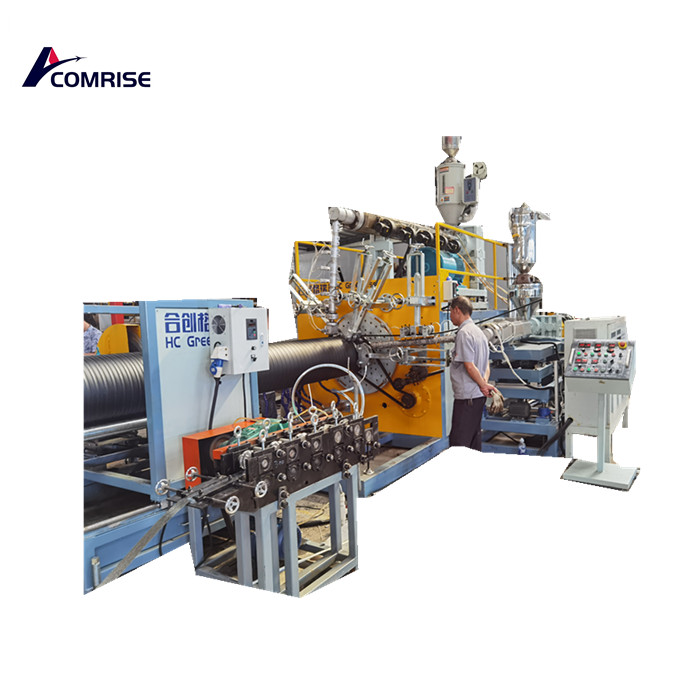

Solid wall winding pipe machine with high quality

Send Inquiry

Production line composition:

Extruder, mold, winding machine and forming mold, melt extruder, vacuum glue system, spray water tank, cutting machine, unloading platform and production control system.

The main features of this production line are:

1. Extruders have advantages such as high plasticization rate, uniform melting, and stable continuous production. High performance gearbox reducer. High torque, long service life, and low noise.

2. Surface nitriding, after nitriding, the product has excellent wear resistance, fatigue resistance, corrosion resistance, high temperature resistance, and long service life.

3. All parts are from well-known domestic and foreign brands.

Characteristics and uses of the products produced:

Solid wall winding pipe machine with high quality

The surface area of the pipe is large, forming the same compressive strength as the pipe soil. The welding effect is good, and the tensile strength of the weld seam is enhanced. The internal reinforcement structure is beneficial for improving the stability of the ring stiffness.

Corrosive sewage pipelines in industries such as seawater, industry, chemical plants, and pharmaceutical factories;

Old city renovation, rainwater and sewage diversion project, sewage treatment plant, garbage treatment plant drainage;

Large scale projects such as municipal and construction engineering buried drainage, power plants, etc;Agricultural irrigation and drainage;

characteristic

This production line adopts two sets of single screw extruders to ensure high-speed and high-quality extrusion. The unique composite die design and spiral rotary forming ensure high efficiency and quality.

Convenient and stable pipelines can be used for manholes and septic tanks, with the advantages of simple installation and safety.

The production of anti-static gas drainage pipes for mining uses specialized fittings, which are very convenient and economical to connect.

This production line can use PP raw materials and use a single screw extruder to produce HDPE large-diameter hollow wall pipes. The quality and specifications of the produced boards meet the requirements of demanding companies.

The extruder is mainly composed of a feeding system, a main extruder, an extruder vacuum system, a screen changer, a metering pump, an extrusion mold, a vacuum shaping mold, a water circulation cooling system, a shaping table vacuum system, a cooling bracket, a traction machine, a longitudinal trimming machine, a horizontal cutting machine, a stacking table, an electrical control system, etc.

A uniquely designed composite die and two sets of extruders are used to extrude PE for winding pipes.

Adopting a unique winding process for pipe forming, high-quality winding pipes are produced. The extruder can move up and down, left and right.

GET A QUOTATION NOW