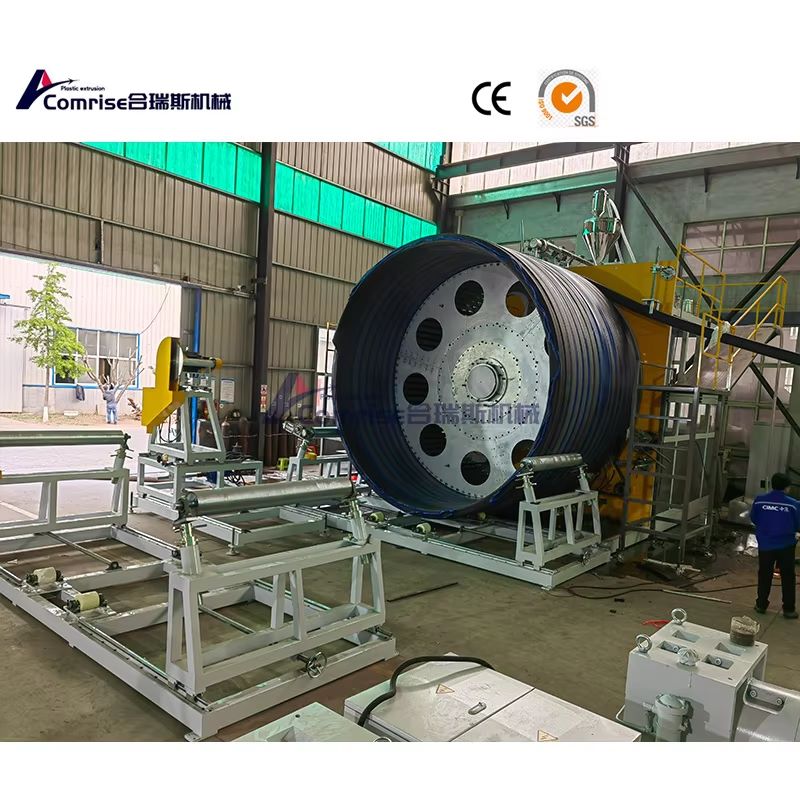

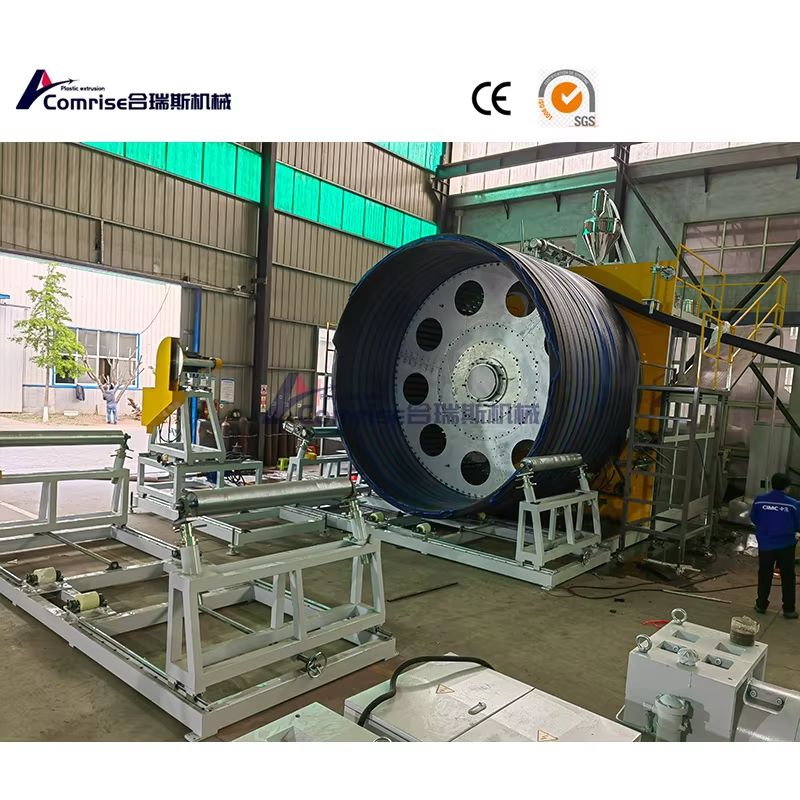

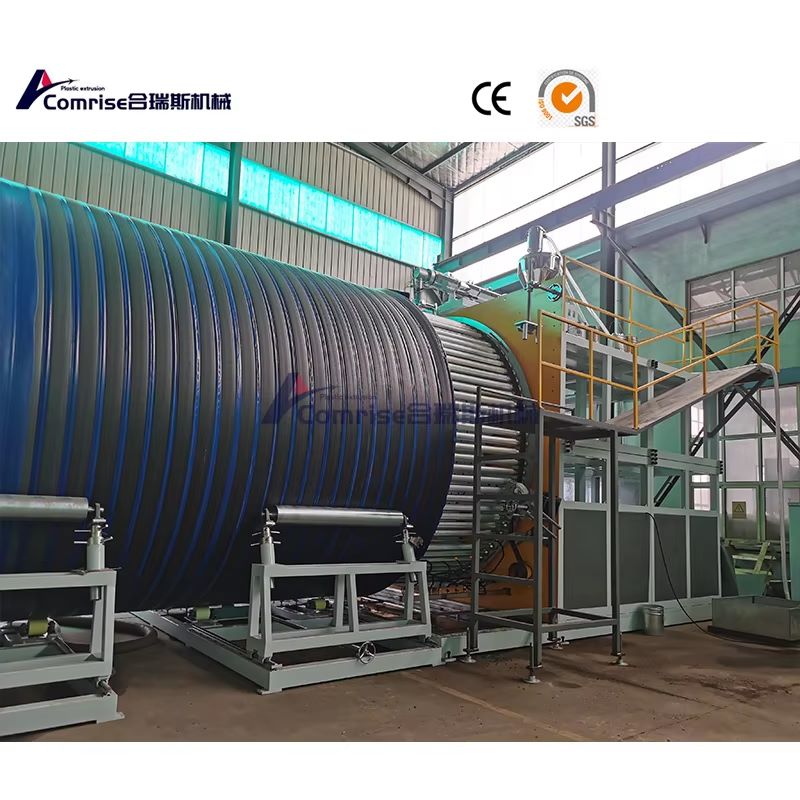

Hollow Wall Winding Pipe Production Line

Send Inquiry

Production line composition:

Hollow Wall Winding Pipe Production Line Extruder, mold, winding machine and forming mold, melt extruder, vacuum glue system, spray water tank, cutting machine, unloading platform and production control system that all we manufactuer.

The main features of this production line are:

1.Hollow Wall Winding Pipe Production Line Extruders have advantages such as high plasticization rate, uniform melting, and stable continuous production. High performance gearbox reducer. High torque, long service life, and low noise.

2. Surface nitriding, after nitriding, the product has excellent wear resistance, fatigue resistance, corrosion resistance, high temperature resistance, and long service life.

3. All parts are from well-known domestic and foreign brands.

Characteristics and uses of the products produced:

The surface area of the pipe is large, forming the same compressive strength as the pipe soil. The welding effect is good, and the tensile strength of the weld seam is enhanced. The internal reinforcement structure is beneficial for improving the stability of the ring stiffness.

Corrosive sewage pipelines in industries such as seawater, industry, chemical plants, and pharmaceutical factories;

Old city renovation, rainwater and sewage diversion project, sewage treatment plant, garbage treatment plant drainage;

Large scale projects such as municipal and construction engineering buried drainage, power plants, etc;

