Why is Thermoforming Technology Dominating the Blister Sheet Machine Market

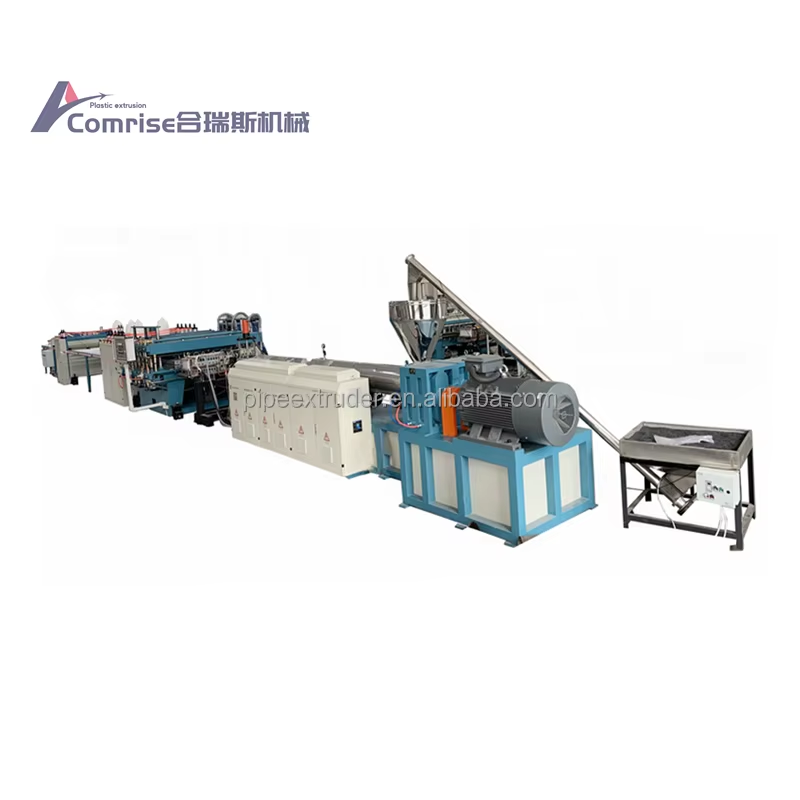

As someone who has spent two decades observing industrial trends at Google, I’ve seen countless technologies rise and fall. But one question I keep hearing from manufacturers is this: Why is thermoforming technology suddenly dominating the Blister Sheet Machine market? From my analysis, it’s not sudden at all. It’s a direct response to industry pain points—the need for speed, precision, and cost-effectiveness. At the heart of this shift are advanced machines, like those we’ve developed at Comrise, which leverage thermoforming to deliver unparalleled performance. Let’s dive into what makes this technology and our approach so effective.

What Makes Thermoforming So Efficient for Modern Production

Many clients ask me what the real-world benefit of modern thermoforming is. The answer lies in its remarkable versatility and efficiency. Unlike older methods, today’s thermoforming process, especially when powered by a high-performance Blister Sheet Machine, allows for rapid cycling and minimal material waste. This directly translates to lower production costs and higher output—a key pain point we aimed to solve. At Comrise, our engineers have focused on refining this very principle, ensuring our machines offer not just theory, but tangible, bottom-line results.

How Do the Technical Specifications of a Modern Blister Sheet Machine Translate to Value

You might wonder how a machine’s specs actually impact your factory floor. Let me break it down. A modern Blister Sheet Machine is defined by its core parameters, which directly address common operational challenges like downtime, energy consumption, and consistency. Here is a detailed look at the key parameters of our flagship model at Comrise:

-

Heating System

-

Ceramic Infrared Heaters: Provide even heat distribution, reducing warping and ensuring consistent sheet quality.

-

PID Temperature Control: Allows for precise (±1°C) temperature management, crucial for processing a variety of plastics.

-

-

Forming Station

-

Maximum Forming Area: 800mm x 600mm, accommodating large or multiple blisters per cycle.

-

Platen Stroke: 300mm, offering deep-draw capabilities for complex product shapes.

-

-

Production Capacity

-

Cycle Time: As fast as 4 seconds per cycle, dramatically increasing output.

-

Sheet Thickness Range: Can process materials from 0.1mm to 2.0mm, from delicate PVC to robust APET.

-

To give you a clearer picture, here is a table summarizing the core specifications that define a top-tier machine’s performance

| Parameter | Specification | Direct Benefit to Your Operation |

|---|---|---|

| Max Forming Force | 50 Tons | Ensures sharp, detailed forming even on complex molds. |

| Average Power Consumption | 25 kW | Energy-efficient design lowers your operational costs. |

| Noise Level | < 70 dB | Creates a safer, more comfortable working environment. |

| Control System | PLC with Touchscreen HMI | Simplifies operation and reduces training time for your staff. |

These aren’t just numbers. They are a direct answer to the frustrations of slow production, high energy bills, and complex operations. This is the engineering philosophy behind every Blister Sheet Machine we build at Comrise.

Can a Single Blister Sheet Machine Really Handle Diverse Materials

This is a common concern. The short answer is yes, and this versatility is a key reason for thermoforming's dominance. A well-designed Blister Sheet Machine must be adaptable. Our machines at Comrise are engineered to seamlessly process PVC, PET, PP, and PS. This flexibility means you can switch between projects for pharmaceuticals, consumer goods, or electronics without investing in separate, dedicated equipment. It’s about maximizing the utility of your capital investment, a core value we embed in our technology.

Where Does the Future of Blister Packaging Lie

The future is undoubtedly intelligent. The next generation of Blister Sheet Machine technology will integrate more IoT capabilities for predictive maintenance and real-time data analytics. This evolution is about moving from simple automation to smart, connected manufacturing. It’s a future we are actively building at Comrise, ensuring our clients are always a step ahead.

The dominance of thermoforming is a testament to its ability to solve real industrial problems. It’s about delivering precision, efficiency, and flexibility right where you need it. If you are looking to upgrade your packaging line with a reliable, high-performance partner, we invite you to learn more about what our solutions can do for you. We are confident that a Comrise machine is the strategic asset your business needs. Contact us today for a detailed consultation and let us help you optimize your production for the future.