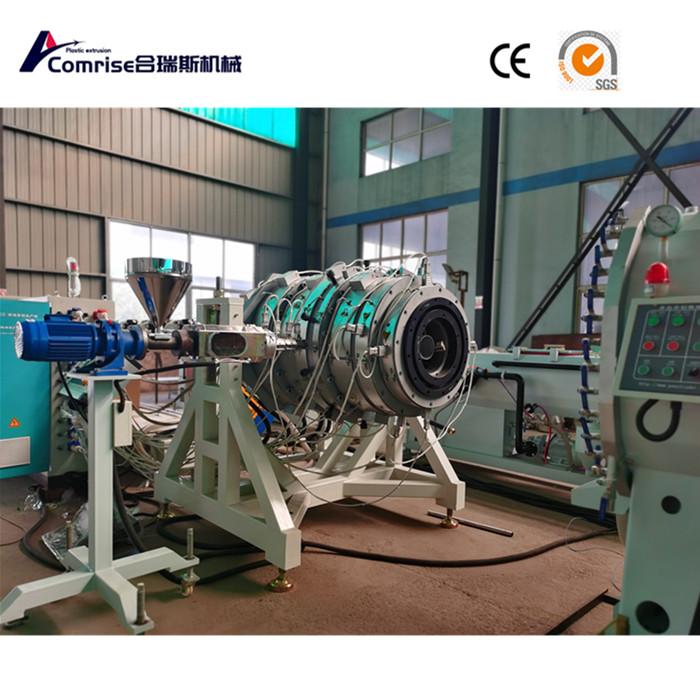

630-1200mm HDPE pipe production line is under produce

2025-05-27

Our company is producing a 630-1200mm HDPE pipe extrusion production line, ABA three-layer co extrusion, equipped with PLC and meter weight controller

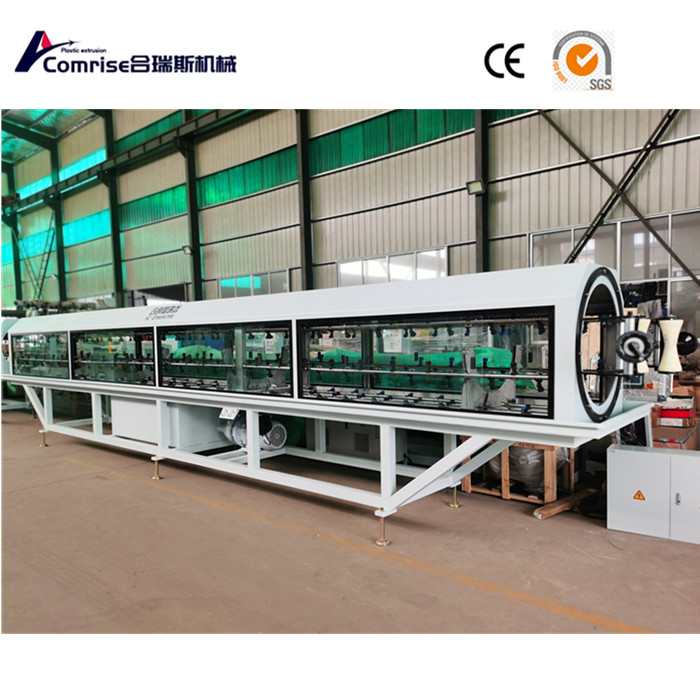

The PE series plastic pipe production line is mainly used for the production of agricultural and building drainage and sewage. The unit consists of a vacuum sizing box, a traction machine, a cutting machine, a flipping rack, etc. The single screw extruder and traction machine adopt imported AC variable frequency speed regulation devices, and the vacuum pump and traction motor are all good products.

You can choose chip free cutting, saw blade cutting or planetary cutting, and the unit has reliable performance and high production efficiency. Our company can produce inner wall spiral pipes, inner wall hollow pipes, and core foam pipes according to user requirements by equipping dedicated equipment and replacing extruders. We can also produce pipes made of other materials such as PP, PE, PPR, HDPE, etc. The planetary cutting machine adopts fully automatic computer numerical control, which has the advantages of easy operation and reliable performance.

By using a low-temperature and low-pressure extrusion system, the plasticizing effect and extrusion capacity of the product can be improved, resulting in a 10-15% year-on-year increase in production.

PE/HDPE Pipe Extrusion Line

This series of pipe machine is mainly used for producing drainage pipe, agricultural irrigation pipe, gas pipe, water supplying pipe, cable conduit pipe and etc.

This pipe has some excellent features such as heating and aging resistant, high mechanical strength, environmental stress cracks resistant, good creep resistant and etc. our extrusion line is designed with high efficiency extruder and equipped with reducer which is high speed and low noise.

Process Flow

Raw material(Recycled or New material)+ Master Batches → Mixing → Vacuum Feeder →Plastic Hopper Drier→ Single screw extruder →Co-extruder for color string & Multi Layers → Mould → Vacuum Calibration Tank → Spray Cooling Tank → Haul-off machine→ None Dust Cutting Machine→ Stacker → Final Product

The PE series plastic pipe production line is mainly used for the production of agricultural and building drainage and sewage. The unit consists of a vacuum sizing box, a traction machine, a cutting machine, a flipping rack, etc. The single screw extruder and traction machine are equipped with imported AC variable frequency speed regulation devices, and the vacuum pump and traction motor are made of high-quality products.

You can choose chip free cutting, saw blade cutting or planetary cutting, and the unit has reliable performance and high production efficiency. Our company can produce inner wall spiral pipes, inner wall hollow pipes, and core foam pipes according to user requirements by equipping dedicated equipment and replacing extruders. We can also produce pipes made of other materials such as PP, PE, PPR, HDPE, etc. The planetary cutting machine adopts fully automatic computer numerical control, which has the advantages of easy operation and reliable performance.

By using a low-temperature low-pressure extrusion system, the plasticizing effect and extrusion capacity of the product can be improved, resulting in a 10-15% increase in production compared to the same period last year