Agricultural irrigation and drainage;

Hollow wall winding pipe production line

**The Hollow Wall Winding Pipe Production Line adopts advantageous technology design and has been improved based on long-term practical experience. The diameter range can be 200-4000 millimeters.

**Our machine has the characteristics of comfort and high cost-effectiveness.

**Due to our special design, it is very convenient for transportation and installation.

**We have also developed energy-saving methods to save energy consumption during the extrusion of large-diameter hollow wall winding pipes.

**Using two sets of efficient extruders, with a large output. Our winding tube extrusion production line can manufacture pipes with ring stiffness of 4, 8, 12, and 16KN/m2. All components have been precisely designed and manufactured, ensuring stable and reliable operation of the entire extrusion production line.

**Specially designed and easy to maintain.

**The Hollow Wall Winding Pipe Production Line is mainly used for producing large-diameter hollow wall winding pipes and we can manufacture.

The complete production line consists of two parts:

1. The first part is the PE pipe extrusion line for extruding PE/PP square tubes (according to customer requirements).

Single screw extruder die head (mold and drill)

Calibration or

Vacuum calibration&c

Cooling water tank

Spray cooling tank

Traction machine

The second part is the spiral forming line forming and welding of large pipelines.

Single-screw extruder

Die head

Spiral forming unit

cutting machine

Knife holder

GET A QUOTATION NOW