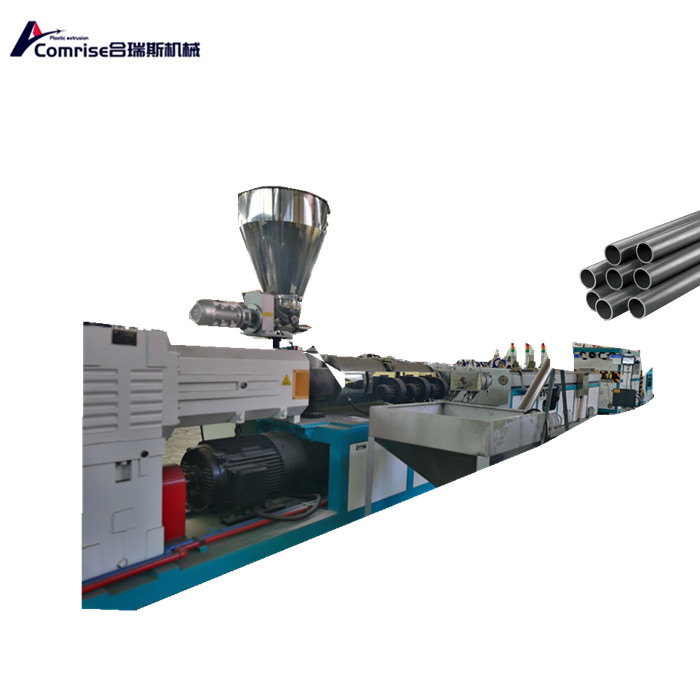

High Efficiency PVC Pipe Production Line

Send Inquiry

1.PVC pipe machine is mainly used to manufacture plastic PVC pipes of various diameters and wall thicknesses, such as agricultural and construction pipelines, cable laying, etc.

