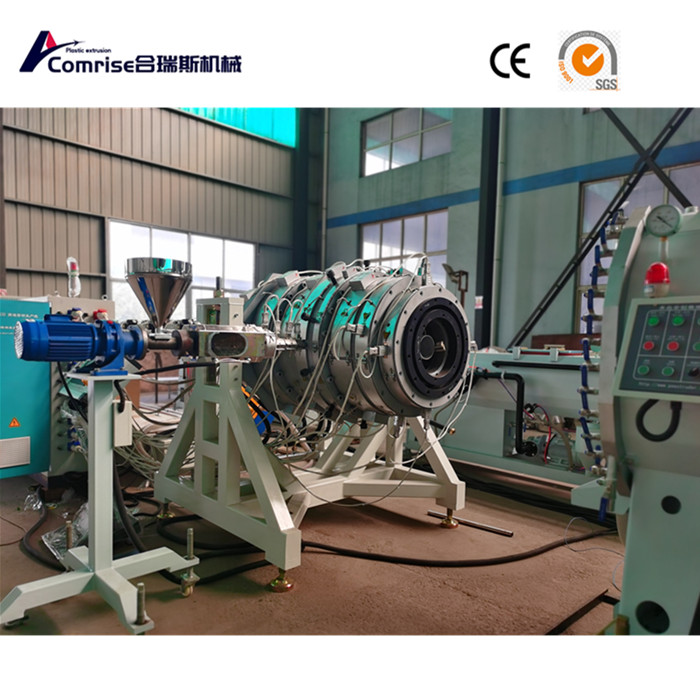

Comrise Machinery is a leading Chinese manufacturer specializing in plastic Pipe Machine extrusion equipments and Pipe Machine production lines, with extensive industry experience and technical expertise. Comrise are committed to providing global customers with high-quality, high-performance solutions for plastic pipe production, catering to a wide range of applications.50-160mm Pe Pipe Machine

China Comrise's 50-160mm Pe Pipe Machine is the ultimate pe pipe production machine for any business. Its efficiency, speed, ease of maintenance, and stable running process make it a game-changer in the production of pe pipes. Invest in 50-160mm high efficiency Pe Pipe Machine today and take your business to the next level.Hdpe Pe Pipe Making Machine

China Comrise is a professional manufacture for advanced hdpe pe pipe making machine. With have 20 more years experience in the plastic extrusion machinery field and own R&D team, experienced international sales team, patient and on time service team, their product are well known by customers home and abroad.Corrugated Pipe Extruder

Comrise high quality Corrugated Pipe Extruder is a specialized industrial machine used in the manufacturing of corrugated plastic corrugated pipes. These Corrugated Pipe Extruder is widely used in various applications such as drainage systems, electrical conduits, telecommunications due to their flexibility, durability, and lightweight properties.PVC Pipe Production Line machine

Comrise PVC pipe extrusion line includes conical twin screw extruder, spiral die head, vacuum tank, water tank, haul-off, no-dust cutter or planetary cutter, belling machine with O-ring sockets or rectangular sockets or U types of sockets.this machine supplier Our PVC pipe production line machine can make pipes ranging from 16-630mm PVC Pipe Machine, wall thickness range of 1-30mm.