China Corrugated Pipe Slitting Machine Manufacturer, Supplier, Factory

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Corrugated Pipe Slitting Machine,Corrugated Pipe Machine,Corrugated Pipe Making Machine,Double Wall Corrugated Pipe Machine,Single Wall Corrugated Pipe Machine, We believe we'll become a leader in building and producing top quality merchandise in the two Chinese and international markets. We hope to cooperate with much more close friends for mutual gains.

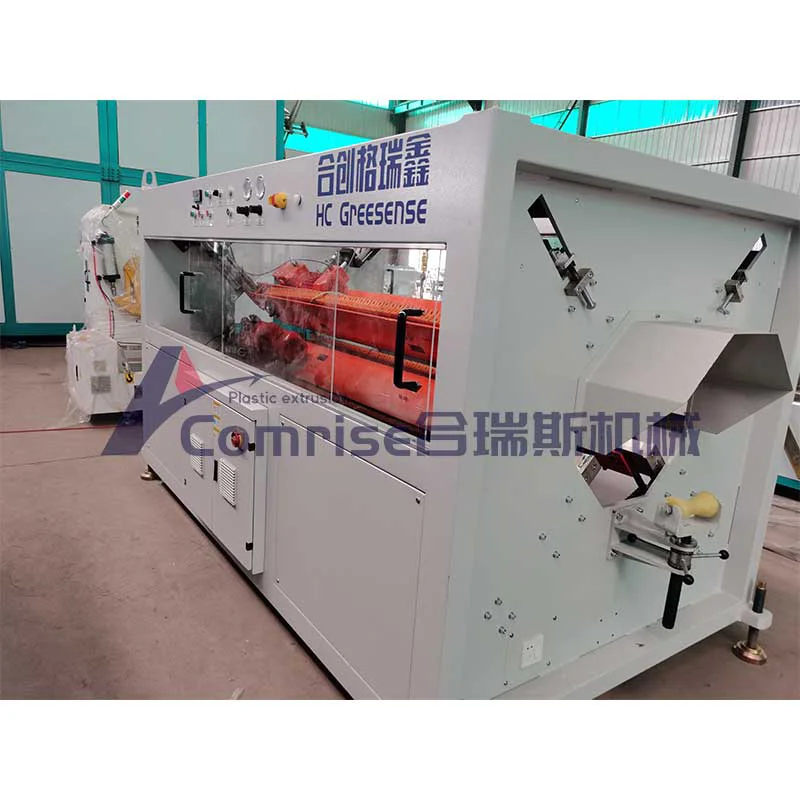

Corrugated Pipe Slitting Machine, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

Hot Products

PS Plastic Sheet Production Line/PS Blister Sheet Production Machine

PS Plastic Sheet Production Line/PS Blister Sheet Production Machine PP/PS single-layer sheet, PS co extruded dual color sheet, PP double-sided high transparency sheet and other sheets used in the vacuum packaging industry PP Stationery Sheet Production Line PP transparent sheet, frosted sheet (coarse sand, fine sand), two-color sheet and other sheets used in the stationery packaging industry.3600mm HDPE Hollow Spiral Winding Pipe Machine

Comrise 3600mm HDPE Hollow spiral winding pipe machine is a state-of-the-art extrusion production line specialized in manufacturing large diameter hollow spiral winding pipes made of high-density polyethylene (HDPE) material. HDPE Hollow spiral winding pipe machine can produce pipes with diameters of up to 3600mm and has a unique spiral winding design that ensures maximum strength and durability for a wide range of applications. The HDPE Hollow spiral winding pipe machine utilizes advanced technology for precise temperature and speed control, allowing for consistent and uniform production. With output rates ranging from 600-1000kg/h, this HDPE Hollow spiral winding pipe machine is ideal for large-scale production of HDPE pipes used in industrial and municipal sewage systems, drainage systems, and other applications. Our company is dedicated to providing top-quality products and services, backed by a team of experienced professionals committed to meeting our customers' needs and exceeding their expectations.New Air Duct Double Wall Corrugated Pipe Machine

Qingdao Comrise Machinery is a professional supplier for plastic corrugated pipe machine, such as single wall corrugated pipe machine,New air duct double wall corrugated pipe machine from 40mm upto 160mm, 110-315mm, molds material adopt iron or aluminum according to customer different requirements. This set high quality New air duct double wall corrugated pipe machine can make dwc pipe from OD40mm upto 160mm, two single screw extruders, durable forming machine with 60pairs of forming molds, customer can choose online socket or not on same machine, behind with cutting machine or winding machine.Pe Pipe Production Machine

The China Comrise is a professional factory offers excellent pe pipe production machine, with good after-sales service, ensuring that you are fully supported throughout the entire production process. Comrise team of experts is always ready to assist you with any questions or concerns you may have. So why wait? Upgrade your pe pipe production machine production line today with the China Comrise. Contact us now to learn more about our comprehensive range of extruder machines and related services.Hdpe Pipe Manufacturing Machine

Qingdao Comrise Machinery specializes in the design, development, and manufacturing of high-quality HDPE (High-Density Polyethylene) pipe production lines and Hdpe Pipe Manufacturing Machine. With years of experience in the plastic machinery industry, we have established ourselves as a trusted name in providing innovative and efficient solutions for HDPE pipe manufacturing machine. Our team of skilled engineers and technicians is committed to delivering machinery that meets the highest international standards. We pride ourselves on our ability to offer customized solutions tailored to the specific needs of our clients, ensuring optimal performance and reliability.PP Multi-Layer Sheet Production Line

Comrise machinery is a professional manufacture for PP PE ABS HIPE TPE single layer or multi layers PP multi-layer sheet production line and supplier for plastic co extrusion machines.The high quality PP multi-layer sheet production line the produced sheets are mainly used for packaging fast food boxes, vegetables, food packaging boxes, cosmetics, hardware tools, children's toys, etc. after secondary heat forming.