Call Us

+86-13780696467

Email Us

sales@qdcomrise.com

China PP Sheet Extruder Machine Second Hand Manufacturer, Supplier, Factory

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for PP Sheet Extruder Machine Second Hand,PP Callender Sheet Machine,Pe pp Sheet Board Extruder Machine,PP Ps Pet Sheet Making Machine,Pe PP Roll Sheet Cutting Machine, We have experienced manufacturing facilities with more than 100 employees. So we can guarantee short lead time and quality assurance.

PP Sheet Extruder Machine Second Hand, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Hot Products

800-2000mm PE Hollow Wall Winding Pipe Machine

Comrise 800-2000mm PE Hollow wall winding pipe machine is a specialized extrusion production line designed for the manufacturing of large diameter hollow pipes made of high-density polyethylene (HDPE) material. 800-2000mm PE Hollow wall winding pipe machine can produce HDPE pipes with diameters ranging from 300mm to 1200mm, making it suitable for use in municipal and industrial drainage and sewage systems. The 800-2000mm PE Hollow wall winding pipe machine uses cutting-edge technology for precise temperature and speed control, ensuring uniformity and consistency in the production process. The resulting pipes are lightweight, durable, and resistant to impact and abrasion, making them ideal for various applications. The 800-2000mm PE Hollow wall winding pipe machine production speed ranges from 0.6m/min to 1.5m/min, with an output capacity of up to 600kg/h. Our company is committed to providing customers with high-quality products and services, backed by a team of experienced engineers and customer service representatives who are dedicated to meeting our customers' needs and exceeding their expectations.Corrugated Pipe Extrusion Machine

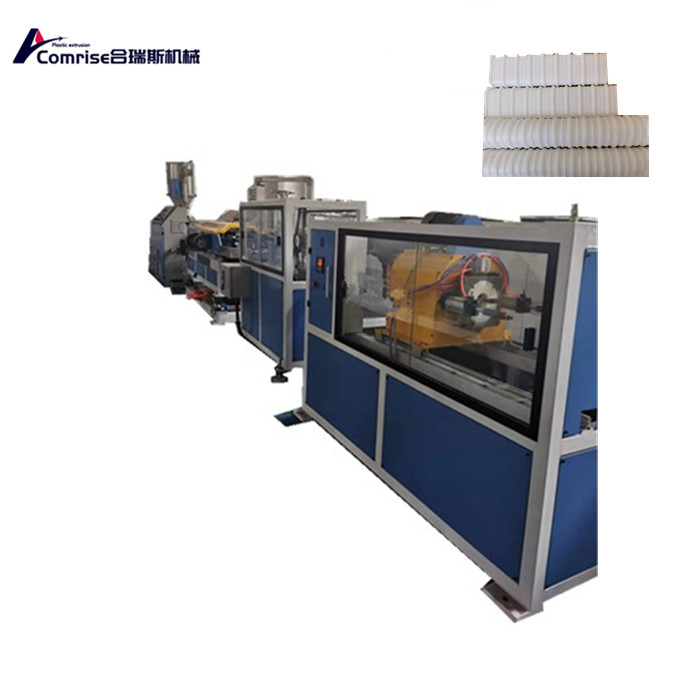

Comrise machinery Corrugated pipe extrusion machines are specialized equipment used to produce corrugated pipes, which have a wide range of applications depending on whether they are singlewall or doublewall corrugated pipes. Here's a breakdown of their differences and applications:1.SingleWall Corrugated Pipe Extrusion MachineSteel Belt Reinforced Spiral Pipe Production Line

