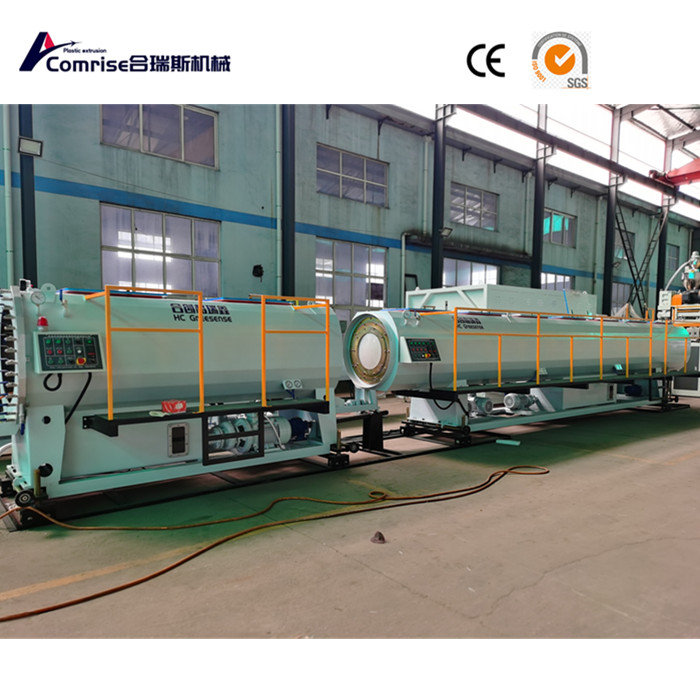

The 315-630mm HDPE pipe production line is being produced

2025-06-12

The production line with high efficiency single screw extruder and through the spiral or basket type mould by multi – Crawler traction machine vacuum sizing cooling and as is known to all, large-diameter PE pipe are tractive pipe variety, specially developed rapid traction switching device, so as to solve the the problem. By the appropriate transformation part of the unit, you can achieve a two-layer or multi-layer co extruded, replacing the extruded layer material or add special materials according to the requirements of the use, such as flame retardant, antistatic, corrosion resistance, nano antibacterial materials, greatly improving the pipe use, reduce raw material consumption, thereby reducing the cost of pipes.

HDPE series plastic pipe production line is mainly used for producing pipe of waster supply and drainage in the field of agriculture and construction etc.

This machine consists of extruder, mould, vacuum calibration tank, haul off unit. Cutting unit, stacker etc.

The single screw extruder and haul off unit apply famous A/C frequency conversion speed regulation device, both vacuum pump and water pump apply famous brand.

The haul-off unit includes two-claw type, three-claw type, four-claw type, six claw type,eight-claw type, ten-claw type, twelve-claw type etc.

Dust free cutting machine, saw blade cutting machine or planetary cutting machine can be applied, the property of machine group is reliable.

The planetary cutting machine is controlled automatically with computer, it has such advantages of simple operation, reliable performance etc. It has reached international advanced level.

The production efficiency is high with special device.It can also produce PP, PE, ABS, PPR, PEX, Silicon core pipe etc.

We also have 2 layers/3 layers HDPE PPR pipe making machine extrusion production line.

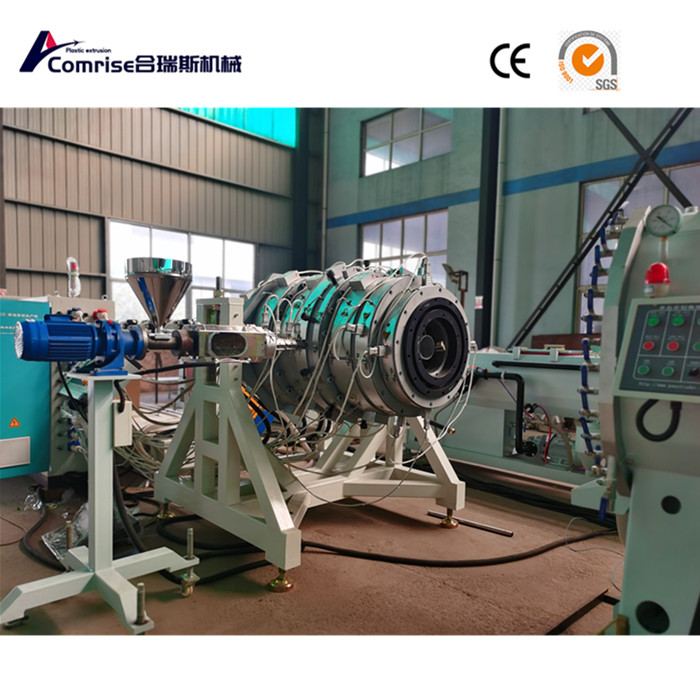

Extruder Machine

1. Simple structure, convenient operation and easy maintenance.

2. Extrusion process is stable and product quality is reliable.

3. Suitable for extrusion processing of various plastic materials, with high versatility.

4. The working parameters of the extruder can be adjusted according to needs to achieve the production of different products. The single screw extruder can provide higher production efficiency and lower energy consumption during the extrusion process. By adjusting the process parameters of the extruder, the precise control of product size and shape can be achieved.

Mould

The mold can be adjusted and replaced according to the different needs of the product, which is suitable for the production of extrusion products of different shapes and sizes, and has high production flexibility.

The extruder mold adopts a molding process, which can ensure the dimensional accuracy and surface quality stability of the product, and reduce the defect and defect rate of the product.

MouldThe mold can be adjusted and replaced according to the different needs of the product, which is suitable for the production of extrusion products of different shapes and sizes, and has high production flexibility.

The extruder mold adopts a molding process, which can ensure the dimensional accuracy and surface quality stability of the product, and reduce the defect and defect rate of the product.

Vacuum Calibration tank

Vacuum sizing box using solenoid valve automatic water control device, to achieve more efficient automated production, reduce

labor consumption, high-quality copper sizing sleeve (material can be selected according to the pipe) can produce a smoother and

more regular pipe.

Water Cooling tank.

The cooling tank has the characteristics of uniform spray, automatic control, strong adjustability, environmental protection and energy saving, wide application range and easy operation.

The cooling tank is usually equipped with an automatic control system, which can realize automatic spray according to the set parameters and procedures, improve production efficiency and reduce manual operation.

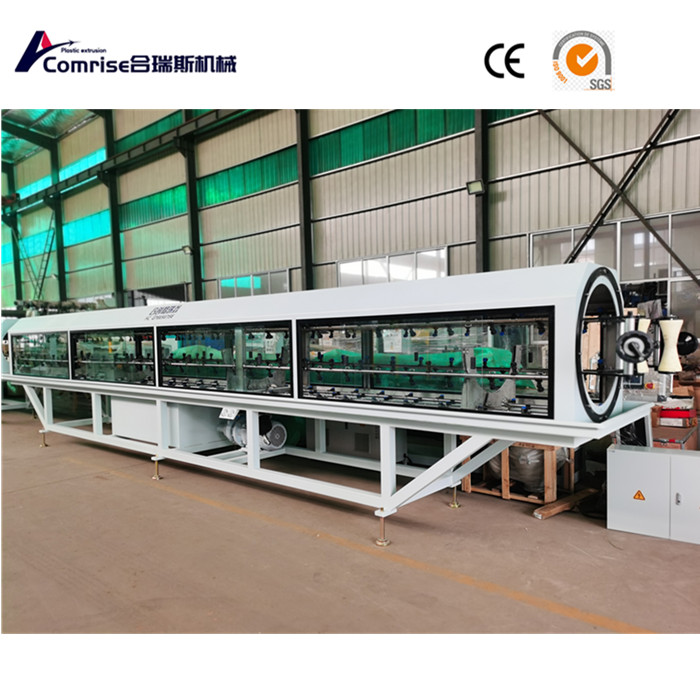

Haul-Off UnitFeatures:

1.Gas compression tightening device

2. Water Tank Filter

3.Rubber module traction device

4.Pipe Support Device Haul off unit provides sufficient traction force to pull pipe stably. According to different pipe sizes and thickness, our company

will customize traction speed, number of claws, effective traction length. To ensure match pipe extrusion speed and forming speed,also avoid deformation of pipe during traction.

Dust-free cutting machine

Dust-free cutting machine has the characteristics and advantages of chip-free cutting, high-precision cutting, high-efficiency production, safety and reliability, multi-functional application and easy operation, etc. It is a very practical and efficient cutting equipment. It is controlled by PLC system.

GET A QUOTATION NOW