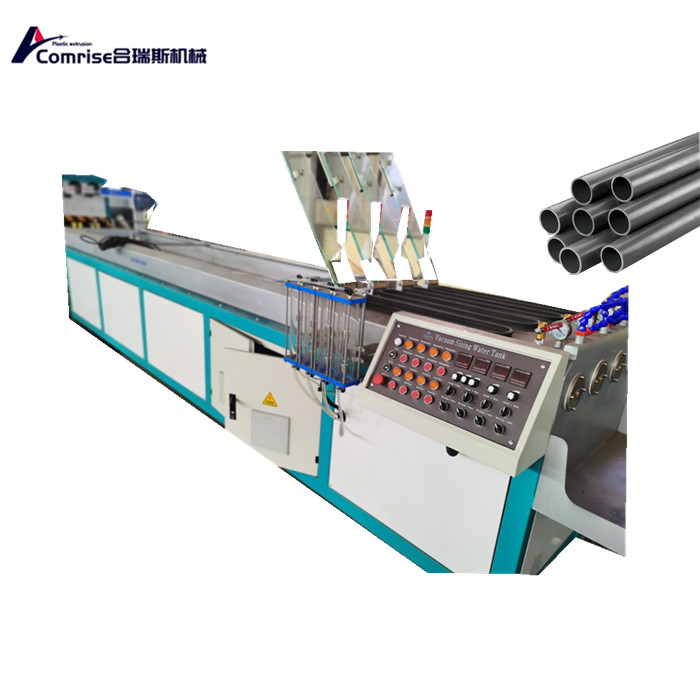

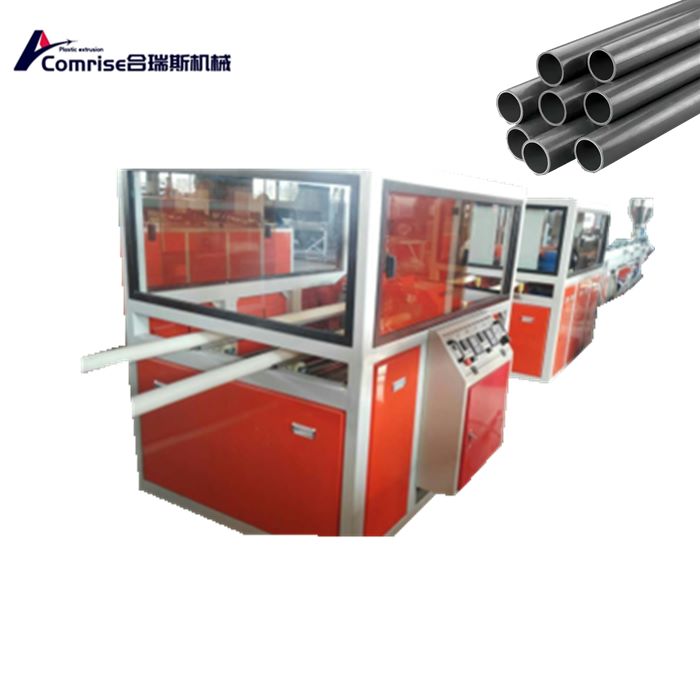

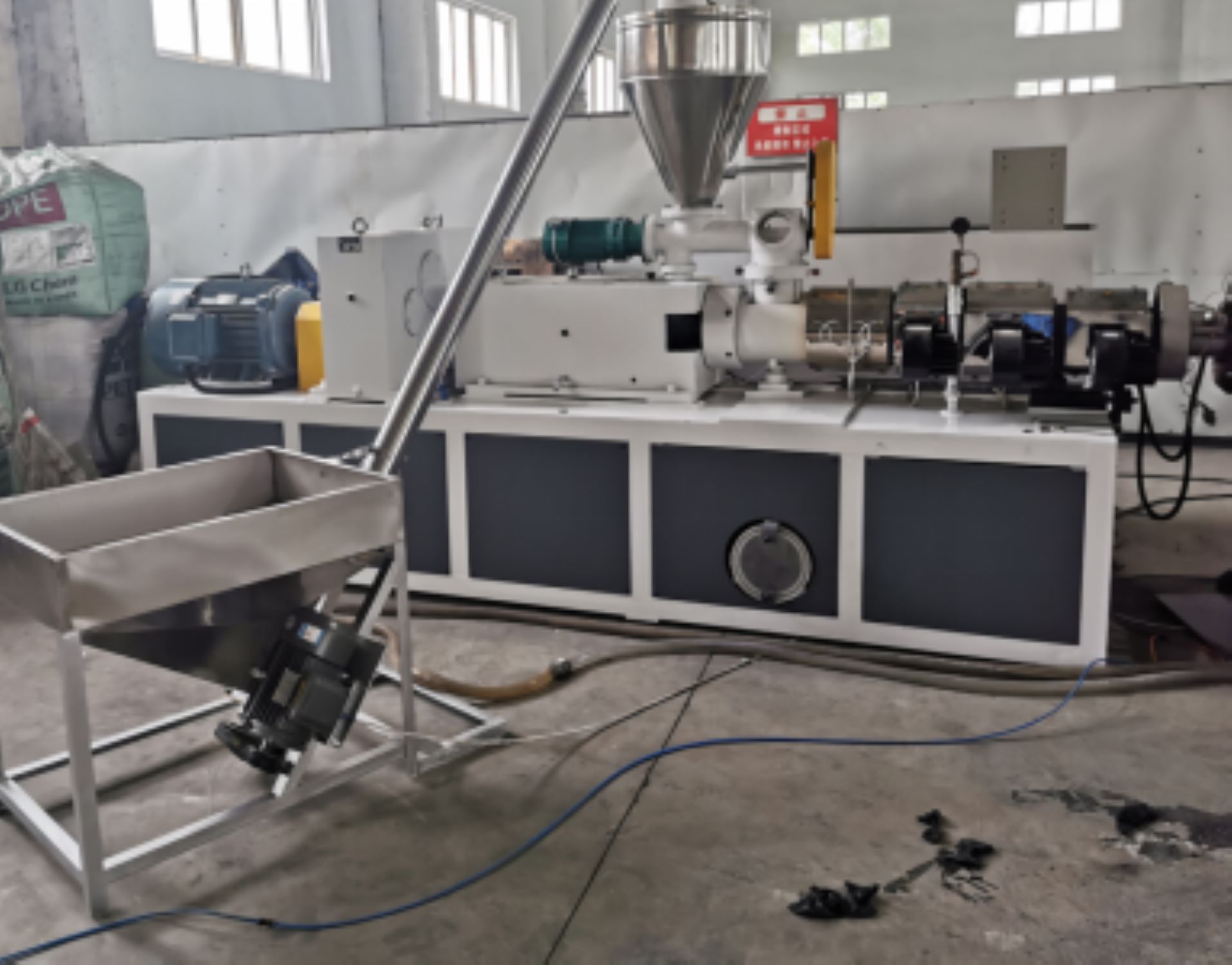

2. The PVC pipe production line consists of a conical twin-screw extruder, vacuum calibration tank, printer, trailer, cutter, stacker crane, etc.

3. The extruder and extractor adopt frequency conversion devices.

4. The vacuum pump and main motor are branded.

5. There are many different types of towing models, such as two claw, three claw, four claw, five claw, and six claw.

Regarding the cutting blade, you can choose between saw blade cutting type or planetary cutting type.

7. We can also provide some auxiliary machines related to PVC pipe making machines.

With its wide range, including various technical solutions, our production not only includes standard machines, but also offers a complete pipe extrusion production line, tailored to customer requirements, still ensuring high performance and competitive prices.

PVC pipe machines can produce PVC pipes with diameters ranging from 16mm to 630mm.

High Efficiency PVC Pipe Production Line

Four cavity

If the diameter of the PVC pipe to be made is less than 32 millimeters, a high-capacity machine (four cavity mold) can be selected, which can produce 4 pipes at the same time.

Double cavity

If you want to make PVC pipes with a diameter less than 75 millimeters, you can choose a semi high capacity machine (double cavity mold) that can produce 2 pipes at the same time.

Single cavity

If we use a single cavity mold PVC pipe making machine, we can increase the diameter of PVC pipes from 12 millimeters to 630 millimeters.

Due to the different diameters of the pipelines, the machine prices will also vary. If you would like to know more detailed information

Price discounts welcome inquiries

GET A QUOTATION NOW