High Configuration and High-speed 20-110mm HDPE Pipe Machine

Send Inquiry

HDPE PIEP

Good hygiene performance: During the processing of PE pipes, no heavy metal salt stabilizers are added, the material is non-toxic, there is no scaling layer, and there is no bacterial growth, which solves the hidden danger of secondary pollution of urban drinking water.

Excellent corrosion resistance: except for a few strong oxidants, it can withstand corrosion from various chemical media; No electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years at rated temperature and pressure.

Better impact resistance: PE pipes have good toughness, high impact resistance, and can withstand heavy objects directly passing through the pipeline will not cause the pipeline to rupture.

This machine is the highest configuration of the high-speed HDPE pipe production line, equipped with a PLC control system, Siemens brand electrical components, WEG motor, and high-end meter weight control system WALTHMAC. The production speed can reach 28m/min, which is very fast. Due to the meter weight of WALTHMAC, it can save materials to the maximum extent, ensure uniform wall thickness of the pipe, and achieve high-quality and high-speed production.

(1)ExtruderFunction:

The extruder is responsible for melting and extruding the polyethylene pellets into a continuous tube.

Features: High torque drive system, precision temperature control, and efficient screw design for optimal material

processing.

Longth ratio L / D :38:1Material quality: 38CrMoAlA

Siemens motor:90kw

ABB inverter

Siemens PLC computer control panel

(2)New technology die head

The extrusion die adopts spriral structure to ensure uniform melt temperature, completely eliminate weld lines, overcome the stripe defect caused by blue die, and produce pipe products with smooth inner and outer walls and good compactness. Pressure grades: as to customer table

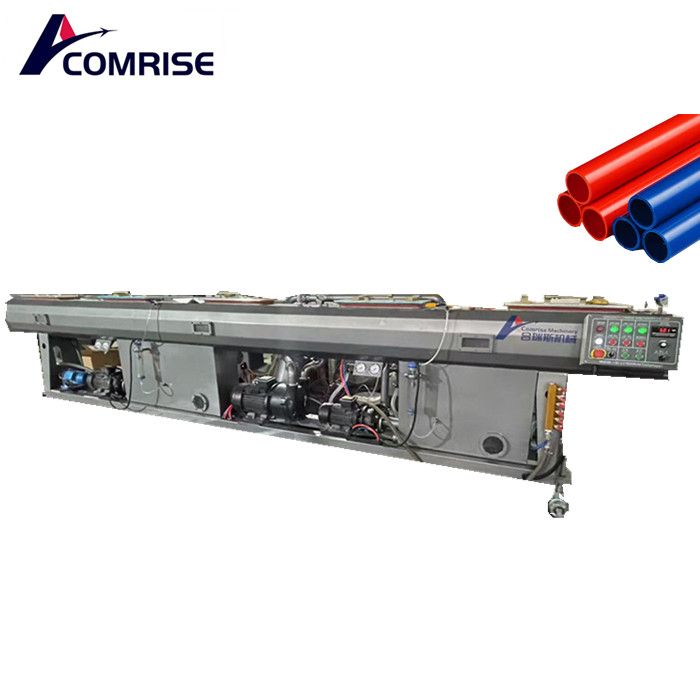

(3)Vacuum sizing water tankFunction: The cooling system rapidly cools the extruded pipe to maintain its shape and structural integrity.

Features: Multi-stage cooling tanks with adjustable water flow rates and temperature control to ensure consistent cooling.vacuum pump:3 + 4 KW, 2 sets

Water pump: 3 + 4 KW, 2 sets

Tank material: 100% Stainless steel

Length: 6000 mm

(4)Spray water tankWater pump : 4 KW * 1 setWater tank material:stainless steel

Length : 6000mm

Over all size :6500×500×1300mm

(5)Halling off machine:

The traction device is designed to be able to pull the pipe in a continuous and stable state. Its compact structure, maintenance-free structure and absolute balance of operation are its outstanding features.Clamping way:claw pneumaticTraction speed:1-15m/minPulling motor:motor 1.5KW x 2Mode of speed regulation:Frequency Control

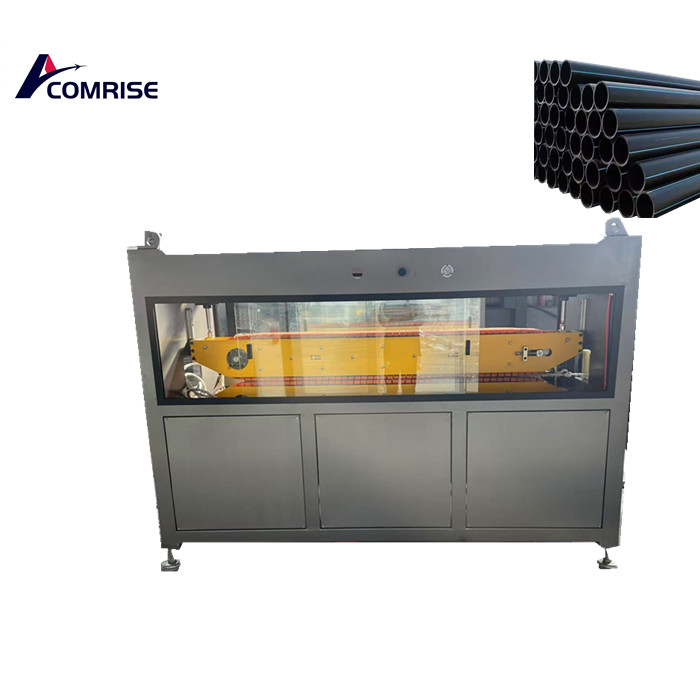

(6)Cutting machine:

Cutting method:Rotary cutting with circular bladeclamping way:Pneumatic clamp

Worktable movement way: Synchronous follow up, pneumatic reset

Revolution motor power:1.5KW

Method of electric control : Independent setting of high-speed counter and PLC linkage

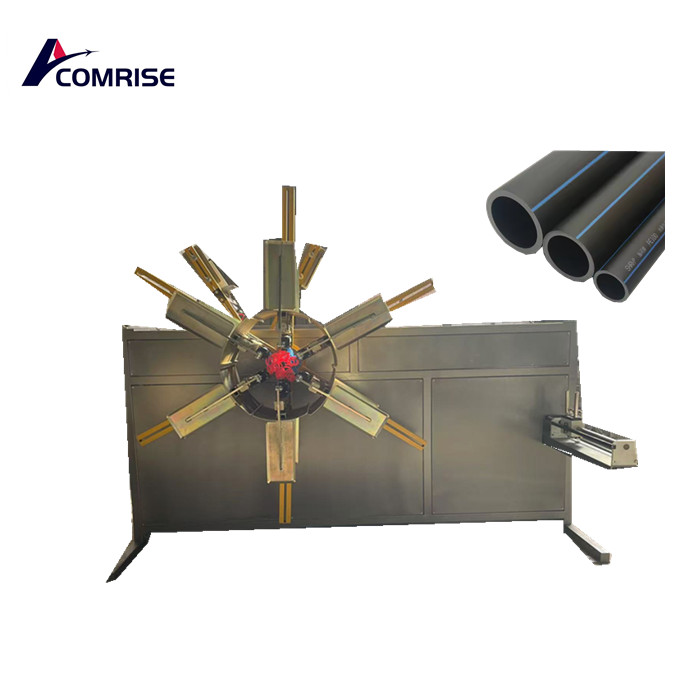

The winding machine is used for small-sized 20-63mm PP PE PPR HDPE LDPE pipes. High winding efficiency

Welcome to inquire

GET A QUOTATION NOW