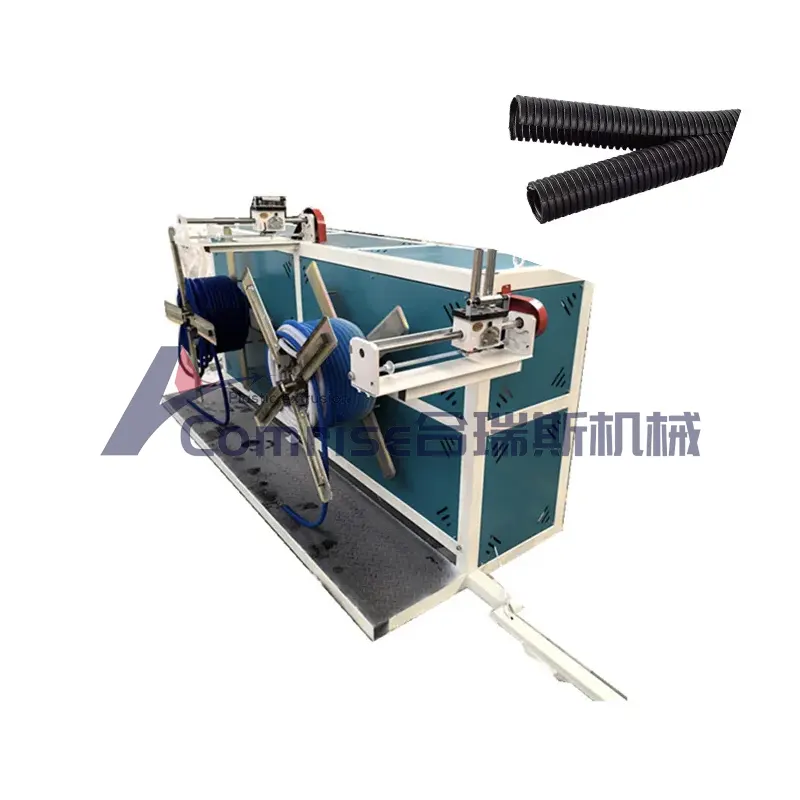

China Corrugated Pipe Forming Machine Manufacturer, Supplier, Factory

Our staff are generally while in the spirit of "continuous improvement and excellence", and while using the excellent high quality merchandise, favorable value and great after-sales services, we try to gain each customer's have faith in for Corrugated Pipe Forming Machine,Corrugated Tube Cutting Machine,Corrugated Pipe Extruder,Unicor Corrugator,Corrugated Flexible Pipe Machine, Adhering for the enterprise philosophy of 'customer initial, forge ahead', we sincerely welcome consumers from in the home and abroad to cooperate with us.

Corrugated Pipe Forming Machine, We have now established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Make sure you feel free to contact us for more details.

Hot Products

High Configuration and High-speed 20-110mm HDPE Pipe Machine

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. High configuration and high-speed 20-110mm HDPE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe productionPe Pipe Production Machine

The China Comrise is a professional factory offers excellent pe pipe production machine, with good after-sales service, ensuring that you are fully supported throughout the entire production process. Comrise team of experts is always ready to assist you with any questions or concerns you may have. So why wait? Upgrade your pe pipe production machine production line today with the China Comrise. Contact us now to learn more about our comprehensive range of extruder machines and related services.PP Pipe Manufacturing Machine

Comrise is China leading 315-630mm HDPE PP Pipe Manufacturing Machine supplier. We have been specialized in plastic extruder machinery field for 20+ years, and whole sale plastic pipe machine, plastic sheet machine, plastic board machine, plastic profile machine and auxiliary machine with good price and high quality. Our products have a good performance advantage and cover most of the European and Asian markets. We look forward to becoming your long-term business partner in China.Plastic Rigid Mesh Net Pipe Machine

Comrise Machinery is a professional manufacturer in China that specializes in the production of Plastic Rigid Mesh Net Pipe Machine and other plastic extrusion machinery. Comrise has over 20 more years of experience in the plastics industry and has a team of skilled and experienced professionals. Comrise Machinery follows strict quality control measures to ensure that all Plastic Rigid Mesh Net Pipe Machine meet the highest standards of performance and reliability. The Comrise Plastic Rigid Mesh Net Pipe Machines are designed to produce high-quality permeable pipes made of polyethylene (PE) material, which are widely used in drainage and flood control systems.COD Cable Communication Protection Tube Production Line

Qingdao COMRISE is a manufacturer of new COD Cable Communication Protection Tube Production Line, COD corrugated pipe machines, high-speed HDPE silicon core pipes, mechanical COD multi-channel fiber bundle pipe machine, new COD corrugated pipe machines, high-speed high-density polyethylene silicon core pipe machinery, and COD multi-channel fiber bundle pipe machines.PVC Profile Window Door Frame Extrusion Making Machine

Comrise PVC Profile Window Door Frame Extrusion Making Machine mainly composed by conical Twin Screw Extruder, Cooling Table, Hauling Machine, Cutting Machine, Stacker. With different moulds, it can produce various UPVC profile, such as: PVC window door profile,PVC Profile Window Door Frame Extrusion Making, PVC wall panel, PVC window sill board, cabinet door board, curtain box, PVC trucking, cable duct, PVC skirting, PVC protection corner and so on.we are plastic machine supplier