What Is The Best Blister Sheet Machine For Small Batch Production

2025-09-28

I have been in the packaging industry for over two decades, and if I have heard one question more than any other in recent years, it is this one What is the best Blister Sheet Machine for small batch production. It is a challenge that keeps many plant managers and business owners awake at night. The demand for flexibility has skyrocketed. Companies are dealing with shorter product lifecycles, personalized medications, niche consumer goods, and pilot runs for new products. The traditional, high-volume Blister Sheet Machine simply is not built for this new reality. It is like using a sledgehammer to crack a nut – inefficient, wasteful, and expensive.

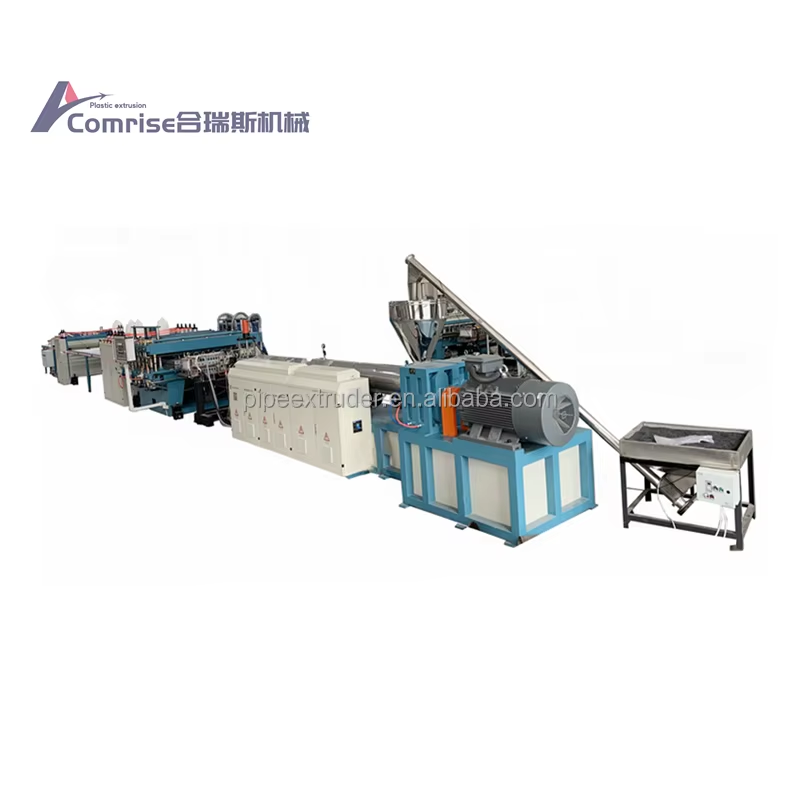

At Comrise, we have spent years specializing in engineering packaging solutions that are both powerful and precise. We understand that the heart of modern, agile manufacturing lies in having the right equipment. This is not just about selling a machine; it is about providing a strategic asset that enables your business to respond to market changes quickly and profitably. So, let us dive into what truly makes a Blister Sheet Machine ideal for the critical task of small batch production.

What Are The Biggest Challenges With Standard Blister Sheet Machines For Small Batches

When a pharmaceutical company or a contract packager approaches us struggling with their small batch efficiency, the problems are almost always the same. They have often invested in a machine designed for marathon runs, only to find it cripplingly inefficient for the short sprints that now dominate their schedule. The core issue is a fundamental mismatch.

The primary pain points we consistently observe include

-

Excessive Material Waste The setup and calibration process for a large machine can consume a staggering amount of forming film and lidding material before the first acceptable blister is even produced. For a batch of thousands, this waste is a manageable overhead. For a batch of hundreds, it can completely erase any potential profit margin.

-

Prolonged Changeover Times Switching from one product format to another on a standard machine can take hours. This involves changing forming molds, sealing dies, cutting tools, and recalibrating every parameter. This downtime is not just lost production time; it is hours of paid labor for skilled technicians with zero output, a direct hit to your operational efficiency.

