China Double Screw Plastic Extruder Manufacturer, Supplier, Factory

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for Double Screw Plastic Extruder,Double Screw Extruder,Double Screw Extruder Machine,Extruder Double Screw,Double Screw Extruder for Pipe, Standing still today and seeking into the longer term, we sincerely welcome customers all over the environment to cooperate with us.

Double Screw Plastic Extruder, In the increasingly competitive market, With sincere service high quality merchandise and well-deserved reputation, we always supply customers support on items and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we'll become long-term partners.

Hot Products

Drip Irrigation Pipe Machine Line

COMRISE High quality drip irrigation independent machinery Drip irrigation line we manufacture. comrise new production line has been launched, with better quality and faster speed. It can quickly replace droppers. Come in and take a look Standard output: Drip Irrigation Pipe Machine Line For each geometric shape of a given flat dropper, a kit can be used to replace the flat dropper output.china top factory machine supplierLarge Diameter Double Wall Corrugated Pipe Machine

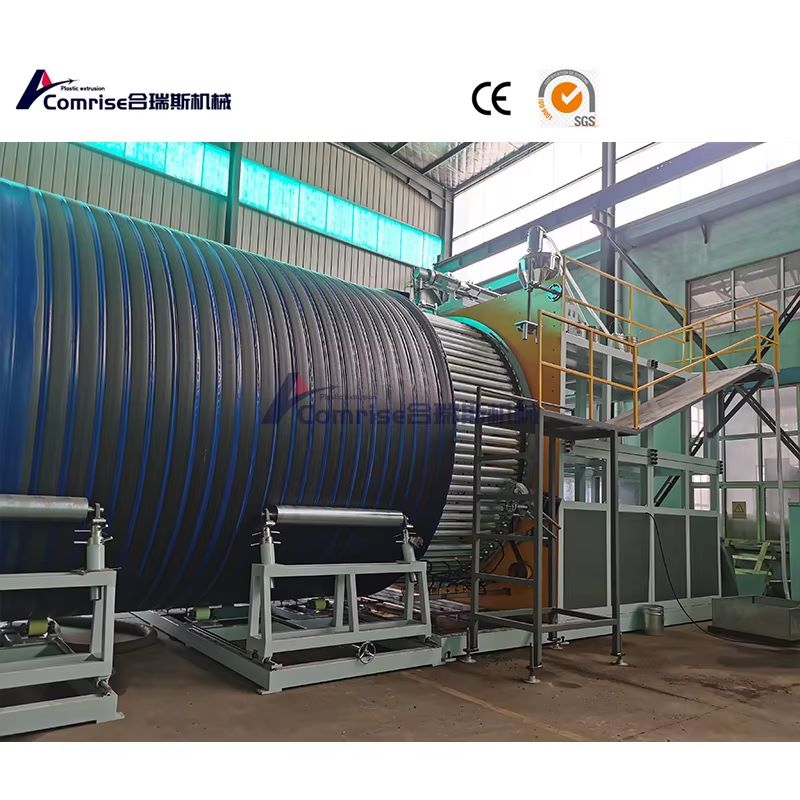

Large diameter double wall corrugated pipe machine is a mature product with advantages such as light weight, low cost, corrosion resistance, good ring stiffness, and good elasticity. Our company has been developing PE double wall corrugated pipe extrusion production line for more than 20 years. We have a complete series of double wall corrugated tube machines: horizontal, vertical, and shuttle. Our machines can process various materials, including HDPE, PP, PVC, etc.Corrugated Pipe Extrusion Line

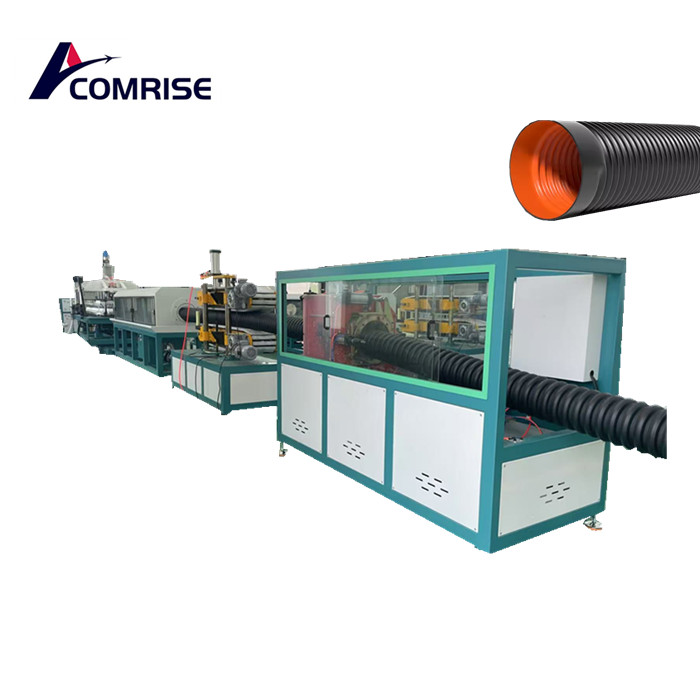

Comrise corrugated pipe extrusion line is a specialized manufacturing system used to produce corrugated plastic pipes, which are widely used in drainage, sewage, electrical conduits, and telecommunications. The Corrugated Pipe Extrusion Line process involves extruding molten material (typically HDPE, PP, PVC, or other polymers) and forming it into a corrugated structure for enhanced strength and flexibility.Industrial Water Chiller

