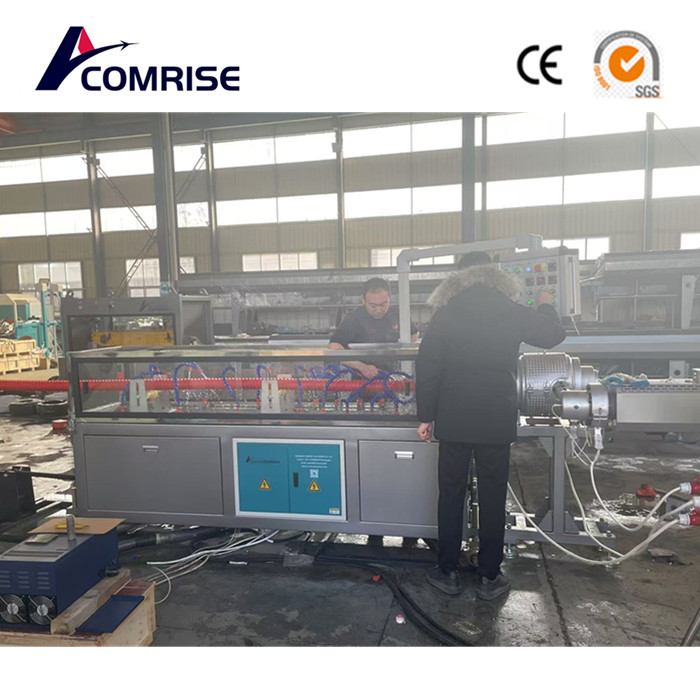

The COD pipe machine for export is currently being installed and debugged at the customer's factory

2025-03-03

The COD tube production line is a very unique machine. Our customers have ordered 8 production lines from our company. Thank you for your trust, and we will strive to do better.

Now let me introduce our company's COD pipe production line.

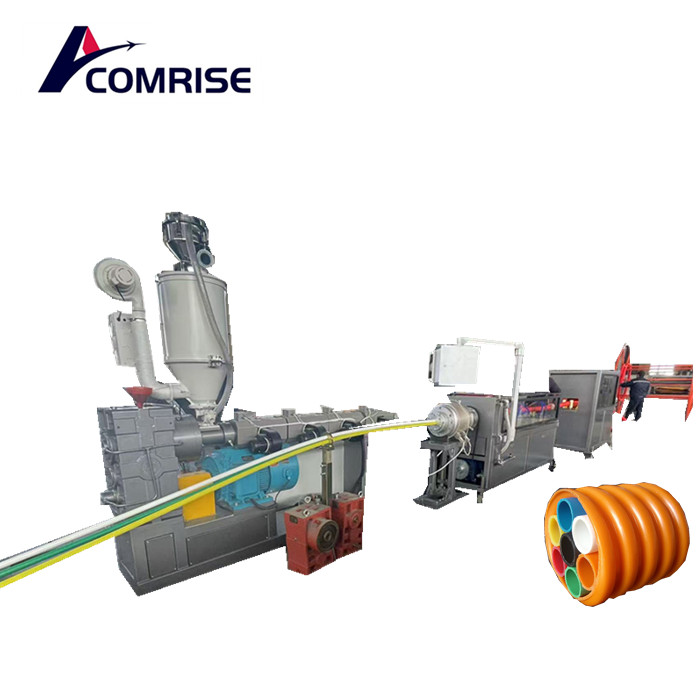

COD cable bundle casing production line

Advantages and functions of cluster tube and COD tube equipment: advantage: High production and processing efficiency. Stable performance and reliable quality. Function: Mainly used for the production and installation of pipeline systems, providing stable and reliable pipeline connections. Can meet the requirements of different engineering applications and ensure the smooth operation of pipelines.

1. The pipe is extruded by the first extruder and then enters the twisting machine, while the basket co extrusion mold forms the shape of the pipe. 2. The pipe material is mainly made of high-density PE.

Main advantages

1.This type of pipeline has the advantages of corrosion resistance, lightweight, easy fixation, and long service life.

2. Pipelines are widely used in highways, municipal construction, apartments, etc. Building drainage UPVC pipe HDPE pipe extruder five layer pipe production line process line

The equipment includes: raw material+masterbatch → mixing → vacuum feeding → material drying → single screw extruder → basket co

extrusion die → calibrator → spray vacuum calibration tank → spray cooling water tank → belt traction → single screw extruder →

coiler → coiler roll forming → water cooler → pipe rack → finished product inspection and packaging

Step 1

COD production machine We use a single screw extruder to manufacture HDPE sub COD. We have the ability to manufacture and

modify machines, so we can easily produce various COD types by replacing molds.

Step 2

Integrated COD is produced through co extrusion process. In this step, the sub COD and external COD will be integrated into one line.

Application of HDPE pipe extrusion production line: agricultural irrigation water pipe&sewage drainage pipe&gas supply pipe

Production process: material → color mixer → material feeding → single screw extruder → extrusion die and calibrator → vacuum

calibration cooling tank → spray cooling tank → printer → traction device → cutting machine → stacker or coiler Equipment

characteristics:

1.The maximum linear extrusion speed is 25m/min, with large capacity and low power consumption, achieving multi-layer co extrusion of 1-3 layers Unique design.

2. The unique design (barrier, shear, and mixing zone) ensures uniform plasticizing effect and reduces pressure on the screw, ensuring high-speed and intelligent shape, compact and stable outputcapability.

3. The high torque gearbox has intelligent design, compact structure, low noise, high load-bearing capacity, high

transmission efficiency, and can ensure long-term trouble free operation. The PP-R pipe extrusion production line manufacturing

machine is developed based on advanced European technology and years of research and development experience in plastic machinery.

A whole line with advanced design, reasonable structure, high reliability, and high degree of automation.

GET A QUOTATION NOW