China WPC Profile Machine Line Manufacturer, Supplier, Factory

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for WPC Profile Machine Line,WPC Wall Cladding Panel Profile Making Machine,WPC Parclose Profile Machine for Windows,WPC PVC Fence Profile Extrusion Machine,WPC Profile Making Machine, "Quality first, Price lowest, Service best" is the spirit of our company. We sincerely welcome you to visit our company and negotiate mutual business!

WPC Profile Machine Line, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

Hot Products

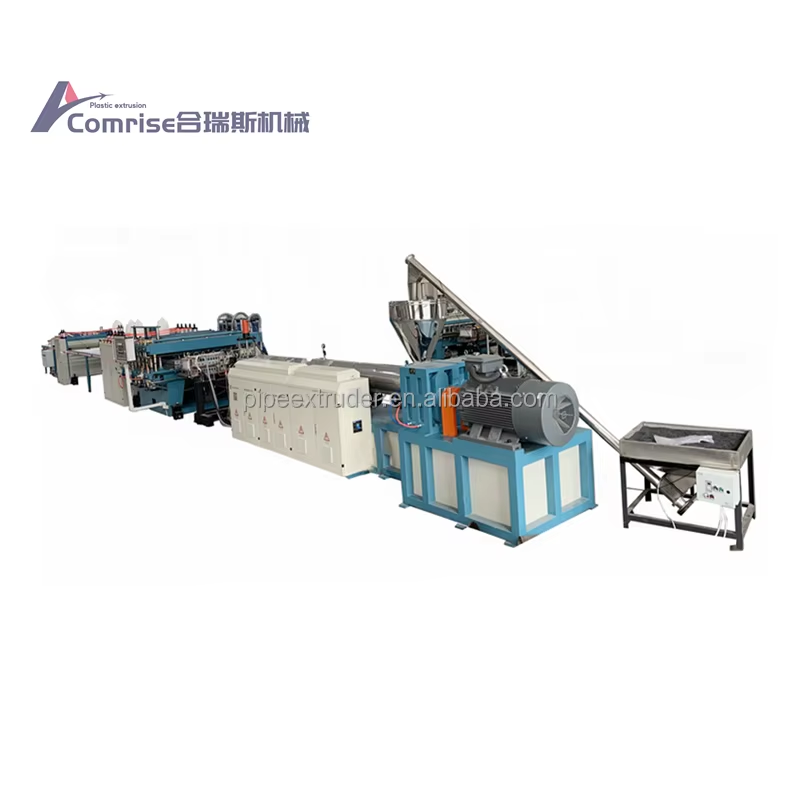

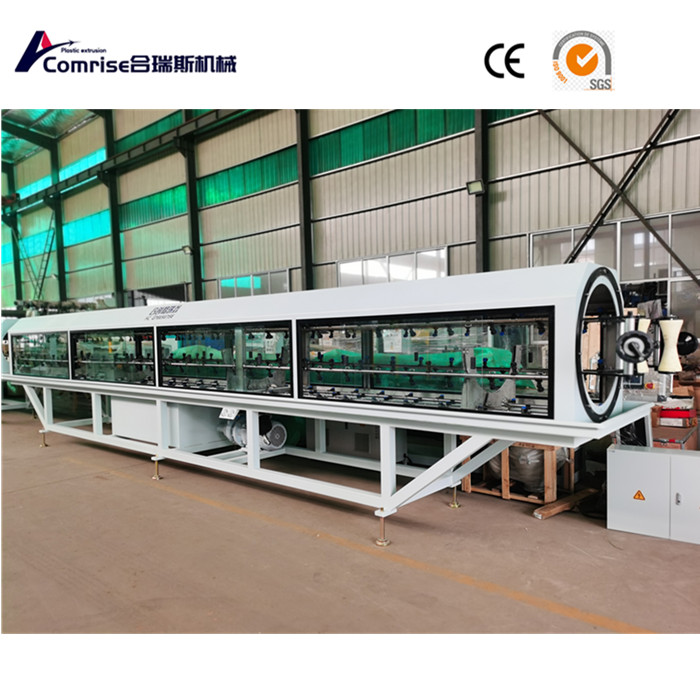

75-250mm Mpp Pipe Extrusion Machine

Comrise Machinery is a top-notch 75-250mm Mpp Pipe Extrusion Machine supplier and manufacturer with over 20 years of experience. Comrise expertise in the industry allows us to offer a range of high-quality 75-250mm Mpp Pipe Extrusion Machine that cater to your needs. Comrise Machinery is the top choice for anyone seeking a quality 75-250mm Mpp Pipe Extrusion Machine supplier and manufacturer. Comrise commitment to quality, and competitive pricing make us the perfect supplier and partner for all your 75-250mm Mpp Pipe Extrusion Machine needs. Contact us today to learn more about Comrise high efficient 75-250mm Mpp Pipe Extrusion Machine and services! Cell:+8613780696467.Three layer hdpe co extrusion pipe machine line

Comrise PE pipes are commonly used for urban water supply, transportation of natural gas and gas, food and chemical industries, transportation of ore and mud, replacement of cement pipes, cast iron pipes, and steel pipes.china pipe factory 315-630mm three layer hdpe co extrusion pipe machine line price good. Ppr pipes are widely used in the fields of building water supply and drainage, urban and rural water supply and drainage, urban gas, electricity, and fiber optic cable sheaths, as well as in the construction, municipal, industrial and agricultural sectors, industrial fluid transportation, and agricultural irrigation.Pe Hollow Wall Winding Pipe Machine

This is where companies like COMRISE come in, offering professional services for larger diameter pe hollow wall winding pipe machines that play a crucial role in the construction of underground sewage systems. As the world’s population continues to grow, so does our need for proper infrastructure. One of the essential components of any modern society is an efficient sewage system that ensures clean water and a safe environment.Pe Plastic Pipe Extruding Machine

Looking for the perfect HDPE pe plastic pipe extruding machine? Look no further than the China Comrise. With its advanced design, our pe plastic pipe extruding machine excels in producing high-output HDPE PE pipes and tubes of all sizes. And with our user-friendly interface, even those new to the industry will find it easy to operate. What sets the China Comrise apart from our competitors is our commitment to quality and customer satisfaction. Our team of experts is dedicated to providing you with the best possible products and services.PVC Imitation Marble Sheet Machine

The high quality PVC Imitation Marble Sheet Machine manufactured by Comrise Machinery is efficient and easy to use. Comrise advanced PVC Imitation Marble Sheet Machine is equipped with new technology and features automated controls that make the operation of the machine user-friendly.Sewage and Drainage Solid Wall Spiral Winding HDPE Pipe Machine

Comrise machinery specializes in manufacturing Sewage and Drainage Solid Wall Spiral Winding HDPE Pipe Machine. We offer a complete range of solutions for the production of high-quality HDPE pipes used for a variety of applications including drainage systems, sewage systems, and industrial applications.

China supplier for HDPE solid wall spiral pipe machine are designed with advanced technology to ensure high productivity and efficiency while minimizing operational costs. We also provide comprehensive technical support and after-sales service to ensure our clients can operate our machines with ease and have minimal downtime.

If you're searching for a reliable and efficient HDPE solid wall spiral pipe machine manufacturer, look no further than our company.