-

Unsustainable Capital Cost Investing in a high-speed, fully automated Blister Sheet Machine capable of 300 cycles per minute is a massive financial commitment. The return on investment for such a machine is calculated on its ability to run 24/7. If it sits idle for a significant portion of the week waiting for the next small batch, the ROI calculation falls apart, making it a poor financial decision.

-

Lack of Flexibility These machines are often designed for a specific range of blister sizes and card styles. When a client requests a slightly different packaging format or a new, irregularly shaped product is introduced, the existing machine may be incapable of accommodating it without prohibitively expensive retrofitting or new tooling.

The bottom line is that using a standard machine for small batches turns your packaging line from a profit center into a cost center. The search for a better way begins with understanding these challenges intimately.

What Defines The Ideal Blister Sheet Machine For Small Batch Flexibility

So if a standard machine is not the answer, what is. The ideal Blister Sheet Machine for small batch production is not merely a smaller version of its high-volume counterpart. It is a machine built with a different philosophy at its core – one of agility, precision, and smart economics. After evaluating countless scenarios with our clients at Comrise, we have identified several non-negotiable features.

The machine must be modular. A modular design allows for basic initial configuration that can be expanded as your needs grow. You might start with a simple thermoforming and sealing system and later add integrated vision inspection, automatic reject stations, or specialized printing units. This protects your investment and ensures the machine evolves with your business.

Secondly, rapid changeover is not just a feature; it is the defining characteristic. We are talking about changeovers measured in minutes, not hours. This is achieved through clever engineering like tool-less adjustments, quick-release clamps for molds and dies, and digital recipe storage. An operator should be able to recall a product recipe from the touchscreen HMI, make a few simple physical adjustments, and be ready for production with minimal waste.

Finally, the machine must offer scalability and user-friendly operation. It should be operable without the need for a team of highly specialized engineers. Intuitive controls, clear diagnostics, and robust service support are essential. The goal is to empower your existing team to achieve maximum productivity with minimal downtime.

The table below contrasts the typical attributes of a standard machine against the ideal profile for small batch work

| Feature | Standard High-Volume Machine | Ideal Small Batch Machine |

|---|---|---|

| Changeover Time | Several hours, requiring technical staff | Less than 30 minutes, achievable by line operators |

| Minimum Economical Batch Size | Very high (10,000+ units) | Very low (100-500 units) |

| Flexibility | Limited to predefined formats and materials | High, with adjustable parameters for diverse shapes/sizes |

| Operator Skill Level | Requires highly trained technicians | Designed for ease-of-use with intuitive guides |

| Upfront Investment | Very high | Moderate, with a clear and fast ROI for small batches |

What Technical Specifications Should You Focus On In A Comrise Blister Sheet Machine

When you are evaluating a specific machine, the datasheet can be overwhelming. It is easy to get lost in a sea of numbers. Based on our experience at Comrise, here are the key parameters you should scrutinize when selecting a Blister Sheet Machine for small batch production. These specs directly impact the agility and efficiency we have been discussing.

Our flagship solution for this market segment, the Comrise AgileCell-S, is engineered precisely against these criteria. Let us break down its core specifications in a clear table format to illustrate what truly matters.

| Parameter | Comrise AgileCell-S Specification | Why This Matters for Small Batches |

|---|---|---|

| Production Speed Range | 10 - 60 cycles per minute (adjustable) | Allows for slow, precise runs for miniature batches and faster operation for slightly larger ones, preventing unnecessary speed that leads to waste. |

| Quick Changeover System | Tool-less adjustment with digital recipe storage (>50 recipes) | Cuts changeover time to under 20 minutes. Operators simply select the product on the HMI, follow guided prompts for adjustments, and start production with minimal material waste. |

