How Does a Modern Window Door Profile Machine Truly Elevate Final Product Quality

2025-11-19

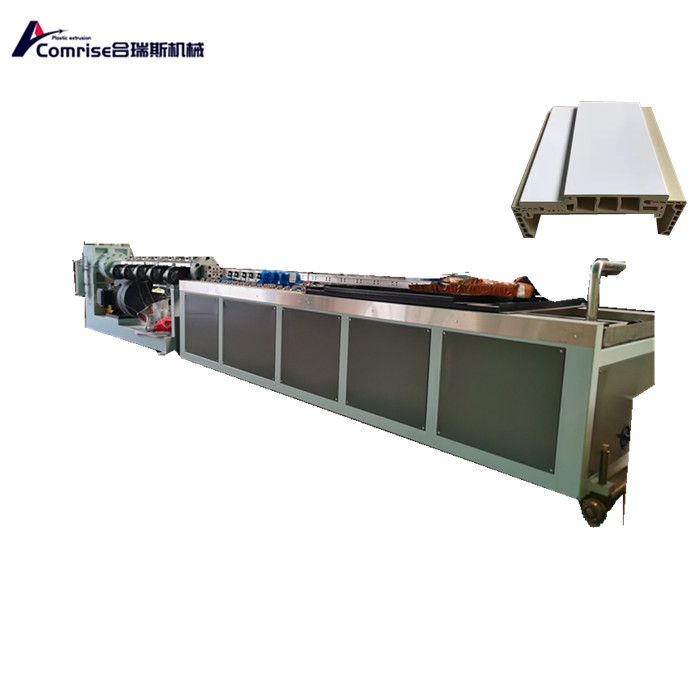

I’ve spent twenty years watching businesses in the fabrication industry search for an edge. They often ask me about SEO tricks or the perfect keyword. But I always tell them the same thing: the foundation of great online visibility is a truly great product. And a great product in your industry starts with the precision of your core equipment. That’s why when we at Comrise set out to re-engineer our flagship Window Door Profile Machine, we didn't just focus on speed; we obsessed over how every single component contributes to the quality of your final window or door. This isn't just a machine; it's your partner in building a reputation for excellence.

So, let’s get into the real question. How does investing in a modern Window Door Profile Machine translate directly to a superior product that you can hold in your hands and feel the difference?

What Core Mechanisms Inside a Window Door Profile Machine Guarantee Dimensional Perfection

The old adage "garbage in, garbage out" applies here, but with a positive spin. "Precision in, perfection out." The journey to a flawless profile begins the moment the raw material enters the machine. Dimensional inaccuracies here create a ripple effect of problems down the entire production line, leading to poor sealing, difficult assembly, and customer callbacks.

A modern Window Door Profile Machine from a brand like Comrise tackles this through several integrated, high-precision systems:

-

A Servo-Driven Feeding System: Unlike older hydraulic systems, our servo-driven system provides digital control over the feed rate. This eliminates the slight variations that can cause material stretch or compression, ensuring every meter of profile is fed with consistent tension.

-

Precision-Ground Tooling and Gearboxes: The cutting and processing heads are the heart of the operation. We use tooling manufactured to tolerances of less than 0.01mm. This ensures that every cut, every groove, and every drill hole is exactly where it's supposed to be, every single time.

-

Rigid, Vibration-Dampening Frame: A machine that shakes is a machine that makes mistakes. Our welded steel frame is engineered with specific internal damping structures that absorb operational vibrations, allowing the tooling to work on a perfectly stable platform.

Let’s look at the parameters that define this precision.

Key Parameters for Unmatched Dimensional Accuracy

| Parameter | Comrise Standard | Industry Standard | Impact on Final Product Quality |

|---|---|---|---|

| Cutting Length Accuracy | ±0.05 mm | ±0.1 mm | Eliminates gap issues in corner assembly, ensuring perfect sealing. |

| Linear Guide Straightness | ≤ 0.02 mm/m | ≤ 0.05 mm/m | Prevents profile "walking" during processing, guaranteeing straight, true profiles. |

| Servo Motor Positioning | 24-bit absolute | 17-bit incremental | Provides repeatable precision that doesn't drift over time or after a power cycle. |

How Does a Advanced Control System Act as the Intelligent Brain Behind Consistent Quality

Precision mechanics are nothing without intelligent control. The operator interface is where the human ambition for a perfect product meets the machine's capability to execute it. A confusing or simplistic control system introduces human error, which is often the weakest link in the quality chain.

Our Comrise Window Door Profile Machine features a centralized CNC system that does more than just issue commands. It’s a collaborative partner.

The system stores hundreds of profile recipes, allowing you to switch from one complex window design to another with a single tap. This eliminates manual adjustment errors. Furthermore, real-time monitoring of motor torque and spindle load can predict a dull tool or a material jam before it ruins a batch of expensive profiles. This isn't just automation; it's predictive quality assurance. The system ensures that the tenth thousandth profile it produces is identical in quality to the first.

Can the Right Window Door Profile Machine Directly Impact Your Product's Structural Integrity and Finish

Absolutely. The quality of a window or door isn't just about how well the pieces fit together; it's about strength, durability, and aesthetic appeal. A machine that creates stress points or leaves burrs and rough edges is fundamentally undermining your product's value.

Our Window Door Profile Machine addresses this through technologies designed to protect the material:

-

Low-Stress Clamping: Customizable, pneumatic clamping fixtures hold the profile securely without deforming or marring the sensitive surface, which is crucial for pre-finished materials.

-

High-Frequency Spindles with Constant Power: These spindles maintain speed under load, ensuring a clean, chatter-free cut on materials from soft uPVC to hard aluminum alloys. A clean cut means no micro-fractures that can become failure points later.

-

Integrated Deburring and Dust Extraction: Many operations treat deburring as a separate, manual step. Our machines can integrate an automatic deburring tool and a powerful vacuum system that leaves the profile ready for the next stage, reducing labor and handling damage.

The following table illustrates the direct correlation between machine features and the final product's attributes.

From Machine Feature to Tangible Product Benefit

| Machine Feature | Direct Impact on Product Quality |

|---|---|

| Automatic Tool Path Optimization | Smother internal channels and grooves, leading to easier gasket and hardware installation. |

| Temperature-Controlled Spindle | Consistent cut quality from the start of the shift to the end, regardless of ambient temperature. |

| Laser-Assisted Positioning | Perfectly positioned hardware mounting holes, ensuring smooth operation of locks and hinges for the life of the product. |

Your Top Questions on Window Door Profile Machines Answered

We believe an informed customer is our best partner. Here are answers to some of the most common questions we receive.

What is the typical lead time for a new Comrise Window Door Profile Machine

We understand that time is money. Our standard lead time is 8-10 weeks from order confirmation. This period includes the custom assembly and the rigorous 72-hour continuous testing cycle we put every machine through to ensure it meets our performance standards before it leaves our factory.

Can your machine be integrated with existing downstream automation like welding or copying centres

Yes, seamless integration is a core design principle. Our Comrise machines are equipped with standardized communication protocols (like Profinet and Ethernet/IP) and programmable I/O ports. We work with your team to ensure the machine can feed data and components directly into your existing welding stations or other automation, creating a unified and efficient production cell.

What kind of training and support does Comrise provide after purchase

We provide a comprehensive support package. This includes on-site installation and commissioning by our expert engineers, who will train your operators on-site for a full week. Furthermore, you receive 12 months of access to our online video library and 24/7 remote support via a dedicated platform. We see your purchase as the beginning of our partnership.

Ready to Build Your Reputation for Quality from the Ground Up

After two decades in this field, I can tell you with certainty that the brands that thrive are the ones that never compromise on the fundamentals. Your Window Door Profile Machine is the most fundamental piece of equipment in your line. It defines the ceiling of your product's potential quality.

At Comrise, we haven't just built a machine. We've engineered a solution for fabricators who are tired of the compromises and want to deliver products that stand the test of time. This is your opportunity to stop fighting your equipment and start leveraging it as your greatest competitive advantage.

Don't just make profiles. Craft legacies.

Contact us today to schedule a live, virtual demonstration. Let's discuss your specific profile challenges and show you how the Comrise Window Door Profile Machine can be calibrated to solve them, boosting your quality and your profitability.