Comrise Machinery is a leading supplier of industrial water chillers in China, providing solutions for cooling manufacturing processes and data center cooling. At Comrise Machinery, we are committed to providing our customers with the highest quality products and services. Comrise team of experienced technicians and engineers provides comprehensive technical support and customized solutions to meet the specific needs of their clients to ensure their satisfaction.HDPE ABA Co Extrusion Production Line

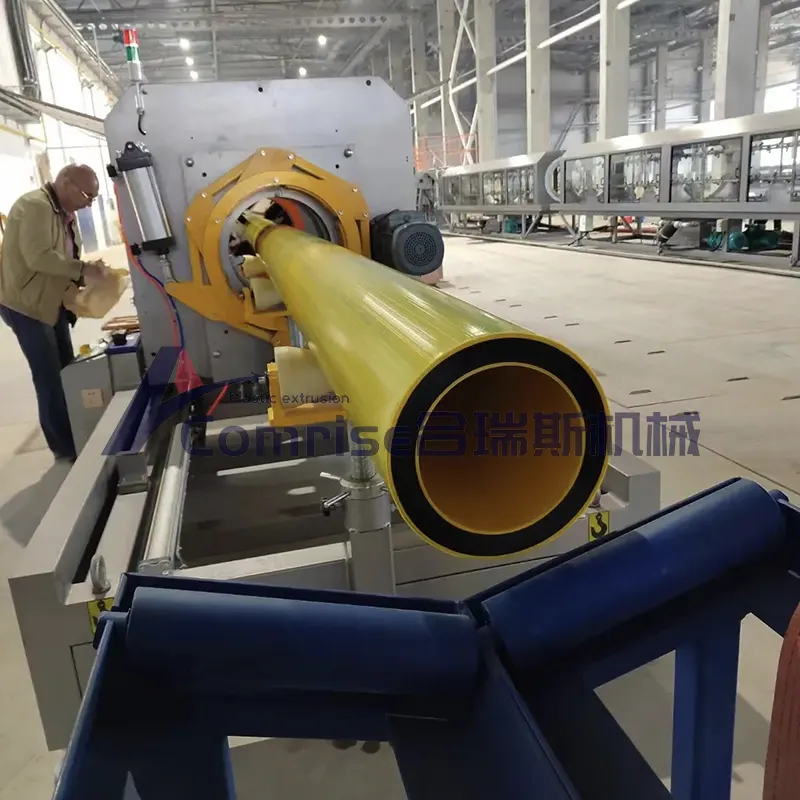

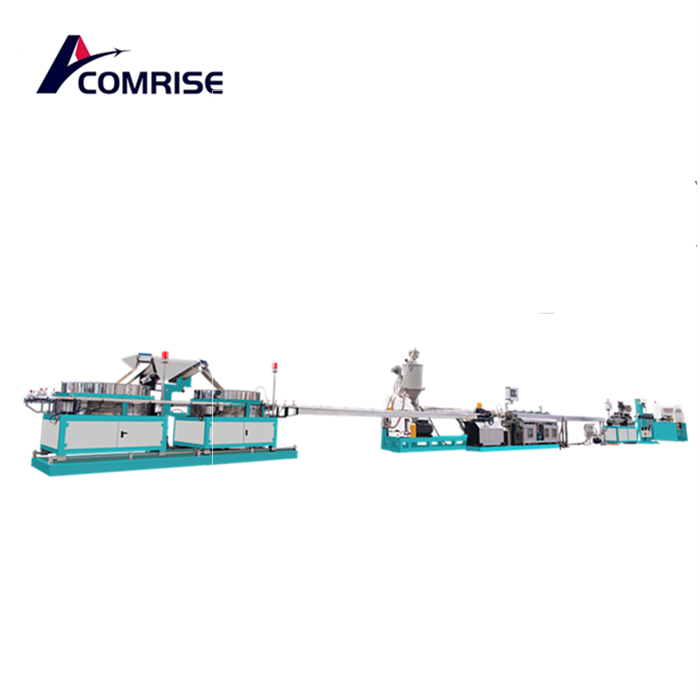

Comrise factory HDPE ABA Co Extrusion Production Line can be used for HDPE large-diameter gas and PE water pipes, 110-315mm ABA Co extrusion production line,with excellent rigidity and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress crack resistance, creep deformation resistance, hot keys, etc. Therefore, this pipeline production line is the preferred gas and water pipe for urban and suburban pipeline systems, and large-diameter HDPE pipes are beginning to play a very important role in urban water and gas supply systems.PVC Wood Plastic Door Panel Production Line

Comrise Machinery, a professinal Chinese manufacture for PVC Wood Plastic Door Panel Production Line and PVC Wood Plastic Door Panel Production Line supplier. Comrise understand that each client has unique needs when it comes to their PVC Wood Plastic Door Panel Production Line. To that end, we offer tailored solutions that cater to specific requirements. Comrise team of experts works closely with clients to identify their production goals and customize their machinery to meet those targets. This approach has helped their establish long-lasting partnerships with their clients while delivering exceptional results.