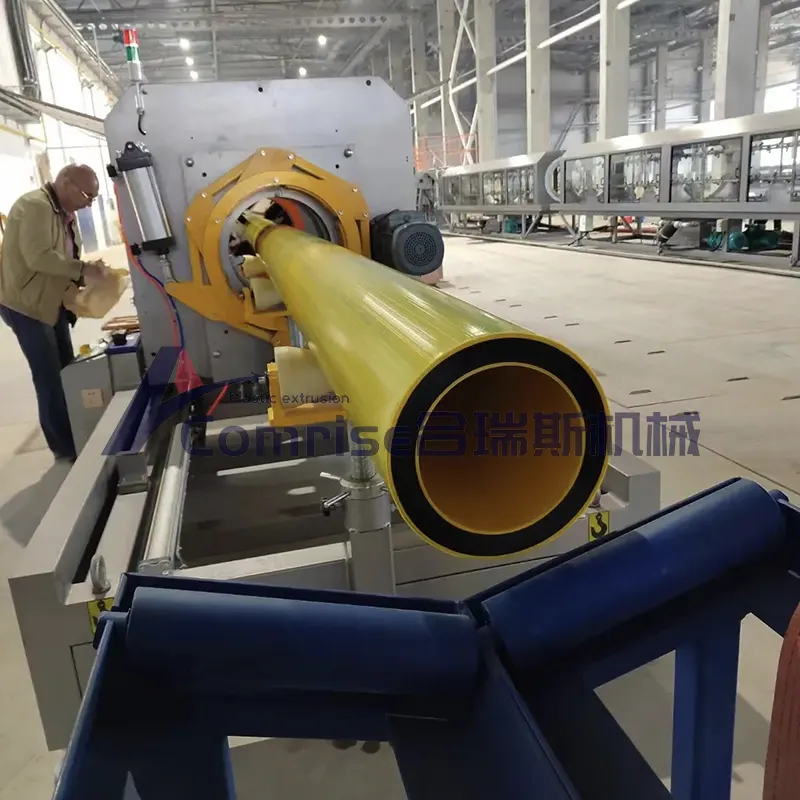

Comrise Machinery is a professional supplier and manufacture for Steel Belt Reinforced Spiral Pipe Production Line, the high quality Steel Belt Reinforced Spiral Pipe Production Line inlcuding four extruders for different usage, profile extrusion, glue extrusion, this newest Steel Belt Reinforced Spiral Pipe Production Line can make pipe diameter from 300mm to 1200mm which use mostly in the market with high stiffness.PE Foam Insulation Pipe Making Machine

Comrise is a team of passionate professionals that strives to provide the industry with the best plastic pe foam insulation pipe making machines worldwide. China manufacture Comrise team comprises some of the most experienced engineers and designers dedicated to building reliable and efficient pe foam insulation pipe making machine. Comrise dedication to meeting and exceeding customer satisfaction has earned us a solid reputation in the plastic machinery manufacturing industry.Double Wall Corrugated Pipe Making Machine

Comrise factory Double Wall Corrugated Pipe Making Machine is developed and manufactured by Comrise, using a molding machine template design. The product is air-cooled through a gear transmission module, with fast molding speed, uniform corrugated shape, consistent joints, and smooth inner and outer walls.110mm HDPE Pipe Machine

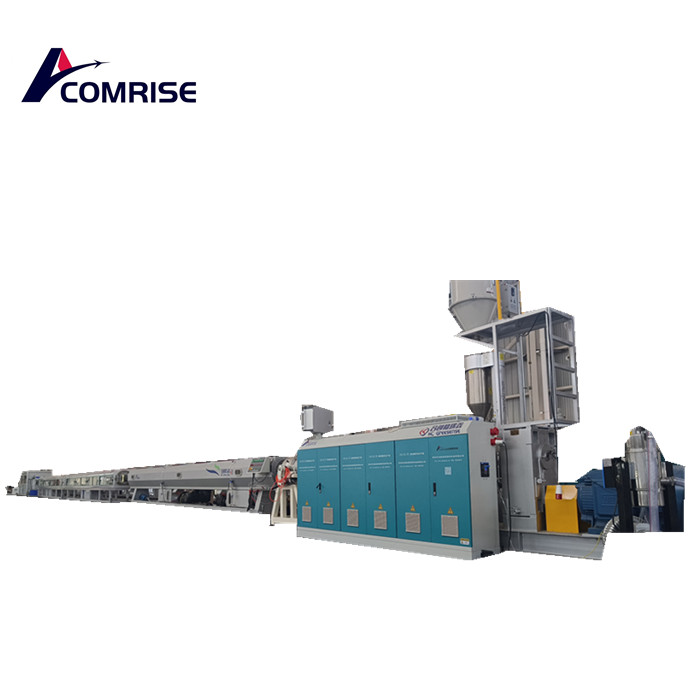

Comrise factory 110mm HDPE Pipe Machine machine Manfacture configuration is different as per produced pipe diameter range. For small diameter range like 20-63mm, there are several different speed models for option, the highest production speed is up to 60m/min for 20×2.0mm HDPE pipes. Big diameter HDPE pipe extrusion line can be designed as two layer co-extrusion type or 3 layer co-extrusion type. Pipe coiler is equipped as an option, to coil pipe size from 16-32mm, or 20-63mm or much big up to 110mm.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy