China Plastic Production Line for Pipe Manufacturer, Supplier, Factory

The key to our success is "Good Products Good quality, Reasonable Price and Efficient Service" for Plastic Production Line for Pipe,Production Line for Plastic Pipe,Used Plastic Pipe Production Line,Plastic Corrugated Pipe Production Line,16 63mm Plastic Pipe Extrusion Production Line, In order to expand our international market, we mainly supply our oversea customers Top quality performance products and service.

Plastic Production Line for Pipe, With more and more Chinese solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We've enough confidence to provide you both better items and service, because we have been more and more powerful, professional and experience in domestic and international.

Hot Products

HDPE Pipe High-Speed Extrusion Production Line

Due to its unique advantages, 20mm-110mm HDPE Pipe High-Speed Extrusion Production Line is widely used in building water supply, building drainage, buried drainage pipes, building heating, gas pipelines, electrical and telecommunications protection sleeves, industrial pipes, agricultural pipes, etc. It is mainly used in urban water supply, urban gas supply, and farmland irrigation.

Our HDPE high-speed extrusion production line has established effective long-term cooperation with countries such as India and PakistanDouble Wall Corrugated Pipe Production Line

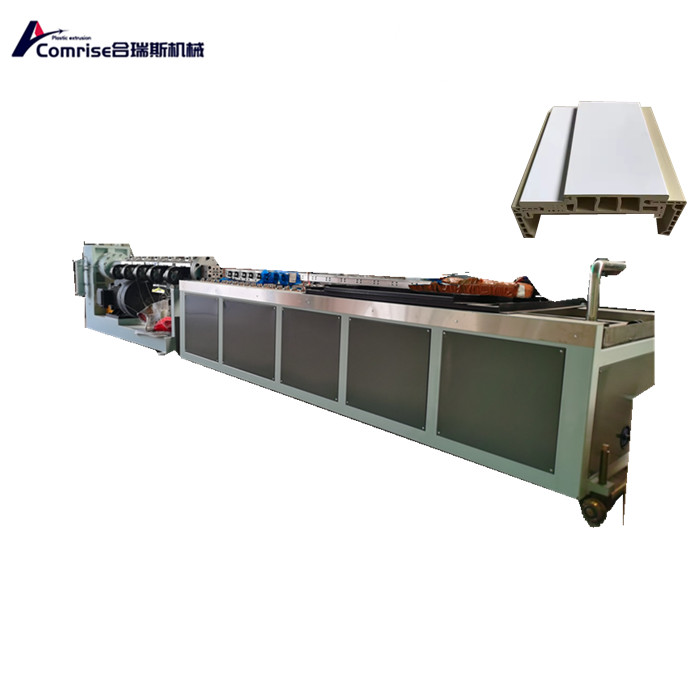

Comrise machinery is a professional supplier for Double Wall Corrugated Pipe Production Line together with pre-stressed plastic corrugated pipe machine, power pipe machine, single wall corrugated pipe machine, automotive wire harness corrugated pipe machine, PPR/PE/PVC/PERT pipe machine, and various other plastic pipe machines, plastic profile machines, and plastic board machines. Comrise machinery has strong technical strength, strong development capabilities, and advanced production processes. Based on the development of new materials and new processes, it produces various plastic extrusion lines. Comrise company's products are distributed throughout the country and are exported to many countries such as Europe, South America, Middle East, Southeast Asia, Oceania,and Africa.Spiral Duct Manufacturing Machine

As a professional provider of larger diameter spiral duct manufacturing machines, COMRISE is committed to providing our customers with the best quality machinery possible. Whether it's underground sewage construction or building usage, our machines are tailor-made for every customer's unique needs. At COMRISE, we believe in providing our customers with the best quality products and services, and we are dedicated to achieving this goal with every machine we make.Plastic Thick Board Production Line

Characteristics of PP, PE, ABS, PVC thick board production line: products manufactured by PP, PE board production line features with impact resistance, corrosion resistance, high temperature resistance, non-toxic and tasteless, smooth surface appearance, low density, light weight, easy processing, good size stability, rigidity, good heat resistance, no poisonous gas released during welding.Plastic Thick Board Production LineHigh Efficiency PVC Pipe Production Line

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line,High Efficiency PVC Pipe Production Line, PE large-diameter hollow-wall winding pipe production line, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line , the plastic coated corrugated pipe production line,PE black jacket insulation pipe production line and PE sheet/board production line, . HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.Air Conditioner Pipe Insulation Machine

Comrise machines are designed for durability, efficiency, and productivity. Comrise as a China Supplier for air conditioner pipe insulation machine and solar insulation pipe machine are equipped with advanced technology that allows for prefect welding of pipes. The air conditioner pipe insulation machine is perfect for insulating pipes that need to maintain the temperature of their contents, while the PVC pipe machine is ideal for plumbing and irrigation systems.