China Plastic Blind Ditch Rigid Mesh Net Pipe Machine Manufacturer, Supplier, Factory

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for Plastic Blind Ditch Rigid Mesh Net Pipe Machine,Blind Ditch Rigid Net Mesh Pipe Extrusion Line,Plastic Rigid Mesh Net Pipe Machine,Blind Ditch Rigid Mesh Net Pipe Machine,Pipe Filter Mesh Producing Machine, To acquire a consistent, profitable, and constant development by getting a aggressive advantage, and by continuously increasing the value added to our shareholders and our employee.

Plastic Blind Ditch Rigid Mesh Net Pipe Machine, we have now complete material production line, assembling line , quality control system, and the most importantly, we now have many patents technology and experienced technical&production team, expert sales service team. With all those advantages, we're about to create"the reputable international brand of nylon monofilaments", and spreading our solutions to every corner of the world. We've been keep moving and try our best to serve our customers.

Hot Products

PVC Pipe Production Line machine

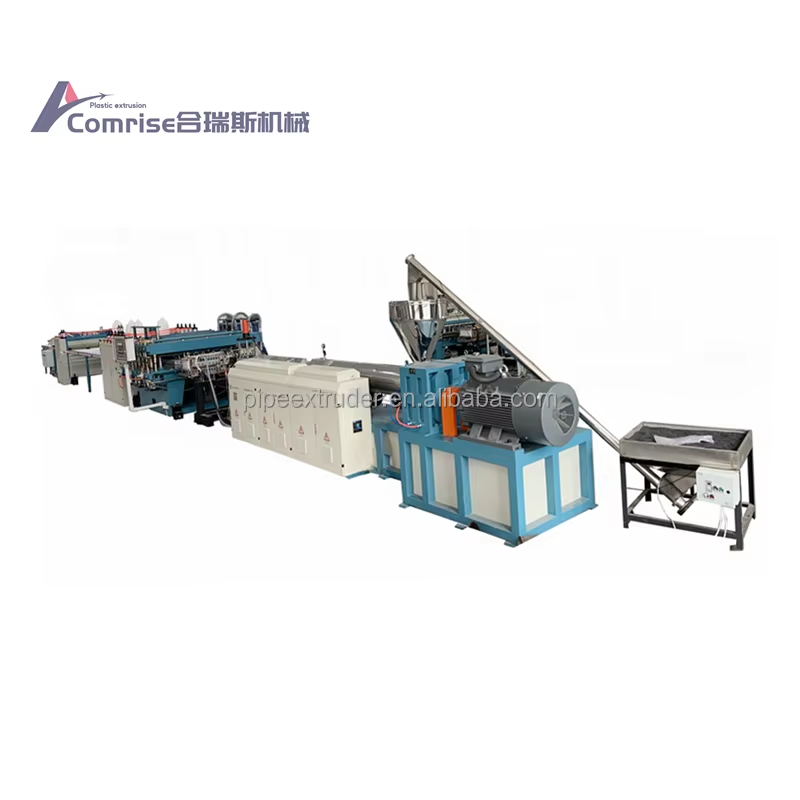

Comrise PVC pipe extrusion line includes conical twin screw extruder, spiral die head, vacuum tank, water tank, haul-off, no-dust cutter or planetary cutter, belling machine with O-ring sockets or rectangular sockets or U types of sockets.this machine supplier Our PVC pipe production line machine can make pipes ranging from 16-630mm PVC Pipe Machine, wall thickness range of 1-30mm.Hdpe Pipe Making Machine

The Hdpe Pipe Making Machine and PP gas water supply pipe production line produced by Comrise Machinery is mainly used for the production of agricultural water supply and drainage, building water supply and drainage, cable laying, and other aspects. Hdpe Pipe Making Machine consists of a vacuum qualitative table, a traction machine, a cutting machine, a flipping rack, etc. The single screw extruder and traction machine adopt imported variable frequency speed regulation devices, and the vacuum pump and traction motor are all high-quality products. The traction machine is equipped with two claw, three claw, four claw, six claw, eight claw, ten claw, twelve claw and other traction methods. You can choose chip free cutting, saw blade cutting or planetary cutting, and the unit has reliable performance and high production efficiency. Our company can produce Hdpe Pipe Making Machine,inner wall spiral tubes, inner wall hollow tubes, and core foam tubes with dedicated equipment according to user requirements. After replacing the extruder, we can produce PP, PE, ABS, PPR, PEX, Silicon core tube and other material pipes. The planetary cutting machine adopts fully automatic computer numerical control, which has the advantages of easy operation and reliable performancePE PPR Pipe Extrusion Production Line

