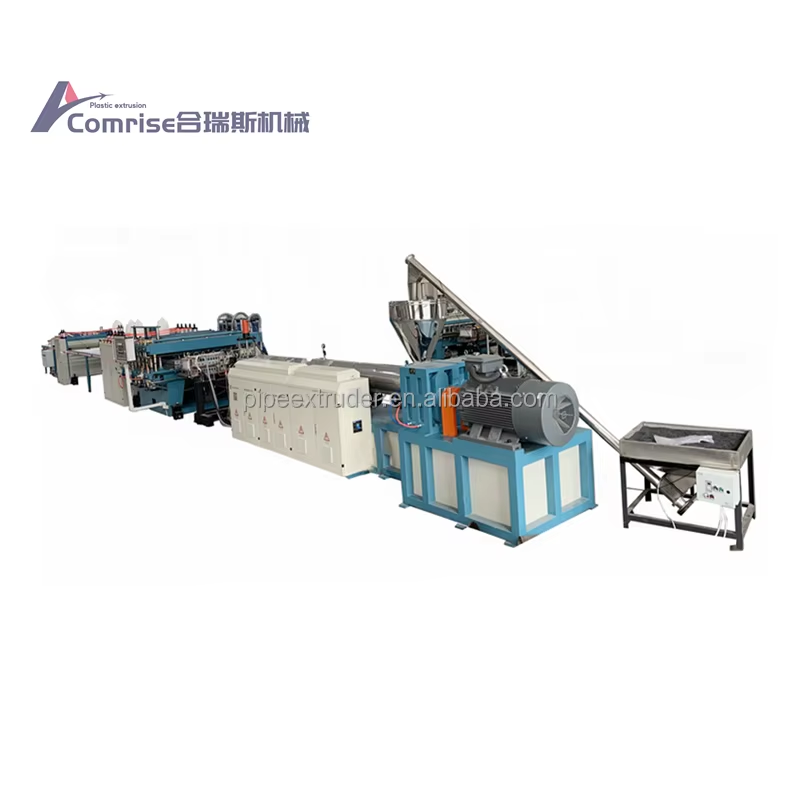

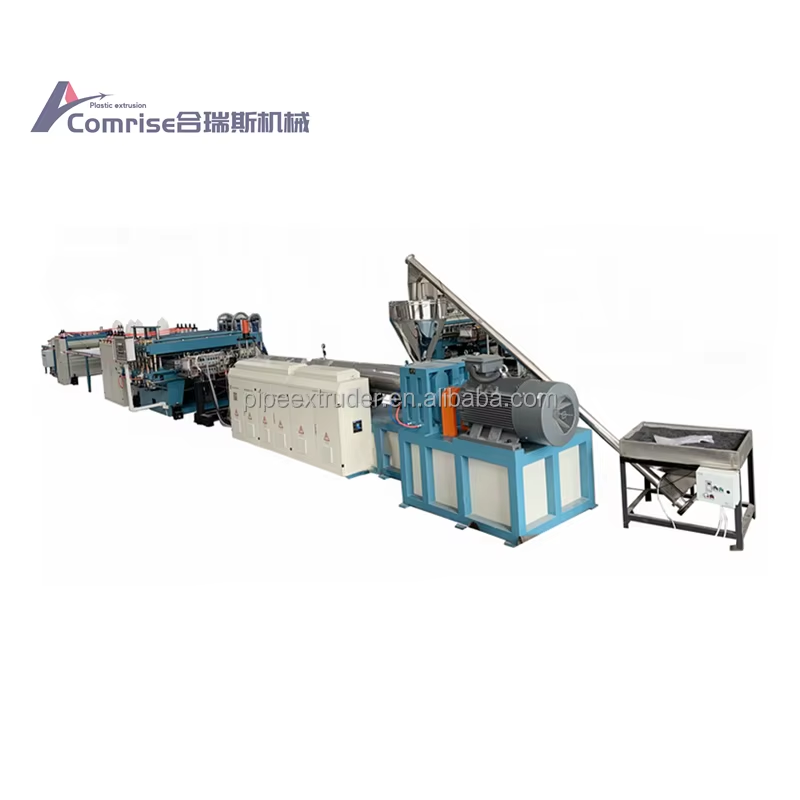

Blister Sheet Extrusion Machine

Send Inquiry

Description:

1. Blister Sheet Extrusion Machine is a combination of extruder, mould, three roll calender, temperature controller, hauling machine,

cutting machine and electric control cabinet.

2. Screw and barrel adopt superior alloy steel (38CrMoAIA) with nitriding treatment, which is high hardness, strong corrosions

resistance and long operating life.

3. Good plasticizing, high output and stability, full automatic controlled by PLC.

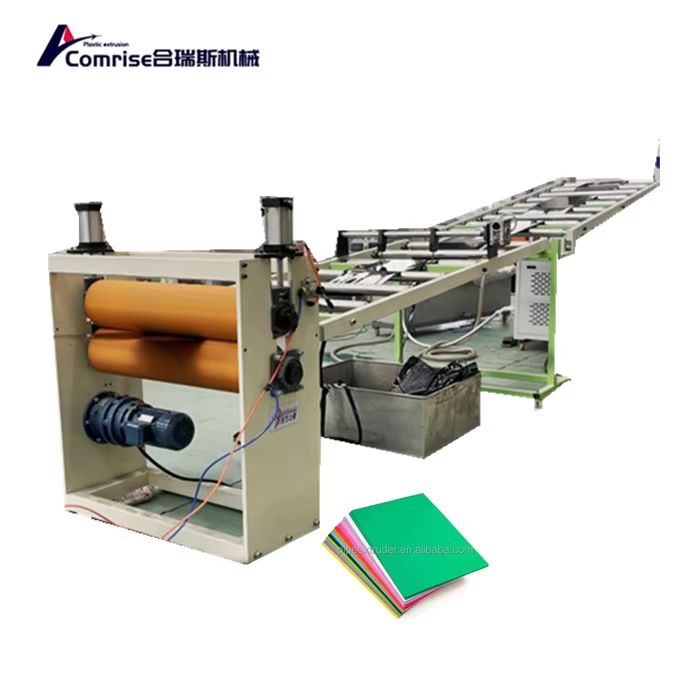

4. This machine is suitable for mono-layer or multi-layer ABS, PC, PS, HDPE plastic sheet. It's widely used in the fields of

luggage, refrigerator, air conditioner, advertisement, bathroom, automotive trim etc.

Single screw extruder SJ 75/33S

J 75-33/1 single screw extruder (reducer adopts Changzhou remote control or Jiangyin Oudian hard tooth surface reducer, screw cylinder adopts Zhejiang Zhoushan screw, main motor adopts Rongcheng Telida, frequency converter adopts Shenzhen Victron or Inweten, Omron temperature controller from Japan, contactor adopts Ximenzi brand)

A. The reducer gears are made of high-quality alloy steel and undergo gear grinding treatment, giving the entire gear the advantages of shock absorption, low noise, wear resistance, and long service life. All lubrication points inside the box are forced lubrication, and the lubricating oil is equipped with an efficient water cooling system.

Mold

A. Mold: Product width: 700 millimeters., Can adapt to products with a thickness of 0.32mm.

B. The mold material is made of imported high-quality heat-resistant alloy steel 5crnimo.

C、 The mold structure flows towards the hard chromium coating and is adjusted with auxiliary micro screws.

D、 The mold is divided into 5 zones for heating and 2 zones for backup

E. The heating method is to heat the core part of the heating rod.

Three roll optical press machine

A. Structure; Tilt three rollers

B. Number of rollers; Three pieces

C、 Drum diameter: 400 millimeters

D. Roller length: 1100 millimeters

E. Wall thickness of roller: 25mm

F. Drum: Made of alloy steel, after hard treatment, the hardness can reach RC65

G. Roller surface treatment: mirror finish, fine polishing.

H. The roller structure adopts a multi-layer composite rapid exchange medium system to ensure constant roller temperature.

Air transport cooling device

A. Number of empty rollers: 18

B. Diameter of air conveying roller: 75mm

C. Length of air conveying roller: 1100 millimeters

D. Surface treatment of air conveying roller: stainless steel

E. Length of air delivery device: 8 m

F. Using a gold cutting knife: 2

Traction device

A. Traction rubber roller: one set

B.Blister Sheet Extrusion Machine Traction diameter: 240 millimeters

C. Traction length: 1100 millimeters

D. The Blister Sheet Extrusion Machine surface of the traction rubber roller is coated with corrosion-resistant, temperature resistant, and wear-resistant rubber and polished

E. The Blister Sheet Extrusion Machine deceleration transmission system adopts a reducer transmission

F. Equipped with a 1.5KW frequency converter

G. Auxiliary three roll press and traction speed control system, tractor can have independent speed control system

GET A QUOTATION NOW