| Max Sheet Size | 300mm x 200mm | A versatile size that accommodates a wide range of blister card layouts without being so large that it becomes inefficient for small formats. |

| Forming Depth | Up to 25mm | Sufficient for deep-draw blisters required for medical devices or large tablets, ensuring flexibility across product types. |

| Heating System | Zoned ceramic heating with precise digital control | Provides uniform heat distribution for consistent forming across different material types (PVC, Aclar, APET) and reduces energy consumption during idle periods. |

| Sealing Pressure | Programmable, from 1 to 5 bar | Allows perfect sealing for a variety of lidding materials, including sensitive aluminum foils for pharmaceutical applications. |

| Integrated Inspection | Optional 100% vision system for blister cavity fill and seal integrity | Critical for pharmaceutical compliance. Catches defects early in the small batch, saving the entire batch from rejection and ensuring patient safety. |

| Control System | Industrial PC with 15-inch touchscreen HMI | Provides a simple, intuitive interface for operators to manage all machine functions, track production data, and perform diagnostics. |

These specifications demonstrate that the Comrise AgileCell-S is not about brute force and maximum speed. It is about precision, control, and adaptability. Every parameter is chosen to minimize the cost-per-batch for short runs, making it a truly strategic investment for modern manufacturers.

Your Blister Sheet Machine FAQ Answered

Even with detailed specifications, we find our clients have very practical questions. Here are some of the most frequent questions we receive about implementing a Blister Sheet Machine for small batch production.

What is the typical ROI for a specialized small batch Blister Sheet Machine

The return on investment is surprisingly fast, often within 12-18 months for businesses heavily engaged in small batch work. The savings are not just in reduced material waste during changeovers. The significant reduction in downtime means you can pack more, different products into your schedule, increasing overall facility throughput. Furthermore, the ability to accept profitable small-batch contracts that were previously uneconomical opens up new revenue streams. When you calculate the ROI, you must factor in these hidden costs of your current system and the new opportunities a flexible machine provides.

Can the Comrise AgileCell-S handle different types of packaging materials like Alu-Alu

Absolutely. The Comrise AgileCell-S is designed with material flexibility in mind. Its zoned heating system and programmable sealing pressure allow it to work efficiently with a wide range of forming and lidding materials. This includes standard PVC/PVDC films, high-barrier materials like Aclar, and also aluminum-based laminates for both cold-forming and thermoforming Alu-Alu applications. The quick-change system extends to the forming and sealing stations, allowing you to switch between material types with minimal hassle, making it a truly versatile Blister Sheet Machine for diverse product requirements.

What kind of training and support does Comrise provide with the machine

We believe the machine is only as good as the support behind it. Comrise provides comprehensive onboarding that includes detailed operator and maintenance training at your facility, conducted by our expert engineers. We also offer extensive digital documentation and access to an online video library for ongoing reference. Our support package includes remote diagnostics capabilities, allowing our technicians to connect securely to the machine to help troubleshoot issues in real-time, minimizing downtime. We see ourselves as your long-term partner in packaging, not just a equipment supplier.

Are You Ready To Transform Your Small Batch Packaging Line

The question of finding the best Blister Sheet Machine for small batch production ultimately leads to a shift in mindset. It is about prioritizing flexibility and efficiency over raw speed. The Comrise AgileCell-S embodies this philosophy, offering the precision, rapid changeover, and user-friendly operation that can turn your small batch packaging from a logistical headache into a competitive advantage.

For over twenty years, I have seen how the right technology can transform businesses. It is not just about keeping up; it is about moving ahead. If you are tired of the waste, downtime, and inflexibility of your current setup, it is time to explore a solution designed for the way you work today.

Do not let your packaging equipment hold your business back. Contact us at Comrise today to schedule a personalized consultation and see how our AgileCell-S Blister Sheet Machine can be tailored to your specific small batch challenges. Our team is ready to discuss your needs, provide a detailed demonstration, and help you calculate the potential savings for your operation.