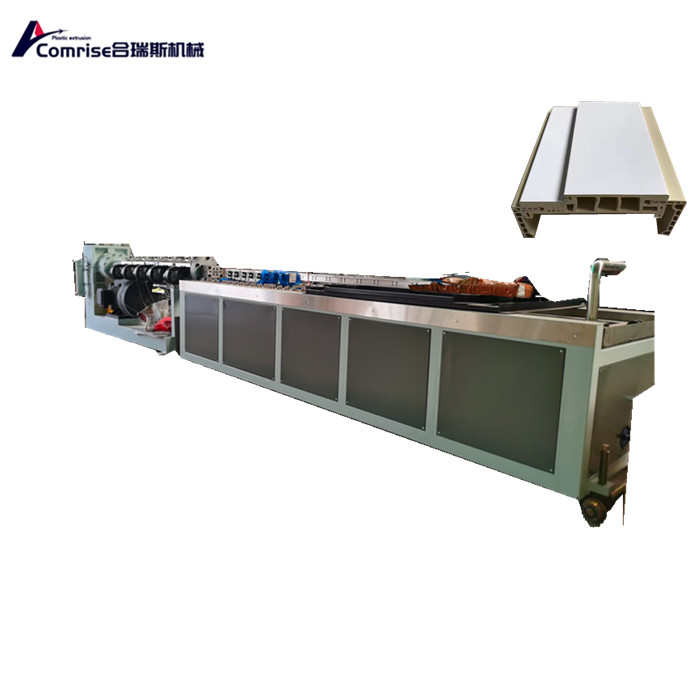

Comrise Machinery's PE PPR pipe extrusion production line is a game-changer in the piping industry. Its simplified production process, adaptable design, improved product quality, cost-effectiveness, and environmental sustainability make it the best choice for businesses looking to increase their profitability while making valuable contributions to society.PVC Door and window panel profile machine

The Comrise factory offer PVC Door and window panel profile machine mainly consists of a conical Twin S unit E extruder, a cooling T-type machine, a Hailing Machine, a Cutting Machine, and a Stacker Having different molds, we can produce various UPVC profiles, such as PVC window and door profiles, PVC wall panels, PVC window sills, cabinet door panels, curtain boxes, PVC trucks, cable conduits, PVC skirting boards, PVC protective corners, etc. And by replacing the screw barrel and mold, PVC based WPC products can also be produced, such as WPC wall panels and WPC windowsPlastic Sheet And Profile production Line

COEMRISE The board/sheet extrusion production line is a state-of-the-art manufacturing system designed to produce various plastic boards and sheets with excellent surface quality and dimensional stability. Plastic Pipe Sheet And Profile production Line,This production line supplier is very suitable for producing materials for various industries, including construction, packaging, automotive, and signage. Plastic Sheet And Profile production LineThe advanced technology of this production line ensures high precision and efficiency in producing standard and customized sheet products, including PVC, PS, PP, PE, and other thermoplastic materialsPVC Wood Plastic Door Production Line

Comrise Machinery is a Chinese supplier and factory of high quality PVC Wood plastic door production line. Comrise machinery offer comprehensive solutions, including all processes from raw materials to finished products, to produce high-quality, beautiful, and durable PVC wood plastic doors. Comrise newest PVC Wood plastic door production line use advanced technology to achieve high productivity and efficiency while keeping operating costs low. Comrise also provide comprehensive technical support and after-sales service, ensuring that our clients can operate our equipment with ease and minimize downtime. Comrise wholesale PVC Wood plastic door production line can be customized to meet the specific needs of our clients. Comrise is known for high-quality products and services, ensuring the complete satisfaction of our clients.