HDPE ABA Co Extrusion Production Line

Send Inquiry

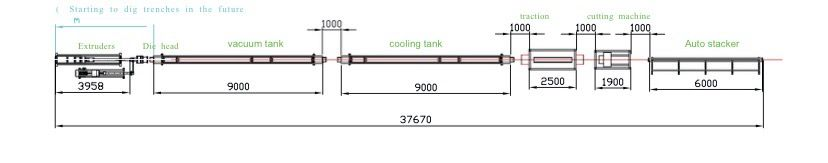

A. Process flow of PE pipe making machine/PE pipe production line

Raw materials+additives → mixing → vacuum feeder → hopper dryer → single screw extruder → color code extruder → mold and calibrator → vacuum forming machine → cooling tank → trailer → cutting machine → winding machine

B. Characteristics

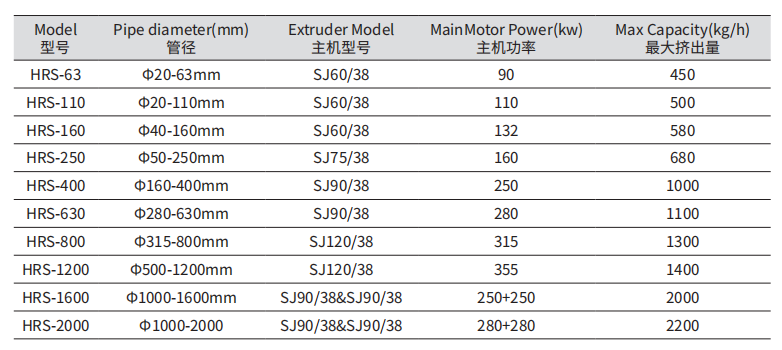

Capacity: HDPE ABA Co Extrusion Production Line Single screw extruder, suitable for processing high-capacity PE resin, with a maximum capacity of 2200 kg/h.

Diameter: from 16 to 2000mm

Adopting reasonable design, absorbing safety production technology, and obtaining CE certificate

C. Description

This HDPE ABA Co Extrusion Production Line/PPR pipe making machine/PPR pipe production line can be used for HDPE large-diameter gas and PE water pipes, with excellent rigidity and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress crack resistance, creep deformation resistance, hot keys, etc. Therefore, this pipeline production line is the preferred gas and water pipe for urban and suburban pipeline systems, and large-diameter HDPE pipes are beginning to play a very important role in urban water and gas supply systems.

D. Technical parameters

The newly produced 110-315mm HDPE pipe in the workshop is currently being processed on the production line and is about to be completed

110-315mm ABA Co extrusion production line

There is currently a 20-1200mm HDPE pipe production line in the workshop we manufacture that is being processed and manufactured.

If you want to know more, please contact

GET A QUOTATION NOW