Three layer hdpe co extrusion pipe machine line

Send Inquiry

315-630mm HDPE Pipe Extrusion Production Line:

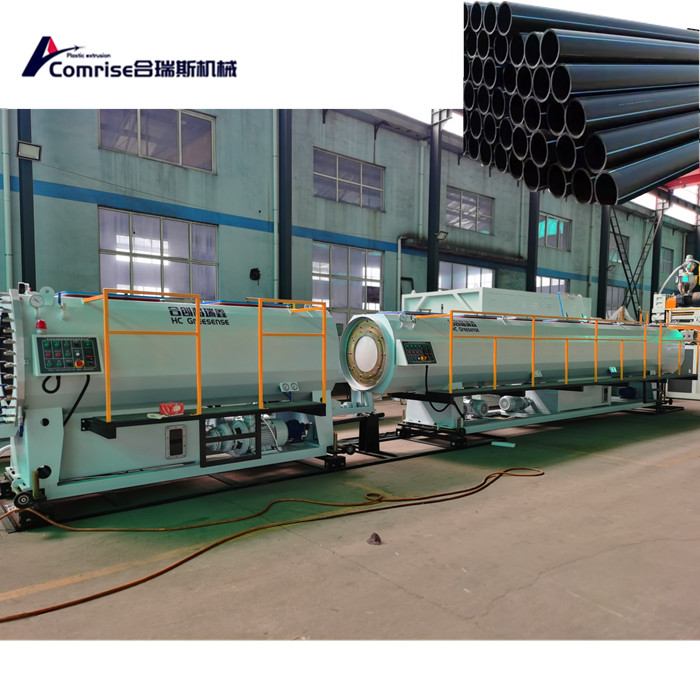

1. The three layer HDPE co extrusion pipe machine line can be used to produce HDPE pipes of 315 and 630 millimeters.

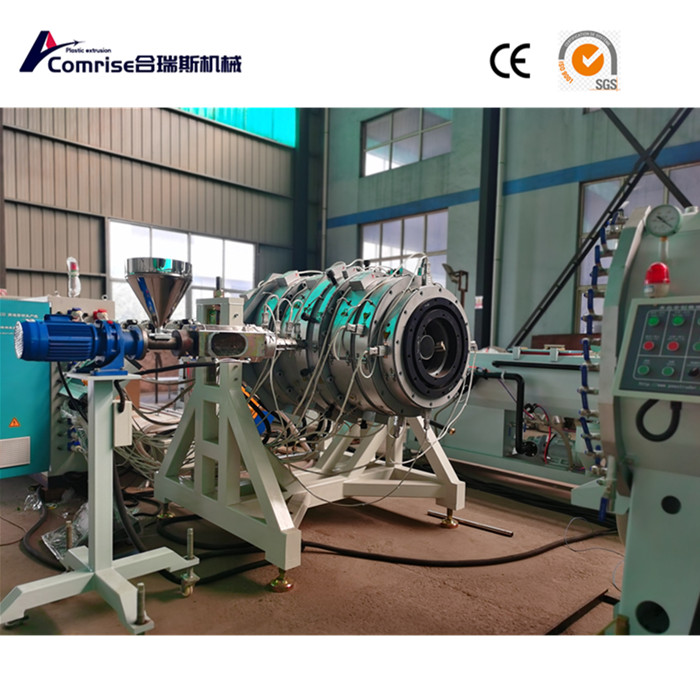

2. The SJ120 extruder adopts high-efficiency screws with an L/D ratio of 33:1 and is equipped with a high torque motor, resulting in high production efficiency.

