Call Us

+86-13780696467

Email Us

sales@qdcomrise.com

China Corrugated Pipe Cutting Machine Manufacturer, Supplier, Factory

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for Corrugated Pipe Cutting Machine,Corrugator Machine for Pipe,Corrugated Pipe Forming Machine,Corrugated Pipe Rolling Machine,Air Corrugated Pipe Machine, We welcome new and aged shoppers from all walks of daily life to call us for long term business associations and mutual accomplishment!

Corrugated Pipe Cutting Machine, What You Need Is What We Pursue.We are sure our products will bring you first class quality.And now sincerely hope to promote partner friendship with you from all over the world. Let's joint hands to cooperate with mutual benefits!

Hot Products

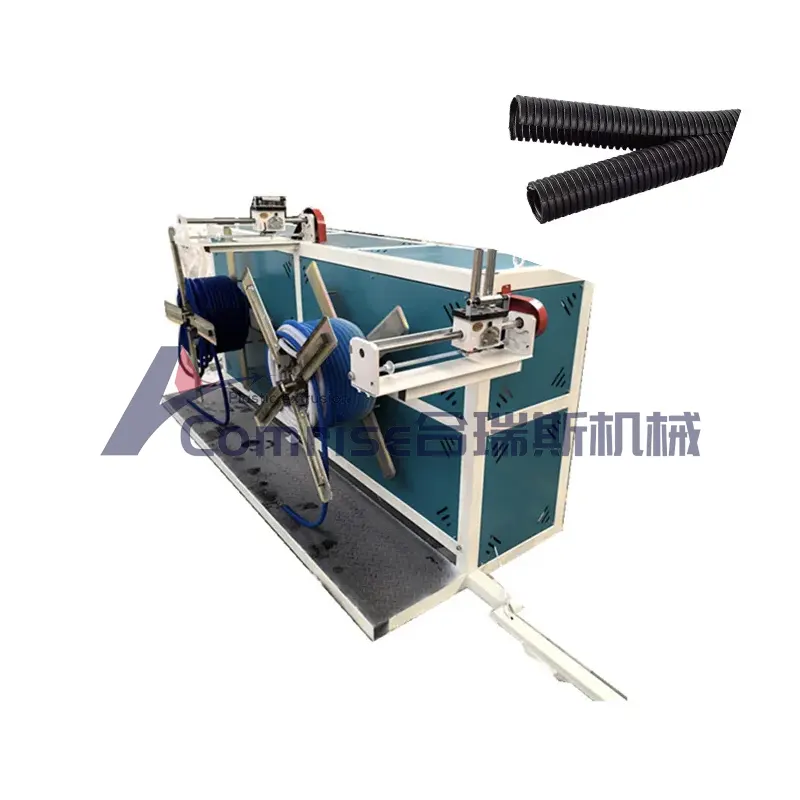

Single Wall Corrugated Pipe Machine Line

Comrise china factory PVC PE single wall corrugated pipe machine line/extrusion production line adopts extrusion molding technology, which has the characteristics of reliable quality and high efficiency. Compared with other plastic pipe wall structures, double walled corrugated pipes have excellent wall properties The structural design, with its low weight, achieves lower production costs and improves market competitiveness. It is widely used in various fields to replace concrete pipes and iron pipes because of its excellent features, such as easy connection and installation of accessories, and reliable qualityHDPE Pipe Mold

HDPE pipe mold produced by comrise machinery which is a professional manufacture factory and China supplier is an essential component used in the production of polyethylene (PE) pipes. China comrise has over 20 years of experience in the industry, a mature and professional team of engineers and customer service representatives. Comrise machinery are dedicated to providing top-quality products and services, with strict quality control measures throughout the development, production, testing, and after-sales processes.Efficient PVC Pipe Production Line

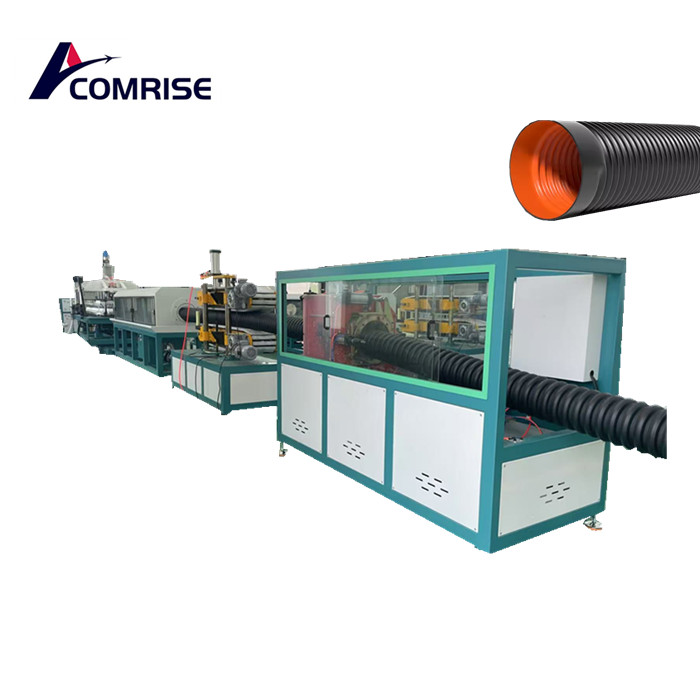

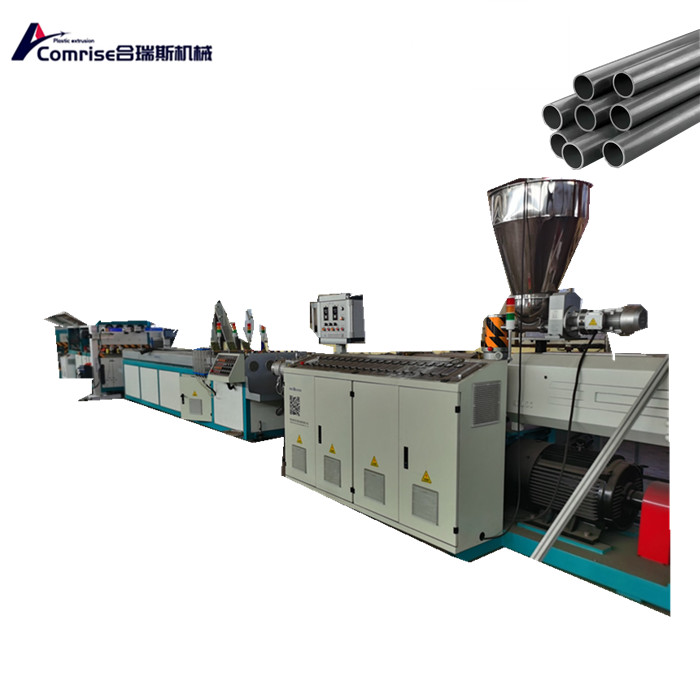

QINGDAO COMRISE MACHINERY main production line including high-efficiency PE water supply pipe production line, PE large-diameter hollow-wall winding pipe production line,Hollow wall winding pipe production line PPR cold and hot water supply pipe production line, Efficient PVC pipe production line,the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line , the plastic coated corrugated pipe production line,PE black jacket insulation pipe production line and PE sheet/board production line, . HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.PVC PE Single Double Wall Corrugated Pipe Production Line

Comrise Machinery supplies high quality PVC PE single double wall corrugated pipe production line for drainage purposes. This PVC PE single double wall corrugated pipe production line is designed to produce pipes that can withstand harsh environmental conditions, ensuring maximum efficiency in drainage systems. These pipes are lightweight, durable, and resistant to UV rays and cracking.HDPE Pipe Machine Line

The comrise manufacture HDPE Pipe Machine Line is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. 20-50mm HDPE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe productionHollow Structural Wall Polyethylene Spiral Pipe Extrusion Line

COMRISE is a professional company that is dedicated to providing a series of larger diameter Hollow Structural Wall Polyethylene Spiral Pipe Extrusion Line for underground pipe sewage construction or building usage. Comrise offer a range of underground pipe machines that can create different types of pipes, each with its unique advantages. At COMRISE, we take pride in our commitment to producing high-quality machinery that is reliable, efficient, and long-lasting.

Related Search

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy