China PVC WPC Door Machine Production Line Manufacturer, Supplier, Factory

It adheres for the tenet "Honest, industrious, enterprising, innovative" to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for PVC WPC Door Machine Production Line,WPC Door Frame Making Machine,WPC Door Panel Making Machine,WPC Door Frame Machine Parts,WPC Hollow Door Machine, The team of our company along with the use of cutting-edge technologies delivers impeccable top quality products supremely adored and appreciated by our shoppers worldwide.

PVC WPC Door Machine Production Line, We'll supply much better products and solutions with diversified designs and expert services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information be sure to feel free to contact us. We are looking forward to receiving your enquiries soon.

Hot Products

HDPE Pipe Production Machine Line

COMRISE extrusion HDPE Pipe Production Machine Line can be used to produce PE pipes of different diameters, with excellent rigidity and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress cracking resistance, creep deformation resistance, thermal linkage, china factory etc. Therefore, this pipeline production line is the preferred choice for gas, water, and agricultural irrigation pipeline systems between urban and rural areasPVC Coated Steel Pipe Machine

PVC Coated Steel Pipe Machine are a reliable and cost-effective solution for a wide range of applications. With their superior strength, durability, and corrosion resistance, these pipes are ideal for use in harsh environments where other materials may fail. The PVC Coated Steel Pipe Machine is an essential tool for the production of these pipes, ensuring that they meet the highest standards of quality and performance.175mm PP PE MPP Electric Conduit Corrugated Pipe Machine

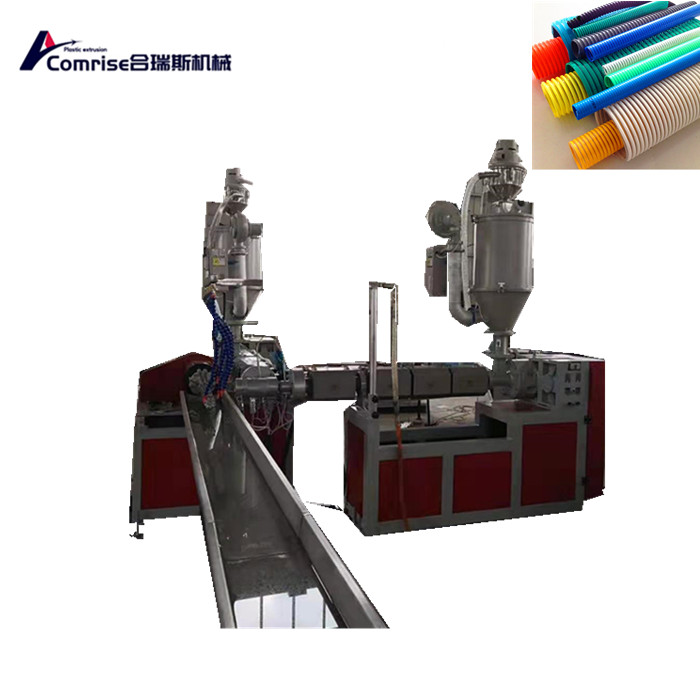

Comrise is a well-known manufacturer and supplier of plastic pipe extrusion equipment in China. Our company is dedicated to providing comprehensive and customized solutions for various plastic pipe productions, including the 175mm PP PE MPP Electric Conduit Corrugated Pipe Machine.Hollow wall winding pipe machine

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, Hollow wall winding pipe machine, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line , the plastic coated corrugated pipe production line,PE black jacket insulation pipe production line and PE sheet/board production line, . HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.Caterpillar Pipeline Machinery

Comrise Machinery is your go-to supplier for top-quality PVC and HDPE caterpillar pipeline machinery. With comrise state-of-the-art technology, customized solutions, and user-friendly design, you can't go wrong with choosing us for your caterpillar pipeline machinery needs. Contact us today to learn more about how we can help you achieve your goals!PVC Fiber Reinforced Soft Pipe Extrusion Line

COMRISE PVC Fiber Reinforced Soft Pipe Extrusion Line is designed to produce PVC soft spiral reinforced pipe, which is widely used in industry , agriculture , architecture , irrigation market and so on.We are china factory PVC Fiber Reinforced Soft Pipe Extrusion Line consists of two sets single screw plastic extruders, mould, forming machine,cooling water tank, rotatory haul off machine and winder.