Call Us

+86-13780696467

Email Us

sales@qdcomrise.com

China Insulation Pipe Making Machine Manufacturer, Supplier, Factory

In the past few years, our firm absorbed and digested highly developed technologies equally at home and abroad. Meanwhile, our business staffs a group of experts devoted on the growth of Insulation Pipe Making Machine,Pipe Insulation Machine,Flexible Rubber Foam Pipe Insulation Machine,Pipe Insulation Tape Machine,Air Conditioner Pipe Insulation Machine, We warmly welcome pals from all walks of everyday living to cooperate with us.

Insulation Pipe Making Machine, We warmly welcome your patronage and will serve our clients both at home and abroad with items of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Hot Products

PE Pipe Production Line for Irrigation

If you are in search of an efficient and reliable irrigation solution, look no further than the professional supplier comrise PE Pipe Production Line for Irrigation. With the latest technology and quality materials, comrise production line is designed to meet all your irrigation needs.Corrugated Optic Duct Pipe Extrusion Machine

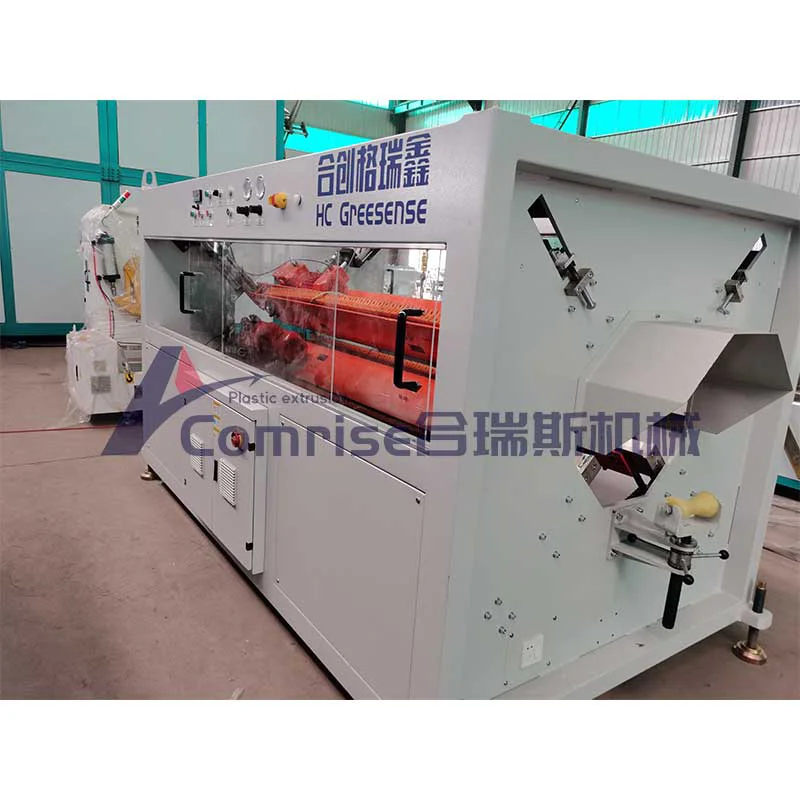

Advantages and functions of cluster tube and COD tube equipment: advantage: High production and processing efficiency. • Stable performance and reliable quality.Corrugated Optic Duct Pipe Extrusion Machine Function: Mainly used for the production and installation of pipeline systems, providing stable and reliable pipeline connections. Can meet the requirements of different engineering applications and ensure the smooth operation of pipelines. 1. The pipe is extruded by the first extruder and then enters the twisting machine, while the basket co extrusion mold forms the shape of the pipe. 2. The pipe material is mainly made of high-density PE.20-110mm PVC Pipe Machine

If you are searching for a professional and reliable 20-110mm PVC Pipe Machine extrusion line manufacturer, look no further than Comrise Machinery. With Comrise experience, expertise, and dedication to quality, Comrise are confident that they can provide you with the ideal solution for your plastic 20-110mm PVC Pipe Machine extrusion needs. Contact us today to learn more.Hollow wall winding pipe machine line

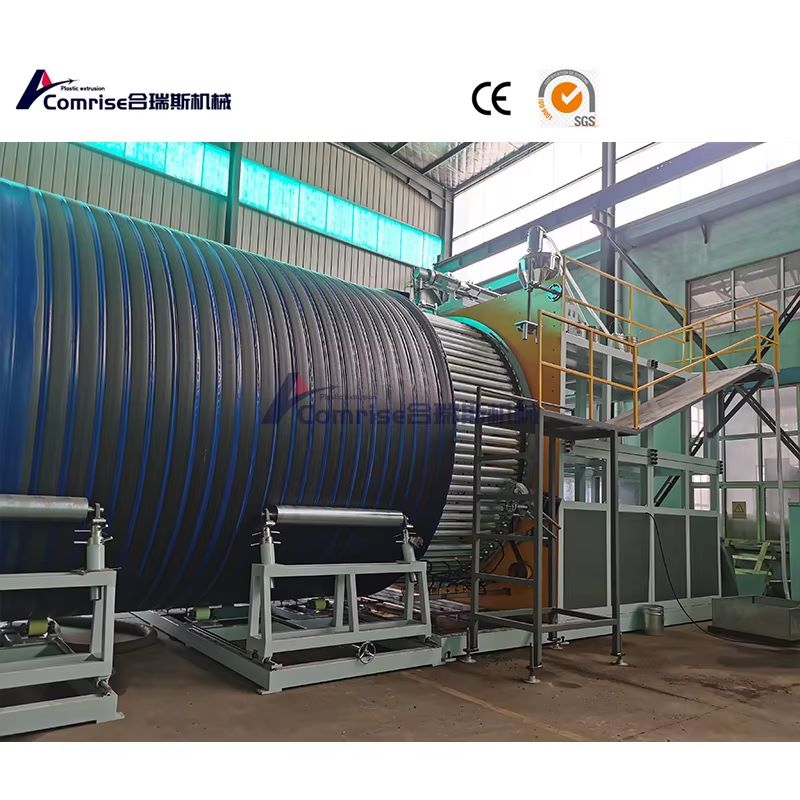

Comrise china fasctory supply HDPE hollow wall wrapped pipes have been successfully used as drainage pipes to replace cement pipes and cast iron pipes, and have broad market prospects. Our company is an authoritative manufacturer of large-diameter hollow wall winding pipe production lines in China,Hollow wall winding pipe machine line with strong technical advantages and rich experience in implementing production and installation. The equipment design is advanced, the configuration is high-end, the operation is reliable, the service life is long, and the output of the same model is far higher than the industry level. Especially for ultra large diameter models, we have rich experience and can meet the needs of large high-end customers at home and abroad. The performance indicators of the production line have reached the international leading level.Pe Pp Pipe Making Machine

China supplier comrise pe pp pipe making machine is an advanced piece of equipment that is designed to produce high-output HDPE PE pipes and tubes of various sizes effortlessly. The pe pp pipe making machine's unique features, including its increased efficiency, enhanced durability, user-friendly interface, wide range of sizes, and cost-effectiveness, make it an excellent investment for those in the pipe and tube manufacturing industry. With our pe pp pipe extruder machine, our customers can produce high-quality pipes and tubes with less effort, increased efficiency, and higher profits.PP Hollow Building Formwork Extrusion Machine

Comrise Machinery is a leading manufacture for PP hollow building formwork extrusion machines. Comrise offer a complete range of solutions for producing high-quality PP hollow building formwork that is strong, durable, and environmentally friendly.

Related Search

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy