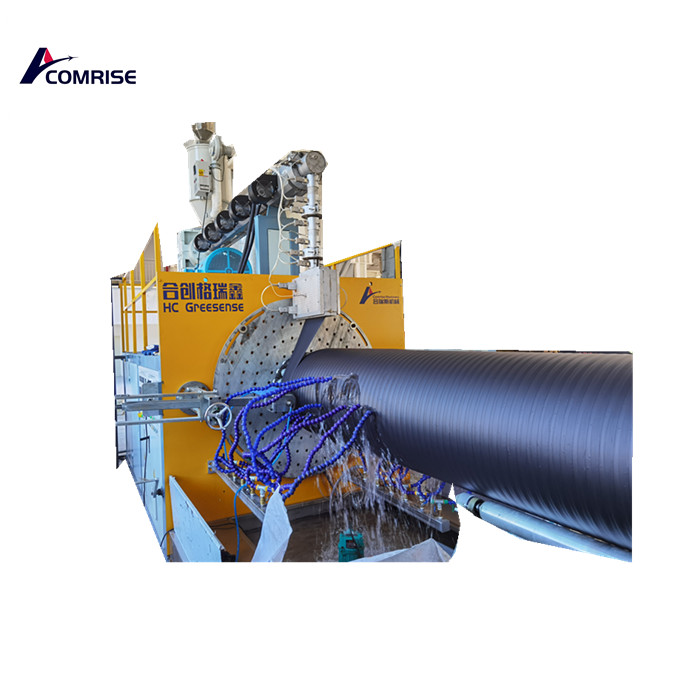

Steel Strip Winding Reinforced Pipe Machine

Send Inquiry

Application: Municipal engineering, water supply, drainage; Telecommunications project; Industrial projects:

Steel Strip Winding Reinforced Pipe Machine

Urban underground drainage and sewage pipelines.

Factories and sewage treatment plants

Drainage and sewage pipelines, ventilation system pipelines

Laying cable/optical cable sheath

The pipeline system for transporting seawater and rainwater

Water collection and seepage system

Agricultural irrigation pipeline

Manufacturing of chemical process containers

2. china factory comrise steel+HDPE drainage winding pipe production line:

The Steel Strip Winding Reinforced Pipe Machine single screw extruder and gearbox can ensure high production capacity and less energy. The use of PLC will greatly facilitate and improve the perfect combination of its semi automation. With our unique plastic steel composite technology, strip and pipe production can be carried out continuously and in one step. Steel can be perfectly mixed into plastic to prevent chemical corrosion from the outside. Compatible winding holders only require 2 wires to cover the production range of DN200-3000 and remain stable in large-diameter production we manufacture.

3. Equipment features:

1. Fast production speed

2. Wide production scope

3. Low defect rate

4. Continuous production

5. Requires less space

6. Labor costs

Steel reinforced polyethylene (PE) spiral corrugated pipe is a new type of corrugated pipe made of high-density polyethylene as the basic material can be supplier. The outer layer is spiral wound in the wall layer, and the steel plate is reinforced with hollow ribs. It not only has the corrosion resistance, smooth inner wall, and low flow resistance of ordinary plastic pipes, but also has a hollow enclosure structure with steel rings as steel bars, so it also has a ring degree of 12.5KN/m2 or more (spiral winding). Hollow wall polyethylene can only reach 8KN/m2 ring steel, with high strength, good toughness, light weight (40% lighter than spiral wound hollow wall polyethylene pipes), impact resistance, resistance to breakage, and no leakage. Due to its unique characteristics, it is widely used in fields such as drainage, sewage treatment, agricultural irrigation, coal mine ventilation, chemical engineering, and communication cable sheath. Due to its light weight, convenient transportation and installation, it reduces the labor intensity of construction personnel and lowers the project cost. It is an ideal substitute for concrete pipes and traditional plastic drainage pipes.

Steel strip reinforced PE spiral pipe

Characteristics of outer diameter: commonly used diameter 200mm~4000mm

Material: High quality, original or recycled PE100/PE80 we can manufacture

The ring stiffness reaches SN8 to SN16300 millimeters (12 inches) to 3200 millimeters (126 inches)

HDPE large-diameter hollow wall winding pipe machine.

**The Steel Strip Winding Reinforced Pipe Machine adopts advantageous technology design and has been improved based on long-term practical experience. The diameter range can be 200-3000 millimeters.

**Our Steel Strip Winding Reinforced Pipe Machine has the characteristics of comfort and high cost-effectiveness.

**Due to our special design, it is very convenient for transportation and installation.

**We have also developed energy-saving methods to save energy consumption during the extrusion of large-diameter hollow wall winding pipes.

**Using two sets of efficient extruders, with a large output. Our winding pipe extrusion production line can manufacture pipes with ring stiffness of 4, 8, and 12KN/m2. All components have been precisely designed and manufactured, ensuring stable and reliable operation of the entire extrusion production line.

**Specially designed and easy to maintain china top factory

**The HDPE large-diameter hollow wall winding pipe extrusion production line is mainly used for producing large-diameter hollow wall winding pipes.

GET A QUOTATION NOW