China PP Co-extruded Hollow Building Formwork Production Manufacturer, Supplier, Factory

We're experienced manufacturer. Wining the majority in the crucial certifications of its market for PP Co-extruded Hollow Building Formwork Production,PP Hollow Corrugated Board Extrusion Machine,PP Hollow Board Machine,PP Co-extruded Hollow Building Formwork Production Line,The Manufacture Hollow Building Formwork Making Machine, We welcome all with the shoppers and buddies to call us for mutual rewards. Hope to do further more business along with you.

PP Co-extruded Hollow Building Formwork Production, Welcome to visit our company, factory and our showroom where displays various hair merchandise that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to deliver you the best service. Make sure you contact us if you require more information. Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation.

Hot Products

20-63mm Pe Pipe Extrusion Line

China supplier for 20-63mm Pe Pipe Extrusion Line is produce by Comrise machinery, which have 20 more years experience and professional on plastic extruder machinery manufacturing, company have own R&D team, international sale team, service team, their 20-63mm Pe Pipe Extrusion Line export to many countries in the world like Europe, middle east, Africa and Asian countries.HDPE Solid Wall Spiral Pipe Machine

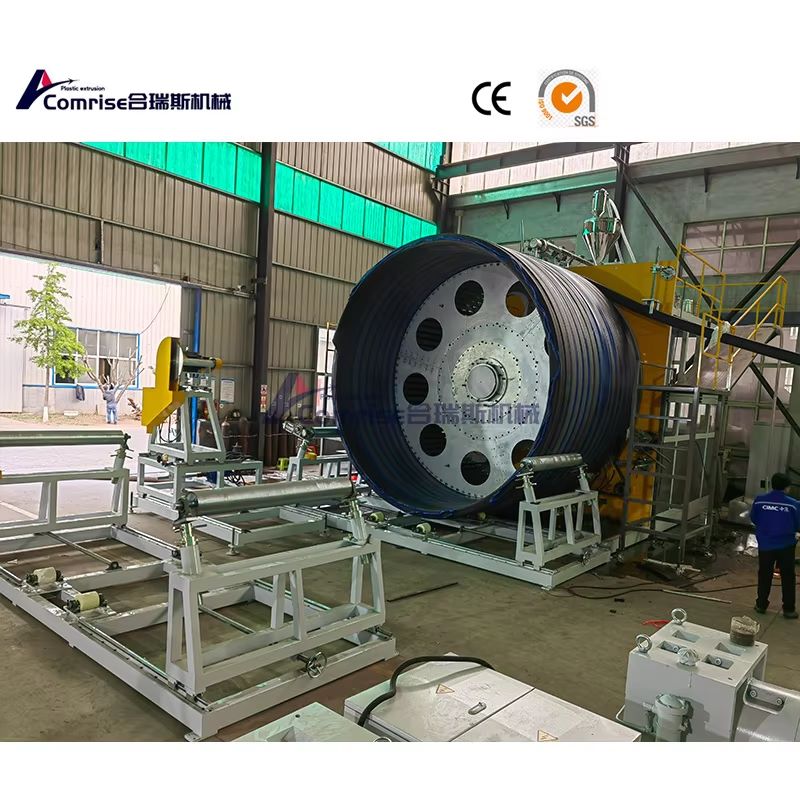

Comrise machinery specializes in manufacturing HDPE solid wall spiral pipe machines. We offer a complete range of solutions for the production of high-quality HDPE pipes used for a variety of applications including drainage systems, sewage systems, and industrial applications.Hollow Wall Winding Pipe Production Line

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, PE large-diameter hollow-wall winding pipe production line, Hollow wall winding pipe production line PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line, the plastic coated corrugated pipe production line, PE black jacket insulation pipe production line and PE sheet/board production line. HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.Corrugated Pipe Making Machine

Comrise durable singlewall Corrugated Pipe Making Machine and doublewall Corrugated Pipe Making Machine, choose what kind of pipe depends on the intended application of the pipes. Singlewall pipes are suitable for lighter, more flexible applications, while doublewall pipes are better for heavierduty, more demanding environments. Both types of pipes play crucial roles in various industries, from automotive and medical to construction and infrastructure.PP Hollow Grid Board Production Machine

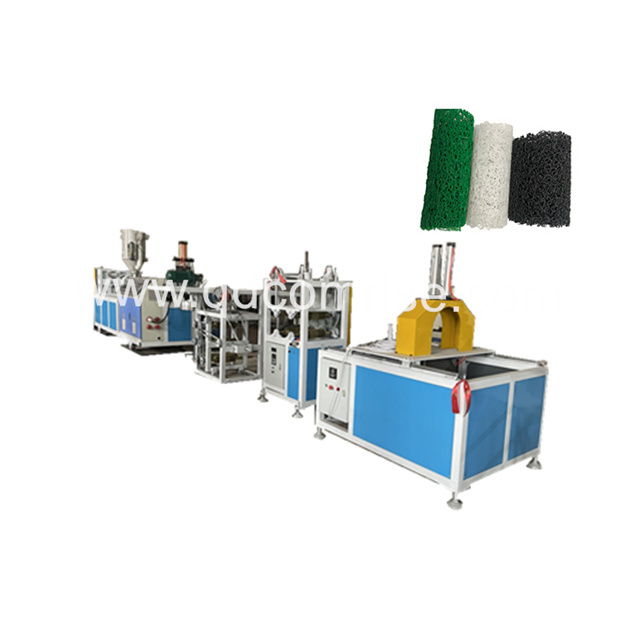

COMRISE PP Hollow Grid Board Production Machine which is equip the single screw extruder,machine with high cost performance. sheet making with width from 1220mm to 2600mm and thickness from 1.5mm to 12mm ,depends to different modelsch model,also we have the co-extrusion type for customer choose we an manufacture.comrise machine factory have the advantage of high output,easy operation,high precision,good products with smooth surface straight rib.High efficiency HDPE pipe production line factory price

QINGDAO COMRISE MACHINERY main production line including High efficiency HDPE pipe production line factory price, PE large-diameter hollow-wall winding pipe production line, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line, the plastic coated corrugated pipe production line, PE black jacket insulation pipe production line and PE sheet/board production line. HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.