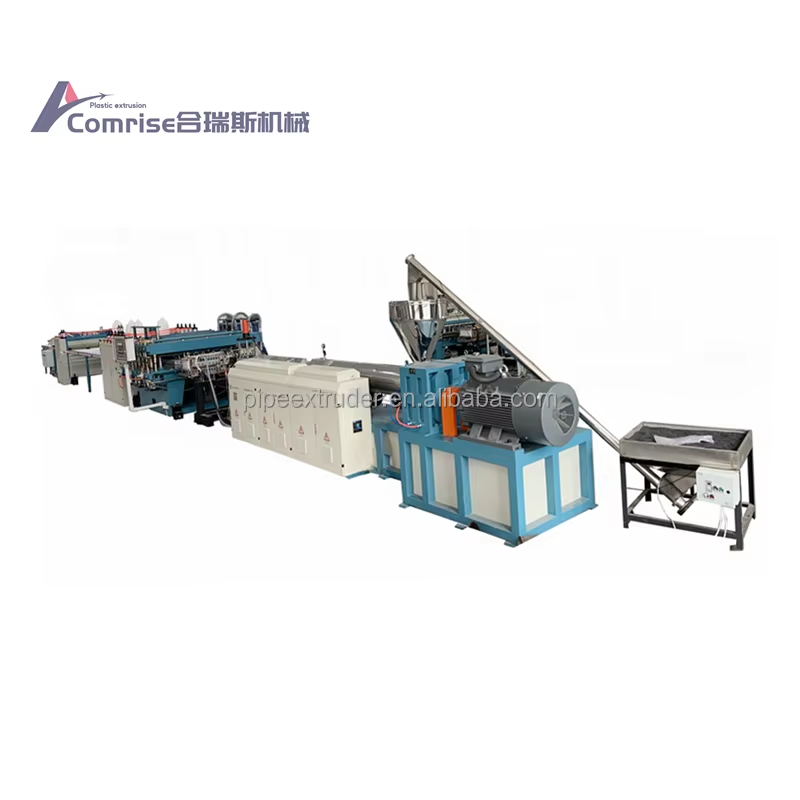

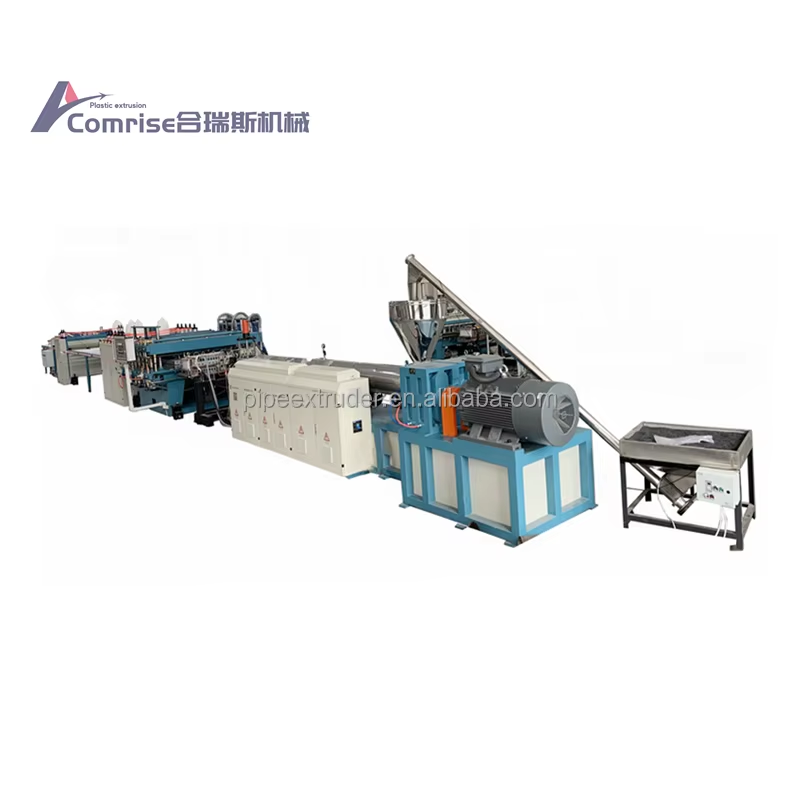

Plastic Sheet And Profile production Line

Send Inquiry

Comrise factory In order to meet the market demand for diversified and personalized plastic sheets, the manufacturing machine will have more functions and stronger adaptability. For example, develop a multifunctional composite sheet manufacturing machine that can simultaneously produce multi-layer composite sheets, two-color sheets, functional sheets, etc.; realize the integration of multiple processes such as extrusion, calendering, and stretching, and improve the versatility and flexibility of the equipment.As a complete solution provider for plastic sheet manufacturing machines, SHARC’s products include PVC sheet manufacturing machines, PET sheet manufacturing machines, ABS sheet manufacturing machines, PP/PE sheet manufacturing machines, PC sheet manufacturing machines, PLA sheet manufacturing machines and other plastic sheet production machines. It can meet the diverse production needs of customers.

