China Hollowness Wall Winding Pipe Extrusion Machinery Manufacturer, Supplier, Factory

We're convinced that with joint initiatives, the business between us will bring us mutual benefits. We can easily guarantee you merchandise good quality and competitive rate for Hollowness Wall Winding Pipe Extrusion Machinery,HDPE Hollow Wall Winding Pipe Extrusion Machine,HDPE Large Diameter Hollow Wall Winding Pipe Extrusion Line,Hollow Wall Winding Pipe Production Line,HDPE Hollow Wall Winding Pipe Making Machine, President of our company, with whole staff, welcomes all buyers to visit our company and inspect. Let us cooperate hand in hand to make a good future.

Hollowness Wall Winding Pipe Extrusion Machinery, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we've got a pleasant and long terms business together!!!

Hot Products

Pe Pipe Extrusion Machine

Qingdao comrise machinery co.,ltd is a Chinese manufacture and supplier for pe pipe extrusion machine, using our extruder machine is cost-effective because it reduces the need to purchase pipes and tubes from external suppliers. This can significantly reduce production costs, resulting in higher profits. Moreover, the pe pipe extrusion machine's maintenance costs are relatively low, making it a viable long-term investment.Three layer hdpe co extrusion pipe machine line

Comrise PE pipes are commonly used for urban water supply, transportation of natural gas and gas, food and chemical industries, transportation of ore and mud, replacement of cement pipes, cast iron pipes, and steel pipes.china pipe factory 315-630mm three layer hdpe co extrusion pipe machine line price good. Ppr pipes are widely used in the fields of building water supply and drainage, urban and rural water supply and drainage, urban gas, electricity, and fiber optic cable sheaths, as well as in the construction, municipal, industrial and agricultural sectors, industrial fluid transportation, and agricultural irrigation.Caterpillar Pipeline Machinery

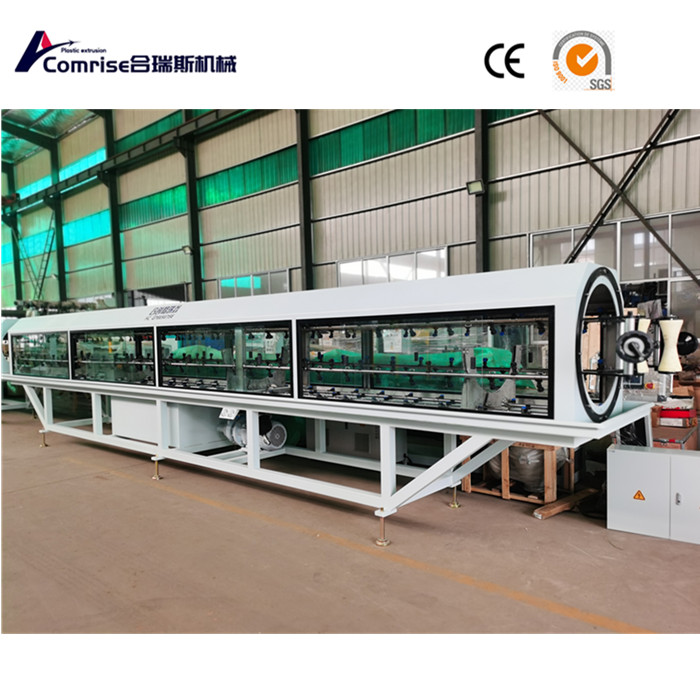

Comrise Machinery is your go-to supplier for top-quality PVC and HDPE caterpillar pipeline machinery. With comrise state-of-the-art technology, customized solutions, and user-friendly design, you can't go wrong with choosing us for your caterpillar pipeline machinery needs. Contact us today to learn more about how we can help you achieve your goals!PVC pipe extrusion machine

Comrise is a professional PVC pipe extrusion machine supplier, and also supplies full ranges of PVC pipe making machines, which apply for U-PVC, C-PVC, M-PVC, O-PVC material. The PVC pipe extrusion line includes conical twin screw extruder, spiral die head, vacuum tank, water tank, haul-off, no-dust cutter or planetary cutter, belling machine with O-ring sockets or rectangular sockets or U types of sockets. Our PVC pipe machine can make pipes ranging from 16mm to 630mm, wall thickness range of 1-30mm. If you are interested in our PVC pipe extrusion machines, Contact us and get a free quote now.High Speed Single Wall Corrugated Pipe Prodction Line

Comrise factory series of plastic High Speed Single Wall Corrugated Pipe Prodction Line meticulously developed by our company, through the gear drive mould, water cooling in the water trough of the forming machine so that the production of the pipe molding speed, uniform corrugated shape, smooth inside and outside the wall. The production speed is 8-15 meters per minute.Inner Flat Emitter Type Drip Irrrigation Tape Making Machine

1. Using different or equivalent models of plastic extruders for synchronous extrusion, and using variable frequency speed control to control the extrusion amount, to ensure stable and reliable operation of the production process, flexible adjustment, and reduce energy consumption. Inner Flat Emitter Type Drip Irrrigation Tape Making Machine 2. The extruder screw and barrel are forged, quenched and tempered, and treated with 38CrMoAlA nitriding. Then, spray hard double alloy on the surface of the screw to improve its hardness and extend its service life. Meanwhile, the screw structure adopts a new type of structure, which is particularly suitable for PE recycled materials and has better plasticizing effect. 3. The double-layer composite drip irrigation tape forming mold adopts double-layer co extrusion hot runner center spiral feeding, cast aluminum air ring pre cooling, and uses far-infrared diameter measuring device (built-in air pump, no external air source required) for measurement, ensuring high film tube strength and uniform thickness. 4. Drip irrigation tape is formed using a separate vacuum forming device, ultimately meeting the standard specifications of drip irrigation tape. 5. After molding and air cooling, it enters the stainless steel water tank and undergoes circulating and shaping water cooling simultaneously. 6. Drip irrigation belt traction adopts drum type traction and variable frequency speed regulation, which is conducive to better and timely adjustment of production line operation. 7. The coiler adopts a three station center tension winding and is equipped with a far-infrared electronic counting device to ensure the accuracy of meter counting. At the same time, it is equipped with an automatic alarm device. When the set length is reached, it will automatically sound an alarm and replace the coil. 8. The entire production equipment adopts intelligent digital electrical control, which is easy to operate.