China PP Hollow Board Machine Manufacturer, Supplier, Factory

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm for the long-term to create jointly with consumers for mutual reciprocity and mutual reward for PP Hollow Board Machine,PP Hollow Corrugated Board Extrusion Machine,PP Co-extruded Hollow Building Formwork Production Line,The Manufacture Hollow Building Formwork Making Machine,Equipment for Hollow Building Formwork Production, Being a young escalating company, we might not the top, but we're trying our best to generally be your superior partner.

PP Hollow Board Machine, We provide good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We are going to produce the items according to your request. If you are interested in any items we offer, please feel free to contact us directly by mail, fax, telephone or internet. We've been here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

Hot Products

ABC HDPE Pipe Machine

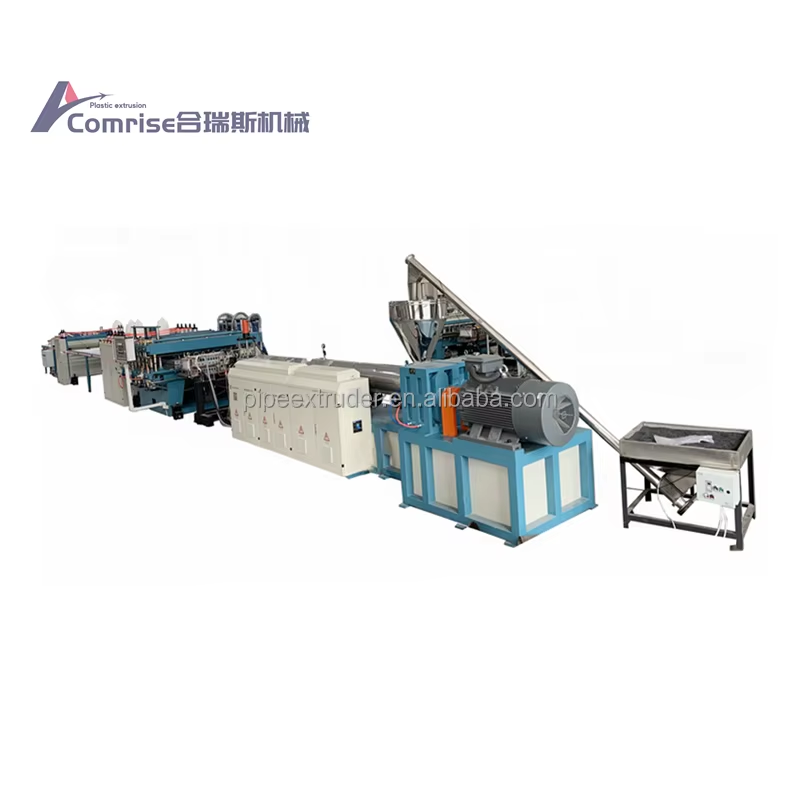

Comrise is a professional ABC HDPE Pipe Machine manufacturer and supplier in China. Comrise specialized in the manufacturing of high-quality plastic extrusion equipment, including plastic pipe, sheet and profile equipment, as well as plastic winding pipe equipment. With over 20 years of experience in the industry, COMRISE has a mature and professional team of engineers and customer service representatives. Comrise company dedicate to provide top-of-the-line products and services, with strict quality control measures, We look forward to working with you to move the plastic extrusion equipment industry forward.Industrial Water Chiller

Comrise Machinery is a leading supplier of industrial water chillers in China, providing solutions for cooling manufacturing processes and data center cooling. At Comrise Machinery, we are committed to providing our customers with the highest quality products and services. Comrise team of experienced technicians and engineers provides comprehensive technical support and customized solutions to meet the specific needs of their clients to ensure their satisfaction.Plastic Expansion Corrugated Pipe Production Line

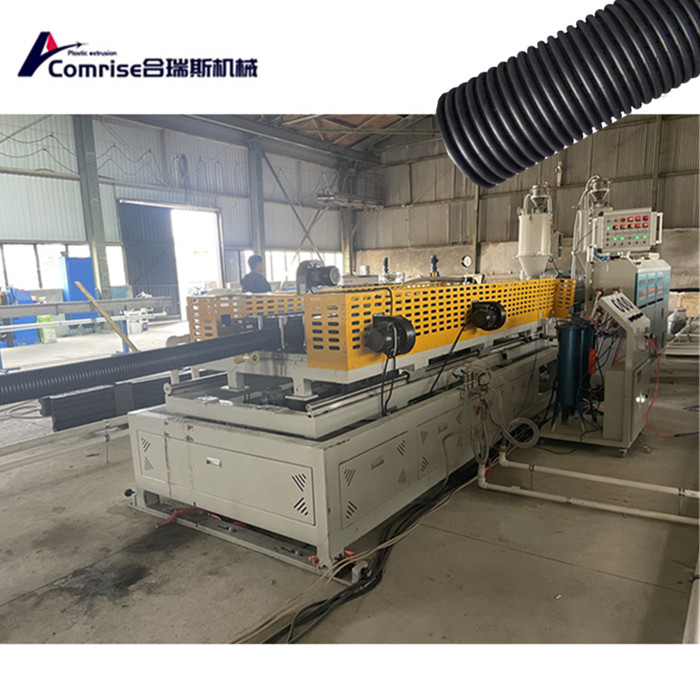

Characteristics and Applications of Plastic Expansion Bellows Production Line The single wall corrugated pipe machine developed by our company adopts gear operation modules and templates to achieve water circulation cooling and air cooling of the product, ensuring high-speed forming, uniform ripples, and smooth inner and outer pipe walls.Plastic Expansion Corrugated Pipe Production Line These corrugated pipes are particularly used for wire conduits. It is mainly used for producing PVC PP. PE is the raw material for small-diameter single wall corrugated pipes. Form homogeneous single-walled corrugated pipe products through corresponding molds. Wire and cable conduit, cleaning machine drainage pipe, vacuum cleaner, ventilation pipe, prestressed concrete special pipe.MPP Pipe Machine

Comrise manufacture 75-250 MPP pipe machine is mainly used for producing modified polypropylene cable conduits, using MPP special screws and high torque gearboxes. The extrusion die head adopts a special wheel design, and the vacuum cooling tank adopts frequency conversion control. The multi track tractor is driven by servo. The production line is also equipped with a high-speed self centering chip free cutting machine and a high-precision meter weight control system. The entire production line is highly automated, energy-saving and efficient.Good Qulaity Double Wall Corrugated Pipe Machine

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, PE large-diameter hollow-wall winding pipe production line, Good Qulaity Double Wall Corrugated Pipe Machine, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line, the plastic coated corrugated pipe production line, PE black jacket insulation pipe production line and PE sheet/board production line. HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.PP/PS Blister Packaging Sheet Production Line

Comrise machinery co.,ltd is a leading supplier for PP/PS Blister Packaging Sheet Production Line and China top manufacture for PP/PS Blister Packaging Sheet Production Line. The high quality plastic PP/PS Blister Packaging Sheet Production Line produced sheets after further processing are mainly used for hard packaging of fruits, vegetables, and food, outer packaging of cosmetics, hardware tools, children's toys, and containers for agricultural planting and seedling cultivation.