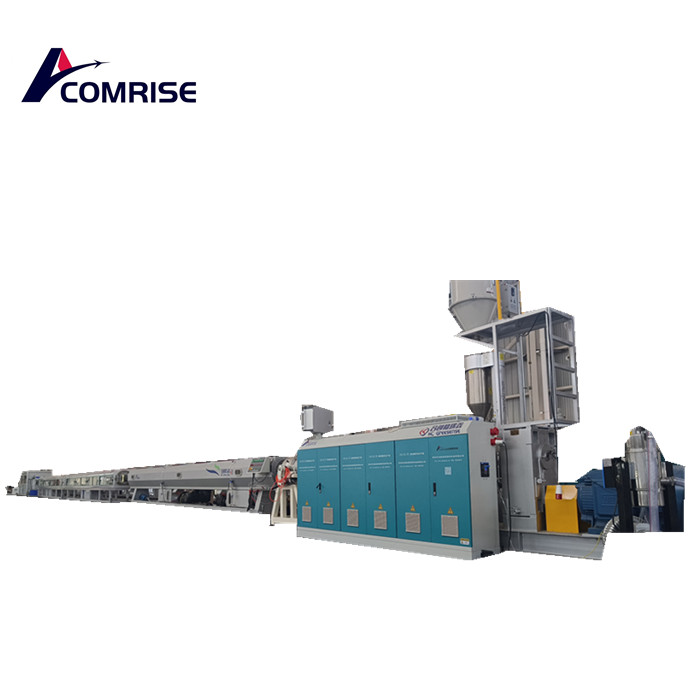

China 110mm HDPE Pipe production line Manufacturer, Supplier, Factory

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for 110mm HDPE Pipe production line,HDPE 20-110mm Pipe Extrusion Line,20mm-110mm HDPE Pipe Extrusion Production Line,20-110mm HDPE/PPRC pipe extrusion line machine,hdpe pe pipe production line plant, Our goods are strictly inspected before exporting , So we gain a excellent standing all around the planet. We wanting ahead to cooperation with you in the foreseeable future.

110mm HDPE Pipe production line, Make sure you really feel free to send us your requirements and we'll respond to you asap. We now have got a qualified engineering group to serve for your just about every in depth needs. Cost-free samples could be sent for yourself personally to understand much more information. In an effort to meet your requires, remember to actually feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

Hot Products

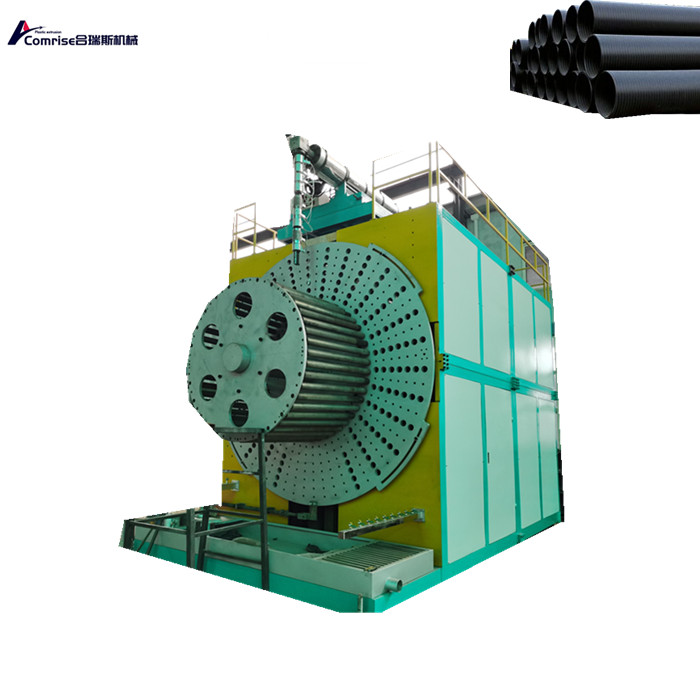

HDPE Large-Diameter Hollowness Wall Winding Pipe Machine

COMRISE High quality HDPE large-diameter hollowness wall winding pipe machine supplierr is offered by China manufacturer Comrise, which can produce pipe size range from Ø200-3000mm. We are one of the drafters of nation standard for hollow wall winding pipe. PE hollow wall winding pipe is mainly used for water drainage, same as double wall corrugated pipe. Compared with double wall corrugated pipe, it have advantages of low machine investment cost and larger pipe diameter. With different design of profile tube our machinery can produce pipes of different ring stiffness that adapt to different conditions and fields.PP Hollow Formwork Board Machine

Qingdao Comrise Machinery is a professional manufacturer of pp hollow formwork board machine that can provide you with high-quality and stable pp hollow formwork board machine Machines with different specifications. Our machines are designed with mature technology and experience sale team and production team.PVC Pipe Extrusion Production Line

Comrise factory PVC pipe extrusion production line was developed by our company using advanced technology from Western Europe. The host is a SJSZ55/120 or SJSZ65/132 conical twin-screw extruder equipped with dual tube single control stainless steel spray calibration. When adjusting one tube while the other tube is affected, it avoids waste situations. The combination of automatic single control double wire drawing machine and slicing machine with front double calibration technology makes the operation more flexible, allowing you to enjoy the economic benefits brought by separate control double tube extrusi16mm-63mm Pe Pipe Machine

With over 20 years of experience in the plastic extrusion machinery sector, China Comrise has honed its expertise in the field of 16mm-63mm pe pipe machine. This experience has been instrumental in making the company one of the best in the market. In this article, we will delve into why China Comrise is considered one of the best 16mm-63mm pe pipe machine manufacturers in the market.Spiral Tube Winding Machine

COMRISE is a professional company that specializes in providing spiral tube winding machine for underground sewage construction or building usage. Comrise offer a range of machines that can create different types of pipes, each with its unique advantages. Comrise team of experts can work with customers to find the perfect solution for their needs, and they pride themselves on our customer service. With COMRISE, you can be sure that you are getting the best quality products and services available for the spiral tube winding machines.Inner Flat Emitter Type Drip Irrrigation Tape Making Machine

1. Using different or equivalent models of plastic extruders for synchronous extrusion, and using variable frequency speed control to control the extrusion amount, to ensure stable and reliable operation of the production process, flexible adjustment, and reduce energy consumption. Inner Flat Emitter Type Drip Irrrigation Tape Making Machine 2. The extruder screw and barrel are forged, quenched and tempered, and treated with 38CrMoAlA nitriding. Then, spray hard double alloy on the surface of the screw to improve its hardness and extend its service life. Meanwhile, the screw structure adopts a new type of structure, which is particularly suitable for PE recycled materials and has better plasticizing effect. 3. The double-layer composite drip irrigation tape forming mold adopts double-layer co extrusion hot runner center spiral feeding, cast aluminum air ring pre cooling, and uses far-infrared diameter measuring device (built-in air pump, no external air source required) for measurement, ensuring high film tube strength and uniform thickness. 4. Drip irrigation tape is formed using a separate vacuum forming device, ultimately meeting the standard specifications of drip irrigation tape. 5. After molding and air cooling, it enters the stainless steel water tank and undergoes circulating and shaping water cooling simultaneously. 6. Drip irrigation belt traction adopts drum type traction and variable frequency speed regulation, which is conducive to better and timely adjustment of production line operation. 7. The coiler adopts a three station center tension winding and is equipped with a far-infrared electronic counting device to ensure the accuracy of meter counting. At the same time, it is equipped with an automatic alarm device. When the set length is reached, it will automatically sound an alarm and replace the coil. 8. The entire production equipment adopts intelligent digital electrical control, which is easy to operate.