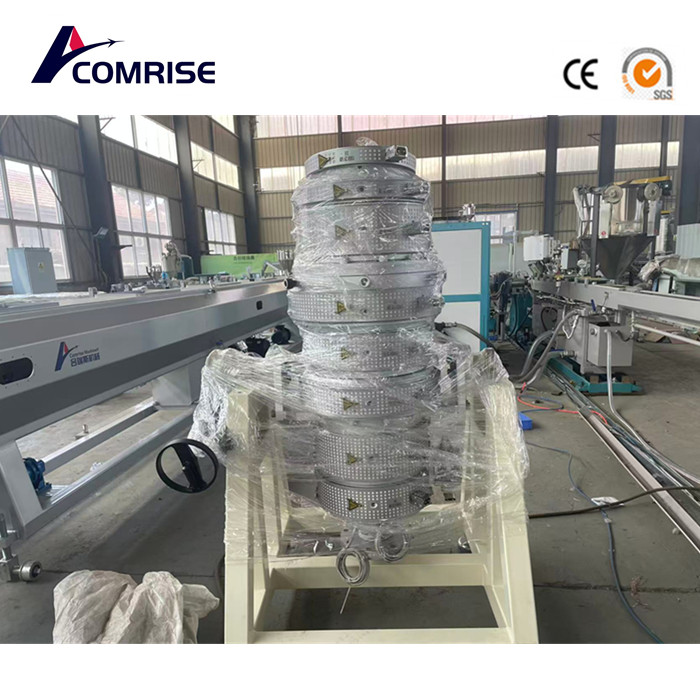

63-250mm HDPE pipe production line ready for shipment

2025-05-29

63-250mm HDPE pipe production line ready for shipment

75-250mm PE Pipe Extrusion machine is mainly used for producing agricultural irrigation pipe, gas supplying pipe, water supplying pipe, cable protection pipe etc. The pipe has some excellent features such as low temperature impact resistance, reliable connection, good stress crack resistance, good chemical resistance, good wear resistance, long using life, etc. our extrusion line is designed with high efficiency extruder and equipped with reducer which is high speed and low noise, Gravimetric dosing unit and ultrasonic thickness indicator can be assembled according to customer's demand to ascend the precise of the pipes . Turn key solution can be provided, like laser printer crusher, shredder, water chiller, air compressor etc. to achieve high-grade and automatic tube production.

Process Flow:

Raw material+ Master Batches → Mixing → Vacuum Feeder →Plastic Hopper Drier→ Single Screw Extruder →Co-extruder for color string &Multi Layers → Mould → Vacuum Calibration Tank → Spray Cooling Water Tank → Haul-off → No Dust Cutter → Single Winder or Stacker →Final Product Inspecting &Packing

host system

Screw design: Adopting single screw or twin screw configuration (screw diameter 50-75mm), optimizing the groove depth and compression ratio for different materials. For example, PVC processing commonly uses conical twin-screw, while PE/PP is suitable for parallel twin-screw.

Temperature control module: zone heating (barrel divided into 4-6 sections) combined with air cooling system, temperature control accuracy reaches ± 1 ℃, avoiding material degradation. For example, the processing temperature range for PVC is 160-190 ℃, while for PE it is 180-220 ℃.

Drive system: equipped with variable frequency motor or servo motor, with extrusion speed fluctuation rate ≤ 1%, suitable for high-speed extrusion requirements (such as corrugated pipe production line speed up to 30m/min).

Mold and runner optimization

Multi cavity mold technology: support efficient production modes such as "the first mock examination with four outlets", reduce equipment investment costs, and apply to the mass manufacturing of φ 16-200mm wire pipes and water supply pipes.

Composite co extrusion head: can stack different materials (such as PPR+fiberglass reinforcement layer) or colors to meet the needs of functional pipes.

Cooling and shaping system

Vacuum Spray Box: Made of SUS304 stainless steel material, with a vacuum degree of -0.08~-0.1MPa, and equipped with multi-stage water cooling modules to accurately control the roundness of the pipes (tolerance ± 0.1mm).

Three dimensional adjustment device: supports height and horizontal fine-tuning, suitable for the shaping requirements of complex shaped pipes.

Traction and cutting system

Multi mode tractor: Wheel traction is suitable for flexible hoses, track traction (traction force up to 8kN) is suitable for hard pipes, and speed synchronization error is ≤ 0.1%.

Intelligent cutting device: Circular saw blade cutting machine (accuracy ± 0.5mm) is used for small-diameter pipes, and planetary cutting machine (accuracy ± 1mm) is suitable for large-diameter pipes.