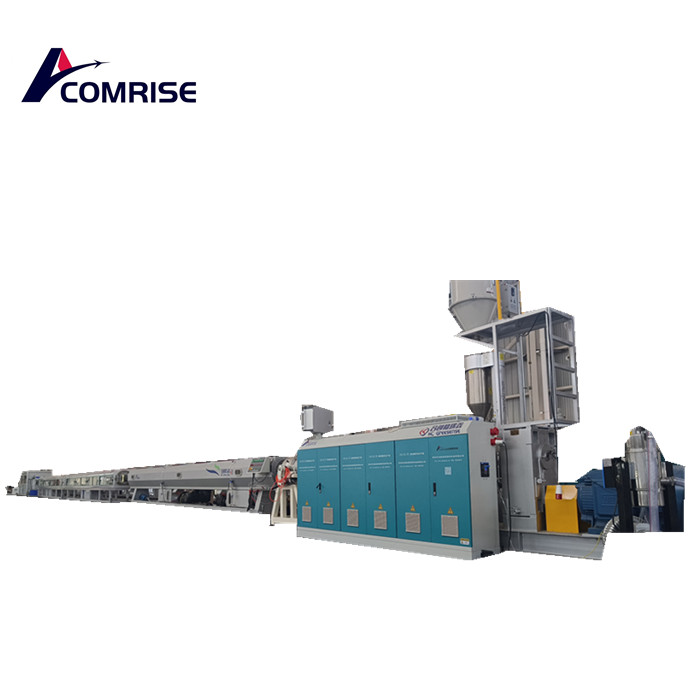

China Optical cable Polyethylene COD HDPE PE bundle pipe hose extrusion machine Manufacturer, Supplier, Factory

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm for that long-term to acquire with each other with buyers for mutual reciprocity and mutual reward for Optical cable Polyethylene COD HDPE PE bundle pipe hose extrusion machine,Plastic Hdpe Optical Microducts Bundle Pipe Tube Hose Extrusion Making Machine Electrical Micro--duct COD Pipe Production Line,Cod Pipe Machine Corrugated Optic Duct for Electric Cable by Extrusion PE Pipe Machine,PE cod fiber optic cable sheathing tube production line/spiral pipe making machine line extruder making machine line,Pe Cod Fiber Optic Cable Sheathing Tube Production Line Pe Cable Spiral Pipe Making Machine Pe Pipe Making Machine, We've been usually looking ahead to forming profitable company interactions with new clientele within the earth.

Optical cable Polyethylene COD HDPE PE bundle pipe hose extrusion machine, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner to suit your needs!

Hot Products

110mm HDPE Pipe Machine

Comrise factory 110mm HDPE Pipe Machine machine Manfacture configuration is different as per produced pipe diameter range. For small diameter range like 20-63mm, there are several different speed models for option, the highest production speed is up to 60m/min for 20×2.0mm HDPE pipes. Big diameter HDPE pipe extrusion line can be designed as two layer co-extrusion type or 3 layer co-extrusion type. Pipe coiler is equipped as an option, to coil pipe size from 16-32mm, or 20-63mm or much big up to 110mm.HDPE Pipe Machine Production Line

Cmrise factory HDPE Pipe Machine Production Line adopts the most advance technology of Europe. It is a new research achievement of energy - saving production lin, which is suitable for high speed extrusion of HDPE, PP and other polyolefin pipe. Compared with cornmon production line, the energy - saving effect reach on 35%, and the product efficiency increase more than 1 times, thus it is not only saving the cost of site and manpower, but also improving efficiency. 110-135mm hdpe pipe machine has nice appearance. higher automatical degree, production reliable and stable.Comrise is china top supplierComposite Winding Pipe Production Line

Comrise Machinery, a top-of-the-line production line supplier, with exceptional quality, ease of use, and unrivaled versatility, the double plastic composite winding pipe production line is the perfect solution for any business looking to streamline their pipe production process. Get in touch with Comrise Machinery today to learn more about this double plastic composite winding pipe production line technology and how double plastic composite winding pipe production line can benefit your business.Solid wall winding pipe machine with high quality

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, PE large-diameter hollow-wall winding pipe production line,Solid wall winding pipe machine with high quality PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line , the plastic coated corrugated pipe production line,PE black jacket insulation pipe production line and PE sheet/board production line, . HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.Corrugated Pipe Extrusion Line

Comrise corrugated pipe extrusion line is a specialized manufacturing system used to produce corrugated plastic pipes, which are widely used in drainage, sewage, electrical conduits, and telecommunications. The Corrugated Pipe Extrusion Line process involves extruding molten material (typically HDPE, PP, PVC, or other polymers) and forming it into a corrugated structure for enhanced strength and flexibility.Advanced HDPE Pipe Extrusion Machine

QINGDAO COMRISE MACHINERY main production line including Advanced HDPE Pipe Extrusion Machine, PE large-diameter hollow-wall winding pipe production line, Solid wall winding pipe machine with high quality PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line, the plastic coated corrugated pipe production line, PE black jacket insulation pipe production line and PE sheet/board production line. HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.