China HDPE Pipe Productio line Manufacturer, Supplier, Factory

We have now a specialist, efficiency staff to provide good quality company for our consumer. We normally follow the tenet of customer-oriented, details-focused for HDPE Pipe Productio line,110-315mm HDPE pipe extrusion line,Plastic HDPE PP Pipe Machine,HDPE Pipe Machine,HDPE Pipe Extrusion Production Line, With superb service and quality, and an enterprise of foreign trade featuring validity and competitiveness, that will be trusted and welcomed by its clients and creates happiness to its employees.

HDPE Pipe Productio line, Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, remember to do not hesitate to contact us.

Hot Products

PP/PS Blister Packaging Sheet Production Line

Comrise machinery co.,ltd is a leading supplier for PP/PS Blister Packaging Sheet Production Line and China top manufacture for PP/PS Blister Packaging Sheet Production Line. The high quality plastic PP/PS Blister Packaging Sheet Production Line produced sheets after further processing are mainly used for hard packaging of fruits, vegetables, and food, outer packaging of cosmetics, hardware tools, children's toys, and containers for agricultural planting and seedling cultivation.Corrugated Pipe Machine

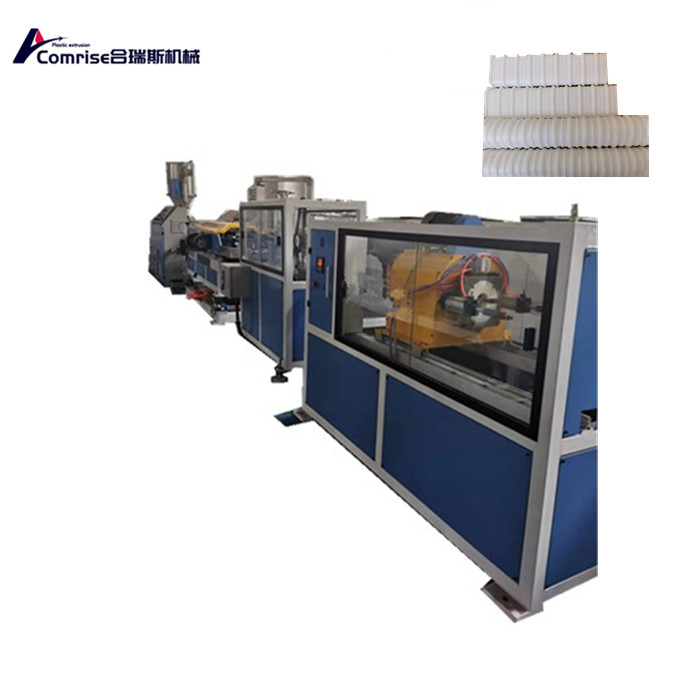

We are Comrise machinery specialized on corrugated pipe machine, there are single wall corrugated pipe machine, double wall corrugated pipe machine, corrugated drainage pipe machine, spiral corrugated pipe extrusion machine etc., comrise have normal speed and high speed corrugated pipe machine, also the forming molds can iron material or aluminum material as to customer requirements.PP Hollow Formwork Board Machine

Qingdao Comrise Machinery is a professional manufacturer of pp hollow formwork board machine that can provide you with high-quality and stable pp hollow formwork board machine Machines with different specifications. Our machines are designed with mature technology and experience sale team and production team.High efficiency HDPE pipe production line factory price

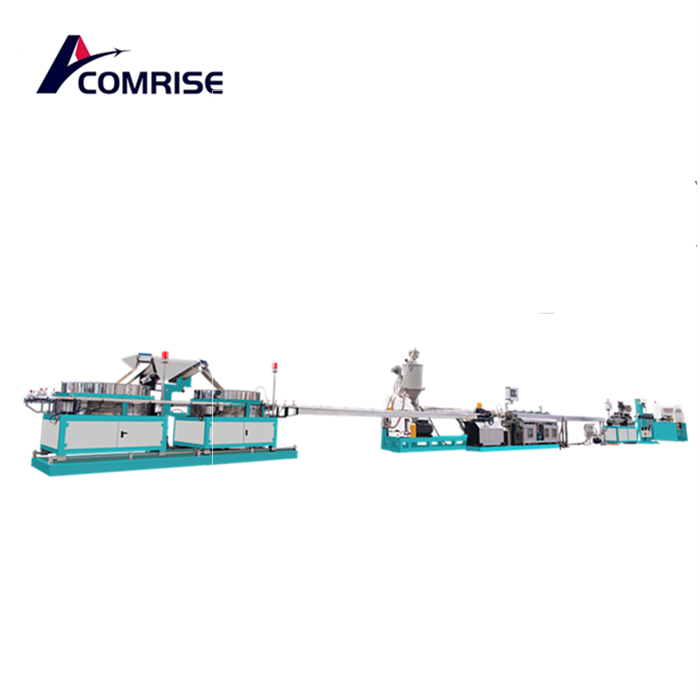

QINGDAO COMRISE MACHINERY main production line including High efficiency HDPE pipe production line factory price, PE large-diameter hollow-wall winding pipe production line, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line, the plastic coated corrugated pipe production line, PE black jacket insulation pipe production line and PE sheet/board production line. HC has more than 20 kinds new products, which are sold world widely such as Russia, Southeast Asia, Middle East, and Africa.PPR Pipe Machine

PPR pipe machines are used to produce polypropylene random copolymer (PPR) pipes, which are widely used in cold and hot water systems, heating systems, and other applications. Depending on production requirements, these machines can produce pipes in various sizes, commonly ranging from 16-63mm or 20-110mm in diameter. Additionally, PPR pipes can be single-layer or three-layer structures, depending on the application.PE Bridge Prestressed Carbon Spiral Corrugated Pipe Machine

COMRISE The special separated mixing screw and standard designed mold have a spiral structure and reasonable channels, PE Bridge Prestressed Carbon Spiral Corrugated Pipe Machine supplier,suitable for producing pipes with smooth inner and outer surfaces. The spiral distribution method, different bodies, and large flow space ensure that the melted material has sufficient residence time. The optimal low melting temperature results in low internal stress in the pipeline and smooth inner and outer surfaces. Unique sizing cooling method, capable of producing pipes with a range of 50-200 millimeters, with a production speed of up to 0.6-1.5 meters per minute