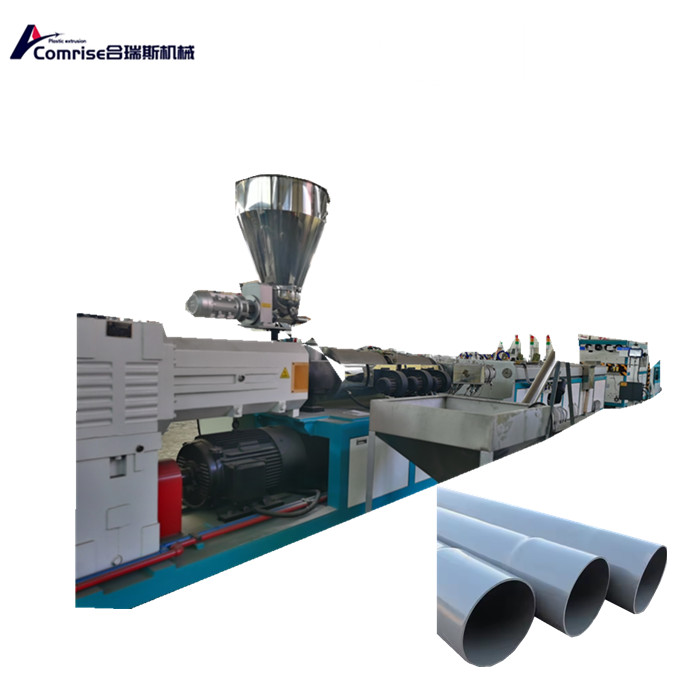

PVC Pipe Extrusion Production Line

Send Inquiry

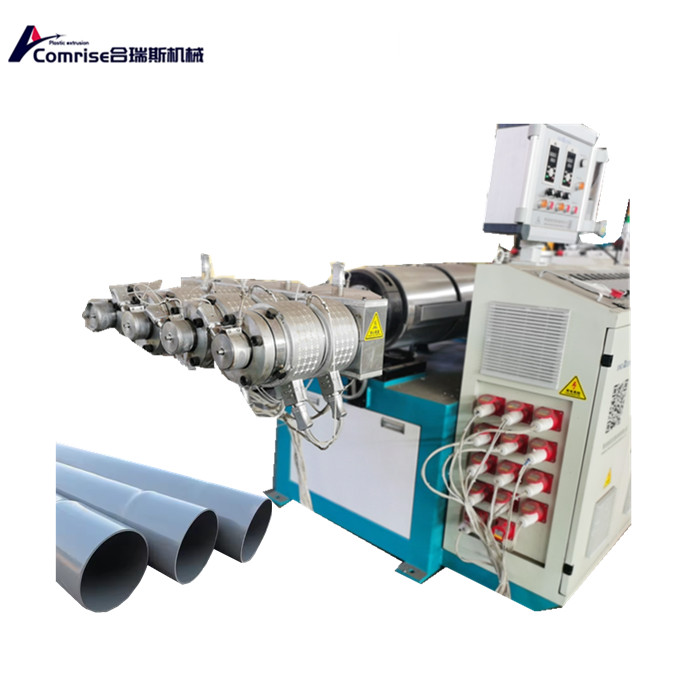

1. Ensure long-term stable operation and long service life

2. Compact structure, low noise, high load-bearing capacity, high transmission efficiency, ensuring long-term stable operation

3. Heating is controlled by solid-state relays (S.S.R) to achieve stable heating; (SSR) No sparks or noise, improving safety production.

4. The Siemens PLC control system has reliable technology, automatic and intelligent functions, which are used for centralized control and monitoring of extrusion production lines, acilitating easy operation.

The standard pvc pipe extruder includes: feeder, SJSZ series conical twin screw extruder, extrusion die, vacuum calibration tank, spray cooling tank (for large pipes), tractor, laser printer (optional), cutter, stacker or automatic opening machine. We also provide auxiliary machines such as raw material mixers, crushers, crushers, air compressors, and chillers. Our company has a comprehensive PVC Pipe Extrusion Production Line, including four chamber pipe extrusion production line, double chamber pipe extrusion production line, and large-diameter pipe extrusion production line. Our company will also provide basic formulas for PVC pipe production, and customers can easily adjust according to the formulas. We manufacture machines for producing different types of PVC pipes, including PVC and PVC pipes. Our PVC pipe extrusion production line can range from a minimum size of 16mm to 800mm for single or multiple layers.

Plastic PVC pipe making machine - PVC water pipe/PVC conduit/PVC drainage pipe

PVC conduit diameter: 16mm, 20mm, 25mm, and 32mm

PVC water pipe diameter we can manufacture: 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, 75mm, 90mm, 110mm, 125mm, 160mm, 200mm, 225mm, 250mm, 280mm, 315mm, 355mm, 400mm, 450mm, 500mm, 630mm

PVC drainage pipe diameter we can manufacture: 50mm, 63mm, 75mm, 90mm, 110mm, 160mm, 200mm

This device is mainly used to produce plastic PVC pipes of various diameters and wall thicknesses, for agricultural water supply and drainage, building water supply and drainage, cable laying, and other applications. The device consists of a conical twin-screw extruder, a vacuum shaping table, a traction machine, a cutting machine, a stacking rack, etc. The screw extruder and traction machine adopt AC variable frequency speed regulation device, and the vacuum pump and traction motor adopt branded products.

Raw material mixing forPVC Pipe Extrusion Production Line: It involves adding PVC stabilizers, plasticizers, and other auxiliary materials to the high-speed mixer in proportion and order according to the process. Heat the material to the set process temperature through self friction between the material and the machinery, and then cool it to 40-50 ° C through a cold mixer; In this way, it can be added to the hopper of the extruder

GET A QUOTATION NOW