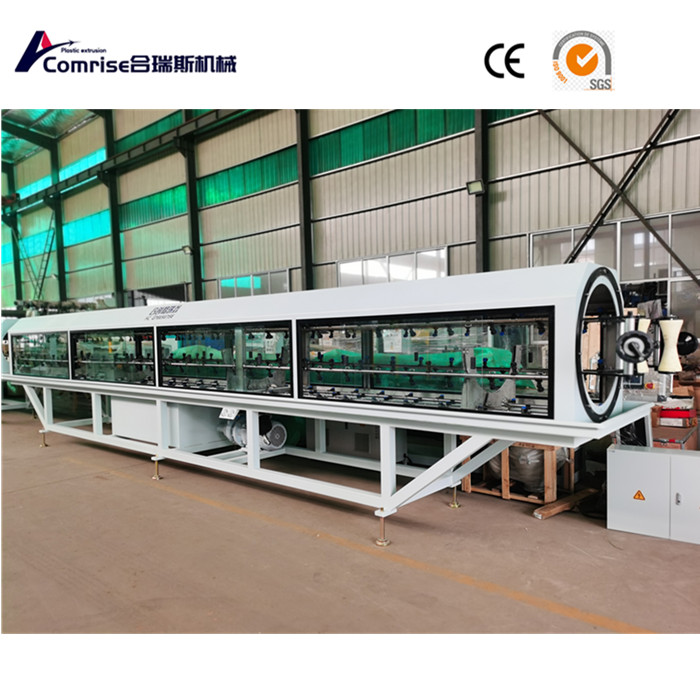

3. The vacuum calibration tank and cooling tank are both made of stainless steel, and they use high-quality vacuum pumps and pumps. They have a moving guide rail under the machine, which is easy to operate.

4. 8 Claw towing machine with variable frequency control, high clamping force, and smooth traction.

5. The cutting machine is controlled by PLC and performs circular cutting with a smooth cut.

6. The electrical components of the machine are sourced from ABB, Siemens, Omron, and Schneider brands, ensuring stable operation and long service life.

1. High output: Ensure that you have the highest output compared to other products

2. New technology gearbox: high torque gearbox

3. Screw and barrel: Bimetallic material ensures a longer working life for you, ensuring 24 months

4. Electrical components and boxes: detachable, with world-renowned brands such as ABB, Siemens, Schneider, Delta, and well-organized.

5. HYPET PLC control system: easy to operate, fully managed, energy-saving, counting, intelligent control system

6. Pipeline brightening device: make the pipeline glow smoothly

7. Vacuum tank made of 304 stainless steel: automatic control of water level and temperature

8. Chip free cutting machine: in the new cutting pipeline equipment, to save materials

Comrise China top pipe factory HDPE pipe making machine is used for the production of HDPE water and gas pipelines, with excellent rigidity and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress cracking resistance, creep deformation resistance, thermal coupling, etc. Therefore, this three layer hdpe co extrusion pipe machine line is the preferred gas and water pipe for urban and suburban pipeline systems, and large-diameter HDPE pipes are beginning to play a very important role in urban water and gas supply systems.

The extruder system consists of two parts, one is the mechanical part, which is composed of a gearbox, screw barrel, hopper dryer, and automatic feeder, and the other is the electrical part, which is composed of Omron temperature control, Schneider contactor, ABB frequency converter, and Siemens motor.

The extruder adopts a large L/D and multiple mixing structures, which are more suitable for low-temperature extrusion production of PE, PP, PPR

This vacuum can is made of 304 stainless steel and is used for forming and cooling pipes to achieve standard pipe sizes. We use a dual chamber structure. The length of the first chamber is very short to ensure very strong cooling and vacuum functions. Due to the fact that the calibrator is placed at the front of the first chamber and the shape of the pipeline is mainly formed by the calibrator, this design ensures fast, better shaping and cooling of the pipeline.

The traction device adopts a special armrest structure, which is easy and convenient to operate; The armrest clamping adopts a mechanical and pneumatic combination system, which is more reliable.

The towing device can provide sufficient traction to stably pull the pipeline. Three layer hdpe co extrusion pipe machine line .According to different pipeline sizes and thicknesses, comrise

factory will customize the traction speed, number of claws, and effective traction length. In order to ensure that the extrusion speed of the pipeline matches the forming speed and to avoid deformation of the pipeline during traction.

GET A QUOTATION NOW