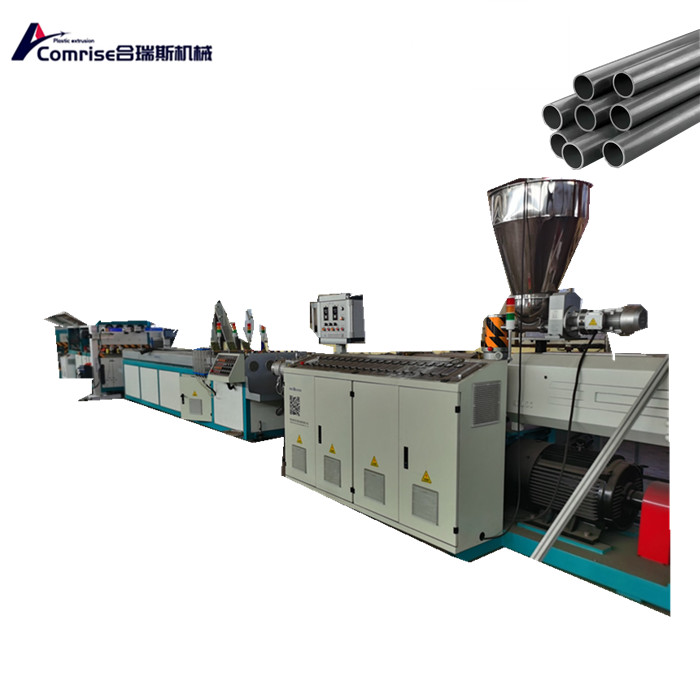

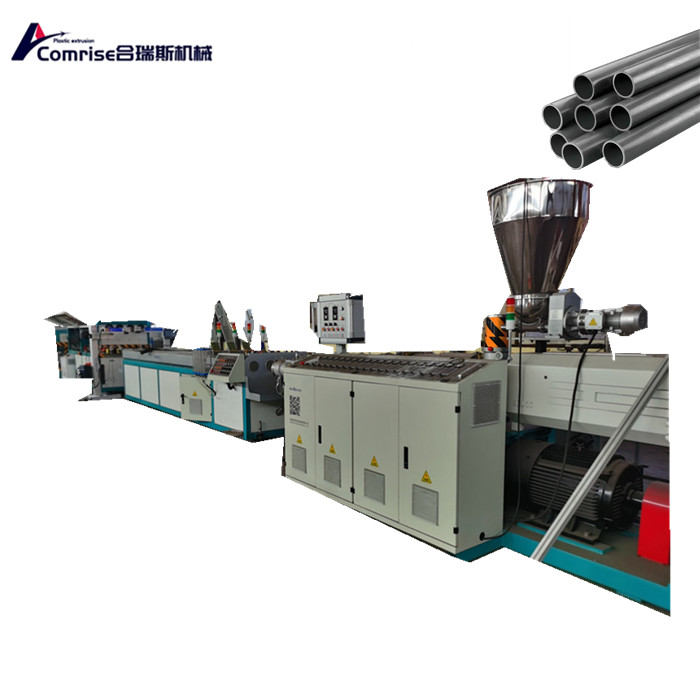

Efficient PVC Pipe Production Line

Send Inquiry

Advantage:

Efficient PVC pipe production line we manufacture.The series extruder is equipped with appropriate molds and auxiliary machines, which can directly convert thermoplastic, especially polyvinyl chloride powder, into pipes, sheets, films, and profiles, and provide modification and granulation functions. The extruder is equipped with a Derived from the C motor, it can be infinitely adjusted. It is also equipped with overload protection and shutdown alarm system. The core of the screw and the exterior of the barrel are cooled by oil circulation, including vacuum exhaust and forced feeding.

Application:

The Efficient PVC Pipe Production Line for PVC pipes with diameters ranging from 16mm to 800mm is mainly used to manufacture plastic PVC pipes of various diameters and wall thicknesses, which are used for agricultural and construction pipelines, cable laying, etc.

PVC pipes include the following parts:

Spring seat → Conical twin-screw extruder → Mold → Vacuum calibration tank → Dragging → Cutting tool → Wooden stake, etc.

