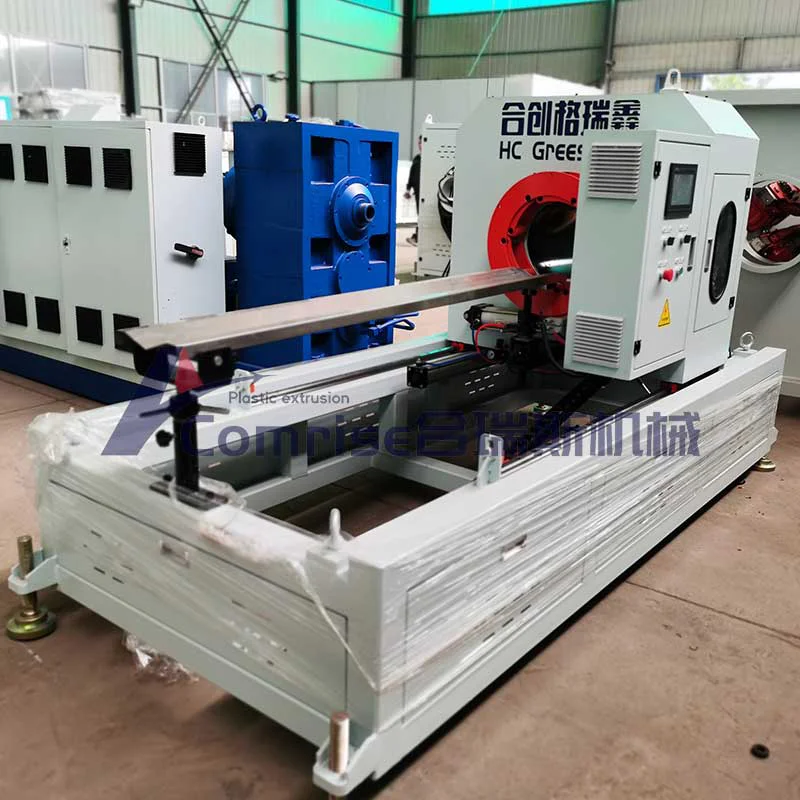

China PP Co-extruded Hollow Building Formwork Production Line Manufacturer, Supplier, Factory

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for PP Co-extruded Hollow Building Formwork Production Line,PP Hollow Corrugated Board Extrusion Machine,PP Hollow Board Machine,The Manufacture Hollow Building Formwork Making Machine,Equipment for Hollow Building Formwork Production, The continual availability of substantial grade goods in combination with our exceptional pre- and after-sales support ensures strong competitiveness in an increasingly globalized marketplace.

PP Co-extruded Hollow Building Formwork Production Line, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have a pleasant and long terms business together!!!

Hot Products

PVC Pipe Production Line

Comrise Machinery is a professional manufacture for 16-800mm PVC Pipe Production Line and supplier for PVC Pipe Machine in China. The 2024 newest PVC Pipe Production Line including 65/132 or 80/156 or 92/188 conical double screw extruder, pvc pipe molds, vacuum water tank, hall off machine, no dust cutter machine and auto discharger, high speed mixer, and further recycling machines like pvc pulverizer milling machine, crushing machine etc. The high quality PVC Pipe Production Line can use pvc powder with different formular to achieve raw material cost control, and achieve different pipe pressure requirements.Double Wall Corrugated Pipe Production machine

Comrise china factory supply Double Wall Corrugated Pipe Production machine 40-200mm Double Wall Corrugated Pipe machine 1. The host adopts a dedicated high-efficiency screw designed specifically for high-density polyethylene (HDPE), which has the characteristics of stable performance and high efficiency. This machine is equipped with two independent extruders, which can be used for practical applications Currently, different materials and colors are used for the inner and outer layers. 2. The composite extrusion mold adopts a special spiral structure to achieve uniform wall thickness and stable production. 3. The corrugated forming system combines water and air cooling to ensure high production speed.Double Wall Corrugated Pipe Machine

Comrise mainly producing HDPE Double Wall Corrugated Pipe Machine, prestressed plastic corrugated pipe equipment, PE carbon spiral pipe equipment, COD pipe equipment, MPP single-wall reinforced corrugated pipe equipment, PE gas pipe equipment, water seepage pipe equipment, medical-specific PVC tracheal intubation equipment, PPR pipe equipment , PE, PVC single-wall corrugated pipe equipment, plastic steel door and window profile equipment, gusset equipment, large-diameter winding pipe equipment, acrylic rod equipment, nylon pipe equipment, PE, PVC plates, sheets, PVC profile equipment, etc. Because of its novel products, superb technology, stable quality of pipes and high efficiency, it is widely praised by customers.Composite Decking Profile Machine

Comrise Machinery is a professional manufacturer of PE WPC wood-plastic composite decking profile machines. We offer comprehensive solutions, including all processes from raw materials to finished products, to produce high-quality, environmentally friendly, and durable composite flooring. Comrise PE WPC wood-plastic composite decking profile machine use advanced technology to achieve high productivity and efficiency while keeping operating costs low. Comrise also provide comprehensive technical support and after-sales service, ensuring that our clients can operate our equipment with ease and minimize downtime. Comrsie PE WPC wood-plastic composite decking profile machines can be customized to meet the specific needs of our clients. Comrise are known for our high-quality products and services, ensuring the complete satisfaction of our clients. If you're searching for a reliable and efficient manufacturer of PE WPC wood-plastic composite decking profile machines, look no further than Comrise Machinery.Pe Spiral Winding Pipe Machine

COMRISE specialize in providing advanced pe spiral winding pipe machine machinery for underground sewage construction or building usage. Comrise pe spiral winding pipe machine are used to create a variety of pipe types for different applications, such as hollow wall spiral winding, inner rib spiral winding, smooth wall winding, double plastic winding, and plastic insert steel winding. Comrise take pride in our expertise when it comes to larger diameter pipe machines, as it requires not only specialized machinery but also highly skilled professionals to operate them.UPVC PVC Window and Door Profile Machine

Comrise Machinery is a leading supplier of UPVC PVC window and door profile machines. Comrise machinery has been in the industry for over decades, and has established a reputation for providing high-quality machines and exceptional customer service.