Plastic Sheet And Profile production Line are resistant to impact, corrosion resistance, high heat resistance, non-toxic and tasteless, smooth surface appearance, low density, light weight, easy processing, good dimensional stability, rigidity, good heat resistance Will produce gas.

Application

· PP board: Widely used in chemical industry, food industry, anticorrosive industry, purification industry, environmental protection equipment manufacturing industry, etc.

· PE board: Widely used in chemical industry, electric power and other industries. Plastic Sheet And Profile production Line can also be used in machinery and chemical equipment as engineering plastics.

· ABS board: ABS skin-grain board, ABS inferior smooth leather grain board, flame retardant board, usually used for roof of cars/buses, car dashboard, window frame of cars, also for trip suitcases, bags, etc.

Extruder

Appropriate single-screw extruder (exhaust or not) or Parallel twin screws extruder, should be chosen on the basis of different materials. Specially designed screw and advanced temperature controlling system ensure the good plasticization, high output and stable extruding.

Hard screw and barrel, special structure design of screw for PP/PE material. 100% recycled material possible.

Whole-zone temperature monitoring, pressure monitoring.

Automatic material feeding system.

Control system

Intelligence, simpleness, stability, efficiency. Adopt SIEMENS S7-1500 controlling system, equipped with Siemens frequency, Siemens servo for drive part. Through the Profinet network link, the controlling system is more credible, stable and efficient.

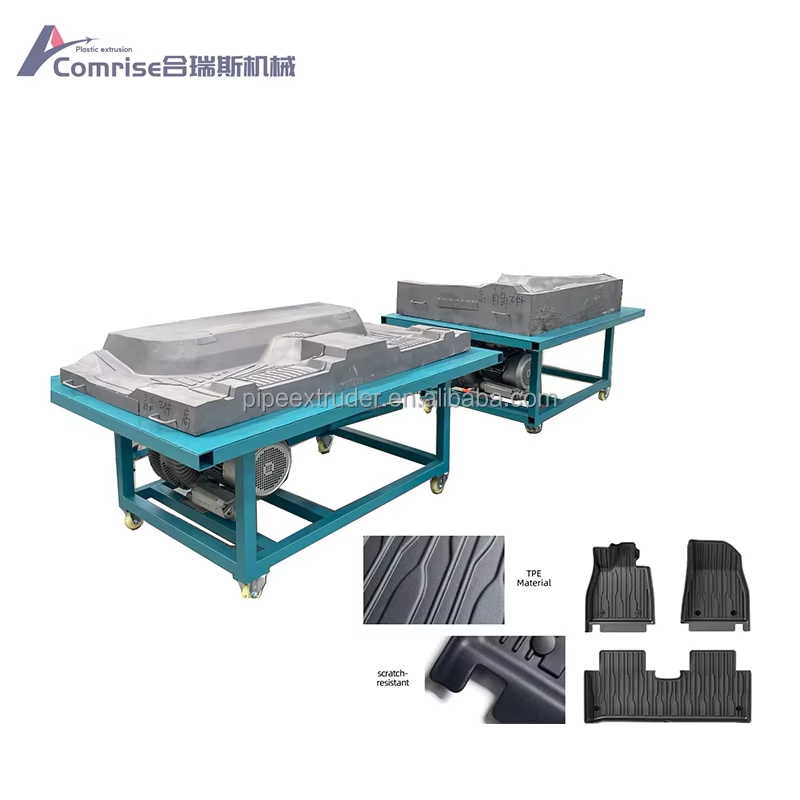

ABS PMMA GPPS HIPS Co-Extruder Sanitaryware Plastic Board Extruder Machine

ABS SHEET has very good mechanical properties, dimensional stability, processing ability, chemical resistance, and a high-quality appearance. These advantages make ABS resin an excellent engineering plastic.. It has been widely used in manufacturing machinery, electronic components, electrical and home appliances, auto parts, medical products, food and water contact materials, construction materials, toys and sporting goods, and cosmetics containers

Application Of ABS, HIPS refrigerator board: it can be divided into ABS plate, non-fluorin ABS plate, germproof ABS plate, HIPS plate, high luster composite HIPS plate. It has the good features of flexibility in low temperature, high impact, anti-erosion. The products used in gallbladder in the refrigerator, door gallbladder, the drawer, water contained plate, etc.

Application of ABS, car (baggage)board: it can be divided into veins plate, sub-veins plate, anti-flammable vein plate. The plate has the feature of good thermoplastic, anti-flammable and impact resistance. Widely used in top of the car and bus, instrument board, backrest, car door, windows frame, shell of the motorcycle, all kinds of baggage, etc.Plastic Sheet And Profile production Line