The extruder and trailer are equipped with imported AC variable frequency speed regulation devices, while the vacuum pump and trailer motor are made of high-quality products.

The towing methods include two claws, three claws, four claws, and six claws.

You can choose between saw blade cutting type or planetary cutting type. It also comes with a length counter and enhancement device. The production line is reliable and has high production efficiency.we are china good machine supplier.

PVC One cavity Production Line

-One cavity pipe extrusion production line

TheEfficient PVC Pipe Production Line of the Φ 20- Φ 630 series PVC pipe extruder is mainly used to manufacture plastic PVC pipes of various diameters and wall thicknesses, which are used in industries such as agriculture and construction pipelines, cable laying, etc.

This line is transported by a conical twin-screw extruder, vacuum calibration tank, motor, cutting machine, and stacker crane. The extruder and towing methods include double claw, three claw, four claw, six claw, eight claw, ten claw, twelve claw, etc. You can choose between saw blade cutting type or planetary cutting type. It also comes with a length counter and enhancement device.

The production line is reliable and has high production efficiency. Our company can also manufacture special pipe production lines, such as spiral soundproof pipes and core foam pipes according to your requirements.

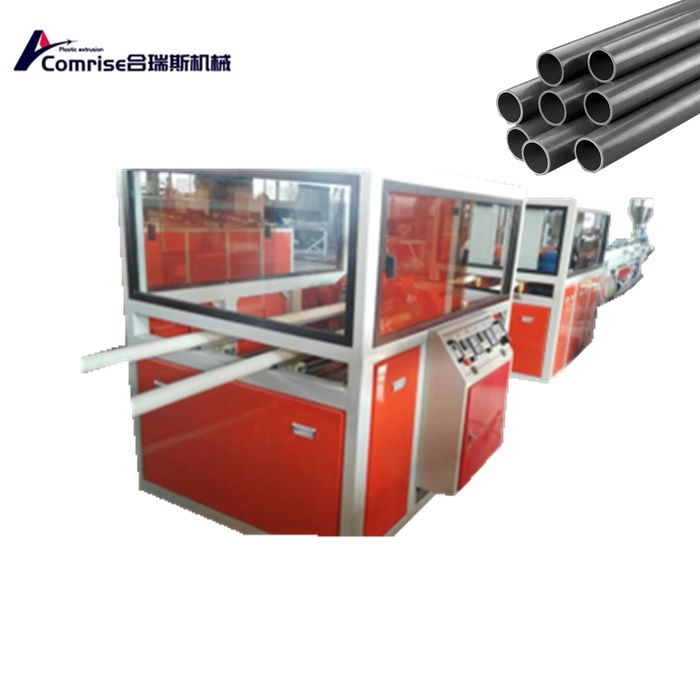

PVC Double Chamber Pipe Extrusion Production Line

PVC double pipe production line

-Double cavity PVC pipe extrusion production line

This production line was developed by our company using advanced technology from Western Europe.

The main machines are SJSZ55/120 or SJSZ65/132 conical twin-screw extruders equipped with double tube single control stainless steel spray calibration; When adjusting one pipe while the other pipe is affected, it avoids wastage.

The combination of automatic single control double wire drawing machine and cutting machine with front double calibration technology makes the operation more flexible, allowing you to enjoy the economic benefits brought by separate control double tube extrusion.

PVC four chamber tube extrusion machine line

PVC four cavity production line

-Four cavity PVC pipe extrusion production line

The four chamber PVC electrical and water supply Efficient PVC Pipe Production Line can simultaneously extrude four pipes on one machine.

This line can save investment costs in factory construction and production, significantly increasing capacity and reducing production time.

The Sjsz65 conical twin-screw extruder can easily reach 5.5-6.5 tons/day, and with a production speed of 16 millimeters as an example, more than8-10m/minute can be obtained.

The entire line consists of a 65mm conical twin-screw extruder, 4-cavity molds, 4-cavity cooling calibration tanks, 4-station towing, 4-station cutters, and 4-station flipping tables.

GET A QUOTATION NOW