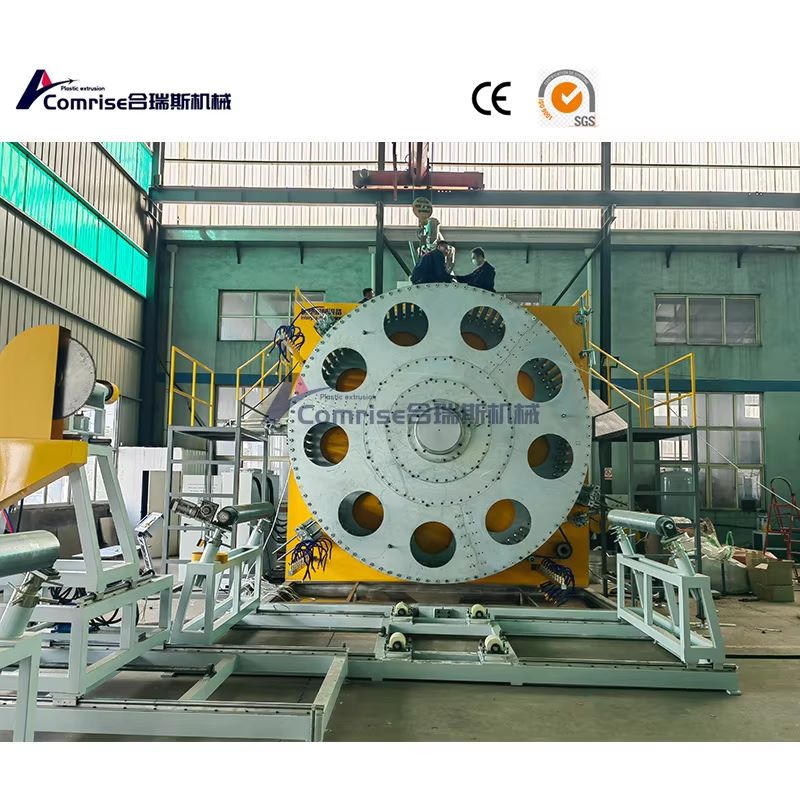

Hollow wall spiral winding pipe production line for shipment

2025-06-06

HDPE large-diameter hollow wall winding pipes (diameter range 200mm-3000mm) have high ring stiffness and prominent strength of the "H" structure. It can be used for about 50 years and has the advantages of low cost, easy operation, vertical pressure, acid resistance, alkali resistance, salt resistance, etc. It is now becoming a substitute for cement pipes and cast iron pipes. Widely used as a sewage pipeline.

Characteristics of HDPE large-diameter hollow pipe winding pipe unit:

The design of HDPE large-diameter hollow wall winding pipe extrusion production line has excellent technology and has been improved based on long-term practical experience. The diameter range can reach 200-3000mm.

Our machines have comfortable operation and high performance/price ratio.

Due to our special design, transportation and installation are very convenient.

We also develop energy-saving methods to save energy consumption during the extrusion of large-diameter hollow wall coils.

Adopting two sets of efficient extruders with high production capacity. Our winding extrusion production line can achieve a stiffness of 4,8,12KN/m2 for the pipes. All parts are precisely designed and manufactured to ensure stable and reliable operation of the entire extrusion production line.

Specially designed for easy maintenance.

The HDPE large-diameter hollow wall winding pipe extrusion production line is mainly used for producing large-diameter hollow wall winding pipes and large-diameter hollow wall urban sewage pipes.

The HDPE large-diameter hollow wall winding pipes (200mm-3000mm) produced by this production line have a unique "I-shaped" structure, which gives them high ring stiffness, high impact strength, low creep resistance per meter weight, resistance to external pressure, corrosion resistance (acid, alkali, salt, etc.), no pollution, and a long service life (up to 50 years). This pipe material is widely used in municipal drainage and sewage systems, and will be an upgraded product of cement pipes, cast iron pipes, ceramic pipes, etc. The low assembly cost, ease of operation, easy connection, and cost savings of this pipe material will make it have a wider range of application prospects and market potential. Production line features: The HDPE large-diameter hollow wall winding pipe production line is designed using advanced technology, equipped with a first single screw extruder (square tube extrusion), square tube extrusion mold, vacuum sizing water tank, spray cooling water tank, second single screw extruder (rubber extrusion), spiral forming machine, cutting machine, and stacking platform. The first single screw extruder (square tube extrusion) and the second single screw extruder (rubber extrusion) are based on the principles of low-energy, low-temperature plasticization (for material characteristics), and efficient extrusion. The unique variable pitch and solid-liquid separation screw design, as well as the unique feeding system design, ensure high-yield extrusion. The special strong mixing section design ensures uniform plasticization of raw materials at low temperatures. Spiral forming machine: adopting advanced multi axle box transmission structure, it has the characteristics of large transmission force, stable operation, and long service life. The unique composite mold, spiral rotary forming, and the design of two extruders ensure efficient extrusion of high-quality wrapped pipes. The second adhesive material single screw extruder can move up and down, left and right. PLC、 The control of the touch screen system truly achieves operational automation and ease of operation. Cutting machine: capable of fixed length cutting, controlled by PLC and touch screen system, truly achieving operational automation and ease of operation. Control system: using PLC and touch screen system for control. Multi point control: Square tube extrusion, PE material extrusion, spiral winding forming, and cutting processes are all synchronously controlled by the control system. The two touch screens can independently control the extruder and winding forming.

The PE large-diameter winding pipe production line consists of special-shaped pipe extruders, fusion extruders, winding forming machines, cutting machines, and related auxiliary equipment. It has the advantages of large production volume, high production efficiency, stable operation, high pipe ring stiffness, small unit weight per meter, excellent creep resistance, convenient connection, and economical construction.

The extruders all adopt specially designed high-efficiency single screw extruders, with unique screw and barrel structures, high output, low energy consumption, excellent plasticization, and reasonable mold structures. The dual machine joint feeding rotary molding is ingeniously conceived and uniquely designed.

Advanced PLC computer control system can be used, which is easy to operate, stable and reliable in action.

Adopting a dual stage pressure reducing screw with special plasticizing elements for promoting mixing, high torque, and high temperature control accuracy.

Adopting a composite machine head, dual machine joint feeding, spiral rotation forming, efficient composite process, to ensure the high quality of the product.

GET A QUOTATION NOW